Improved structure of filter vat

An improved structure and filter barrel technology, applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems of easy oil leakage, reduced filtration efficiency, high cost, etc., to achieve easy installation and disassembly, improve drainage The effect of slag efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

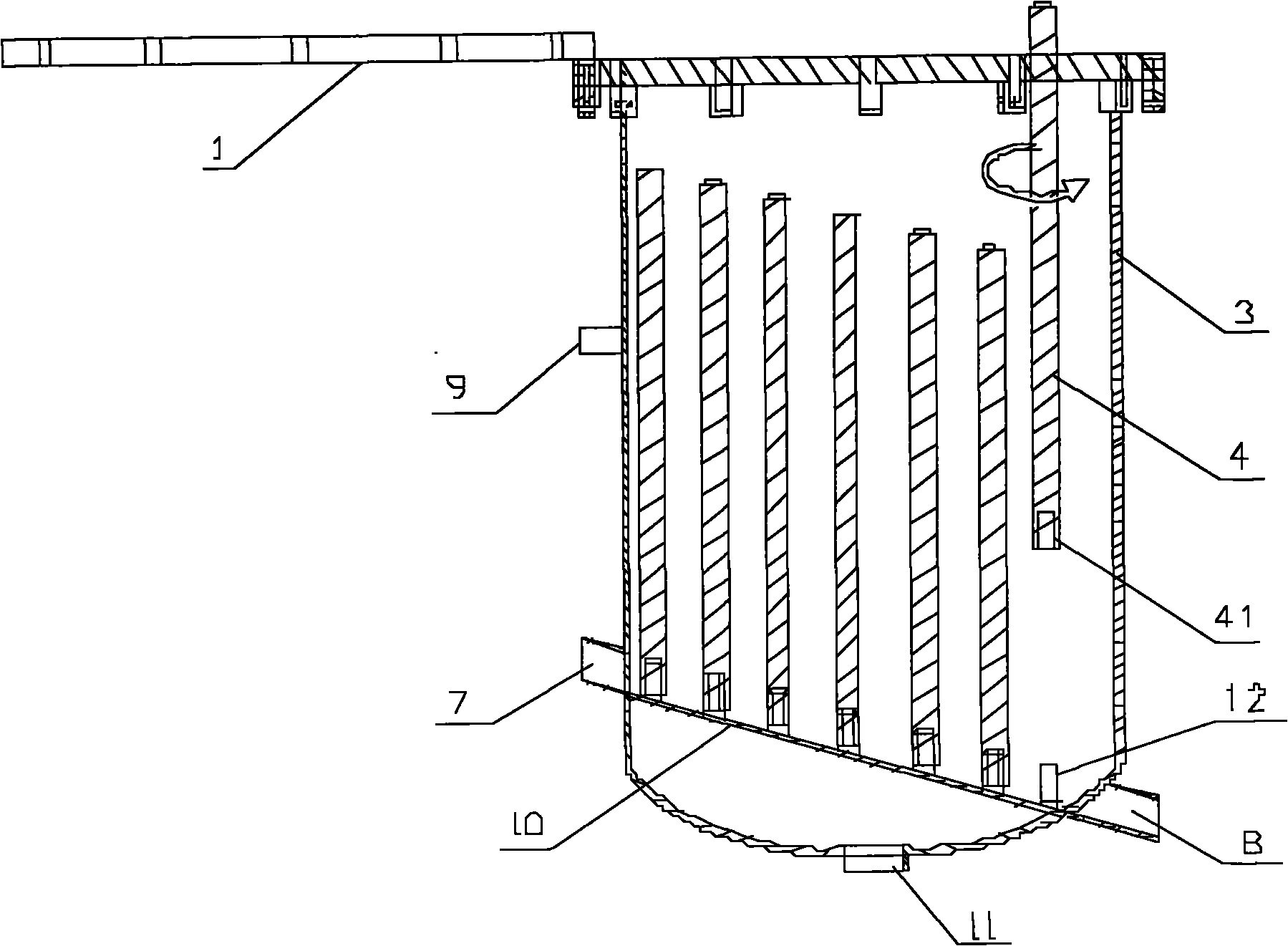

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and a preferred embodiment.

