Pull-out guide for furniture and method for producing a pull-out guide

A technology for pulling out guide devices and furniture, applied in furniture parts, home appliances, applications, etc., can solve problems such as material consumption, sliding quality, and functional impact, and achieve the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

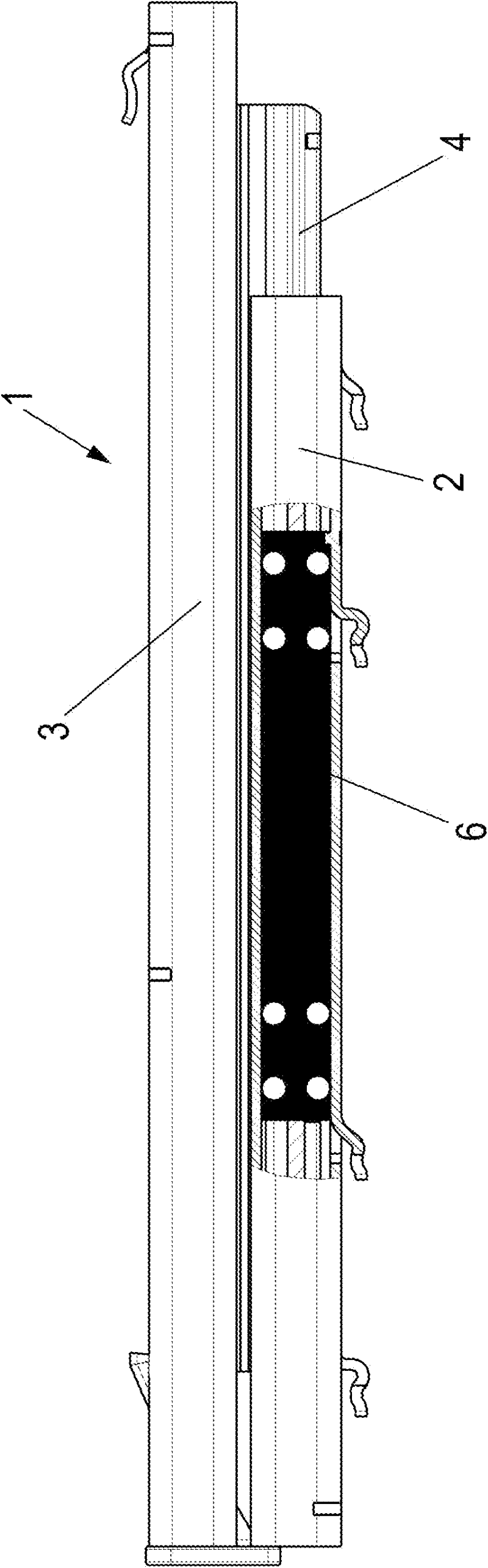

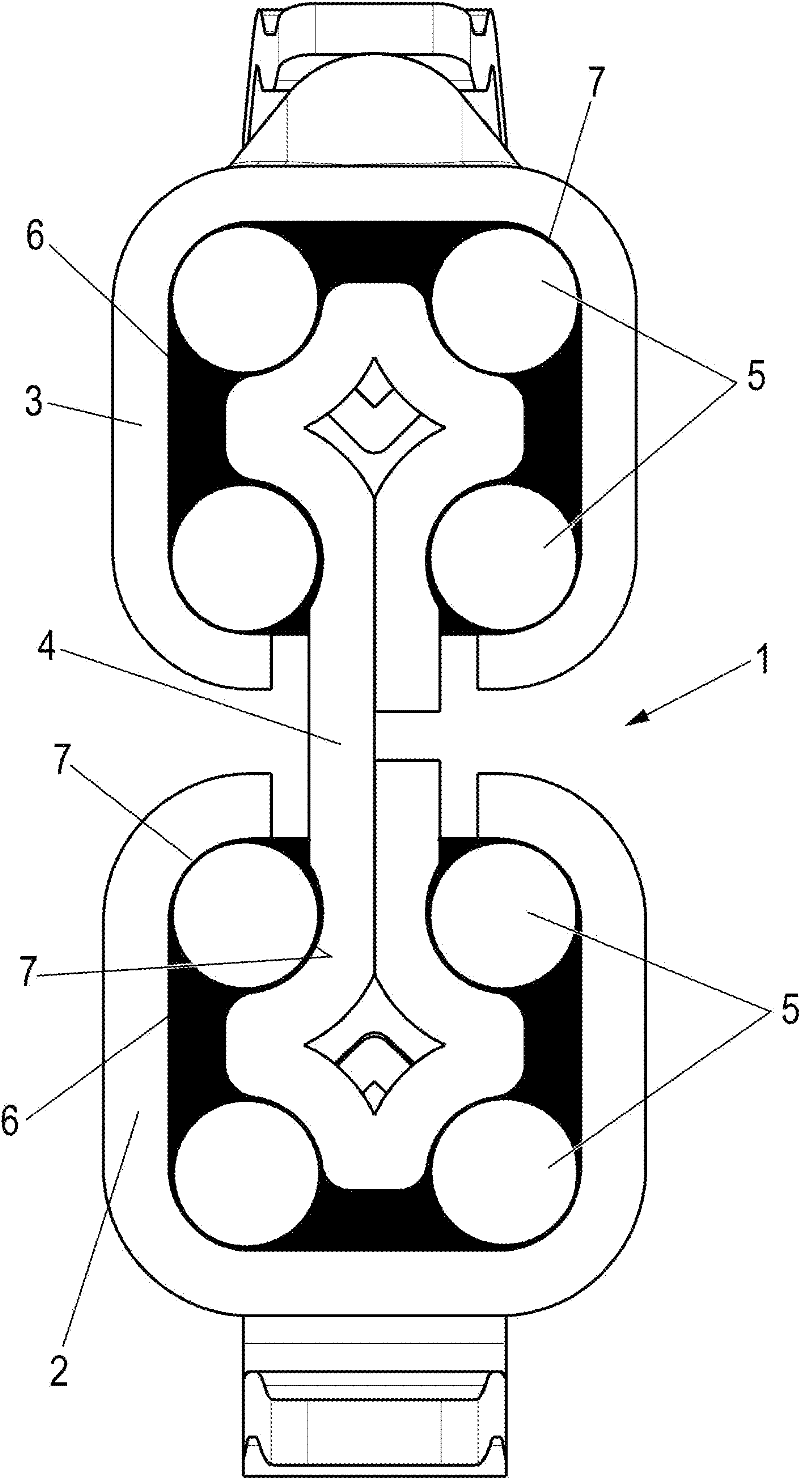

[0025] The pull-out guiding device 1 includes a guide rail 2 and a slide rail 3 that can be installed on a furniture body, and a drawer or other push-pull parts can be installed on the slide rail. The slide rail 3 is mounted via rolling bodies on the center rail 4 , which is in turn mounted displaceably on the guide rail 2 via rolling bodies 5 . The slide rail 3 can also be supported directly on the guide rail 2 without the center rail 4 via the rolling bodies 5 .

[0026] In the pull-out guide 1 , the rolling elements 5 are supported between the guide rail 2 and the intermediate rail 4 and between the intermediate rail 4 and the slide rail 3 in rolling element cages 6 which are integrally filled with lubricating made of medicated material. The rolling element cage 6 consists of a porous body made of sintered material or plastic in which oil is deposited as a lubricant. In this case, the rolling elements 5 are extrusion-coated with a lubricant-containing material.

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com