Making method of large-scale cavity foaming part molding die and die structure thereof

A molding die and manufacturing method technology, applied in the molding field of other foam plastics, can solve the problems of large processing volume of upper and lower dies, high processing cost, long processing cycle, etc., achieve small processing volume, reduce processing allowance, and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

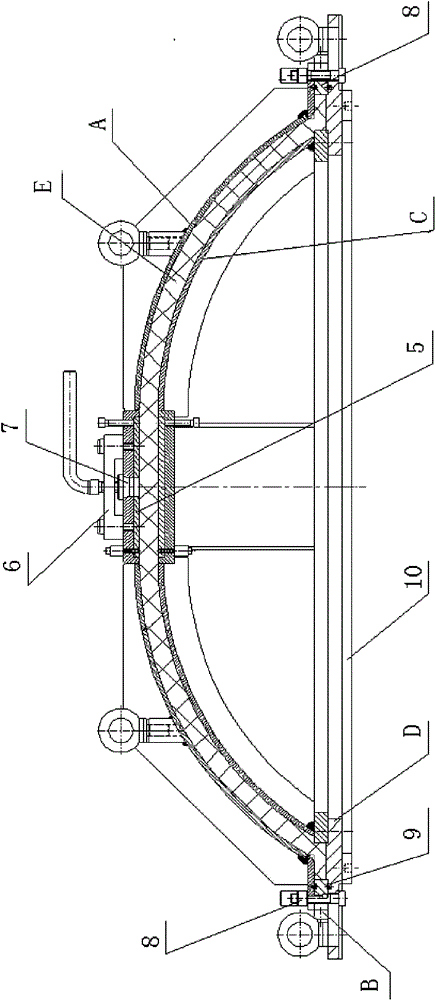

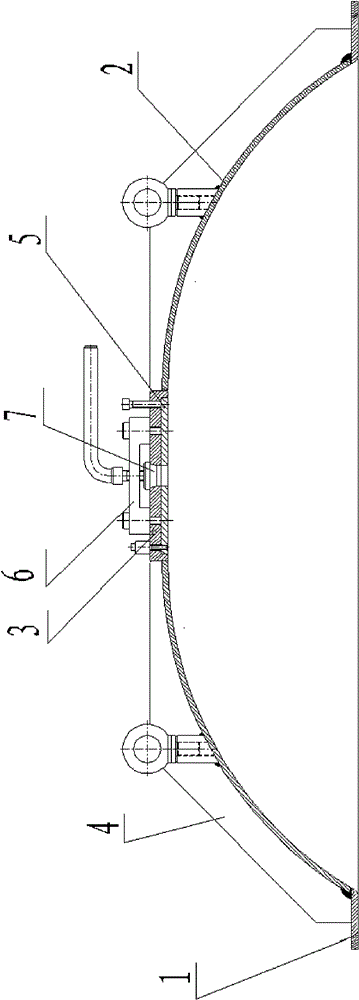

[0027] figure 1 It is a longitudinal sectional view of the large cavity foaming part molding die structure die of the present invention:

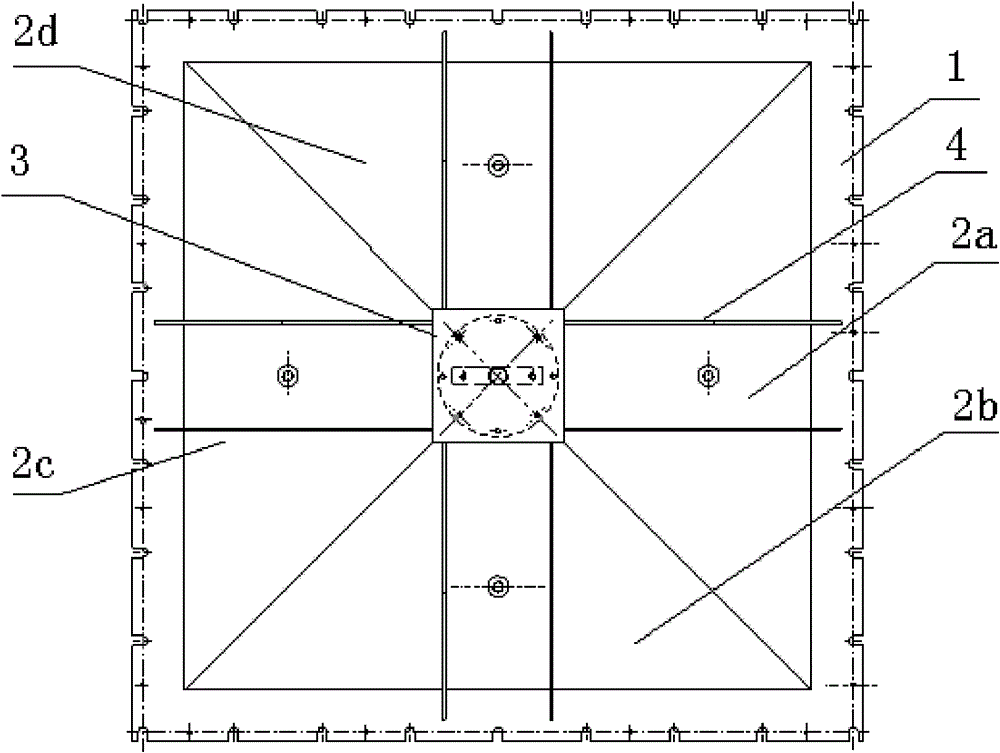

[0028] The structure of the large-cavity foamed part forming mold of the present invention includes an upper mold and a lower mold, the upper mold includes a concave mold body A and a chassis B, the lower mold includes a convex mold body C and a base D, and E is a large-cavity foamed part.

[0029] The inner side of the concave model body A has a groove, and the top plate 5 is placed in the groove, and the top plate 5 is connected to the top of the concave model body A by bolts; the top of the concave model body A is provided with a sprue, a sprue plug 7 and a movable pressure rod assembly 6. The pouring hole runs through the top of the concave model body A to the cavity, and the movable pressing rod assembly 6 is used to compress the pouring port plug 7 . The chassis B of the upper mold and the base D of the lower mold are connected by b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com