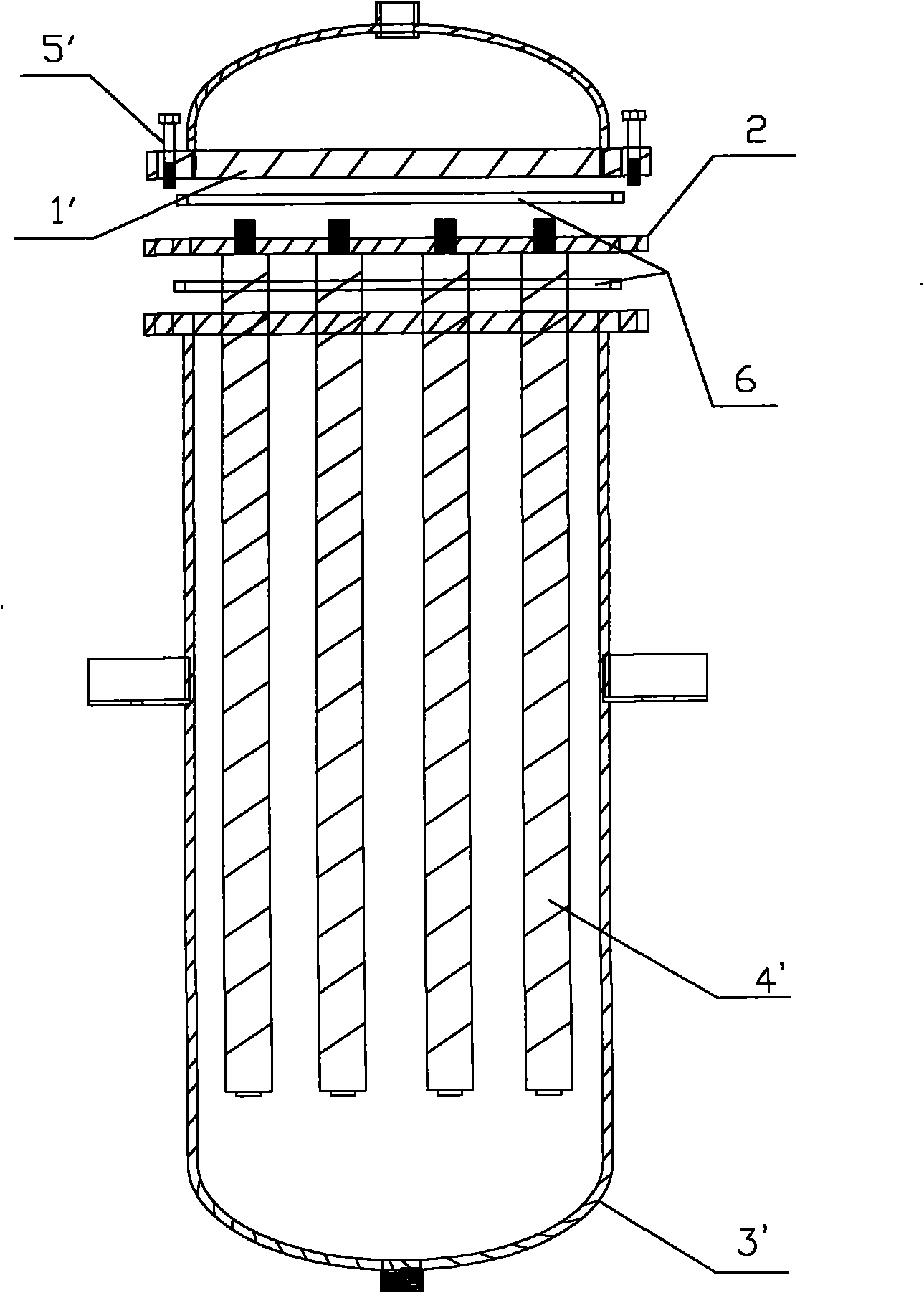

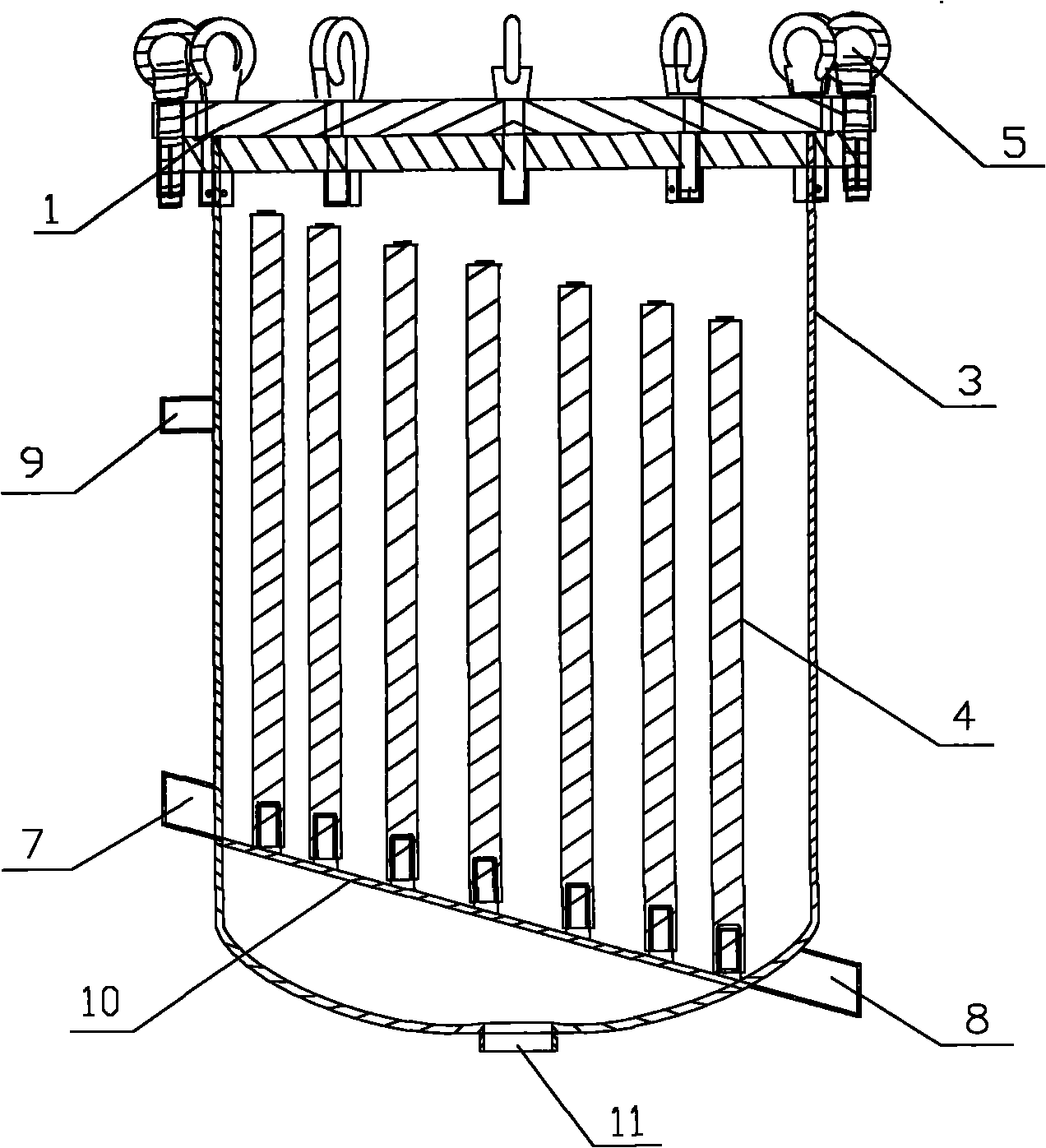

[0021] refer to figure 2 , the filter bucket includes a bucket body 3 and a bucket cover 1, and the bucket body cavity is divided into an upper cavity and a lower cavity by a partition (flange) 10 arranged at the bottom of the bucket body cavity, and the lower cavity is connected with the set The clean oil outlet 11 in the lower part of the barrel body is connected, and the upper cavity is respectively connected with the dirty oil inlet 7 and the dirt outlet 8 arranged on the barrel body. An opening is provided on the end surface, and the opening communicates with the lower cavity.

[0022] Preferably, the bung 1 adopts a plane cover plate, and the plane cover plate is fixedly connected with the bucket body through a plurality of fastening bolts 5 vertically passing through the plane cover plate and the peripheral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com