System and method for measuring diffusion flame frontal surface three-dimensional structure of motion fire source

A technology for spreading flames and three-dimensional structures, which is applied in measuring devices, fluid velocity measurement, velocity/acceleration/impact measurement, etc. It can solve the problem of the inability to obtain the three-dimensional spatial geometric characteristics of the flame front, the inability of the ignition source point to move, the running speed, and the trajectory Poor followability and other problems, to achieve the effect of flexible and convenient operation, realization of visualization and real-time, stable parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but the implementation and protection scope of the present invention are not limited thereto.

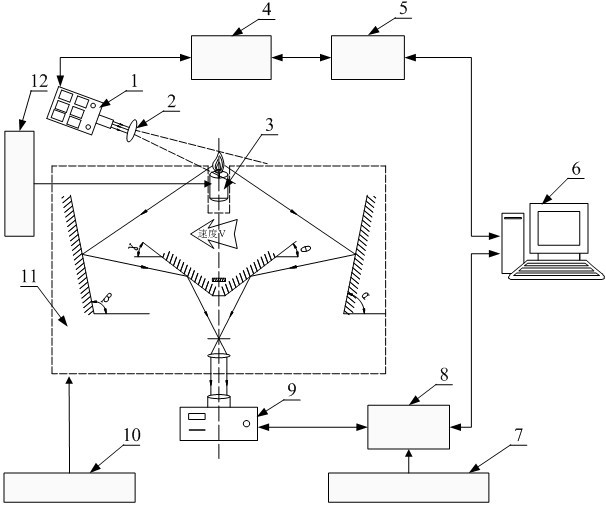

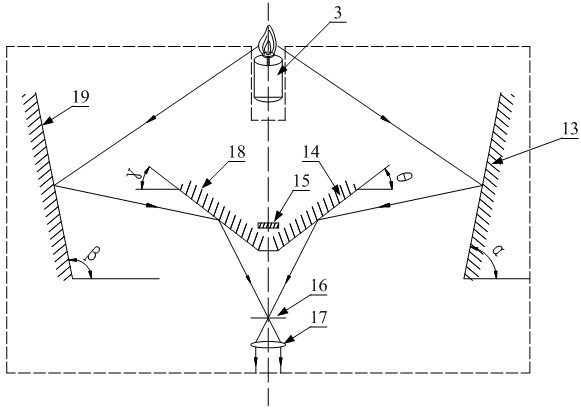

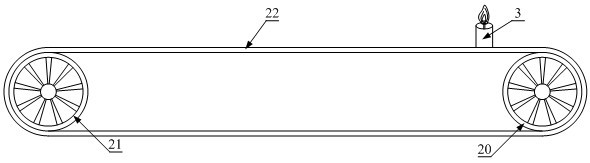

[0045] Such as figure 1 As shown, it is a structural schematic diagram of the three-dimensional structure measurement system of the moving fire source diffusion flame front in this embodiment. The measurement system includes a laser 1, a smooth lens 2, a diffusion burner 3, a synchronous controller 4, a stabilized voltage and lighting power supply 5, a computer 6, an acquisition control device 7, an image acquisition card 8, an image acquisition device 9, and an optical system adjustment Device 10 , imaging optical system 11 , speed control system 12 . The laser 1 can be a pulsed iridium-neodymium garnet laser 1 (Nd:Yag laser), and the Nd:Yag laser 1 is fixed on the floor through a support. The Nd:Yag laser 1 supplies the wide dynamic range laser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com