Building hollow block

A technology for hollow blocks and buildings, which is applied in the direction of buildings, building components, building structures, etc., and can solve problems such as small force transmission area and side wall damage due to bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

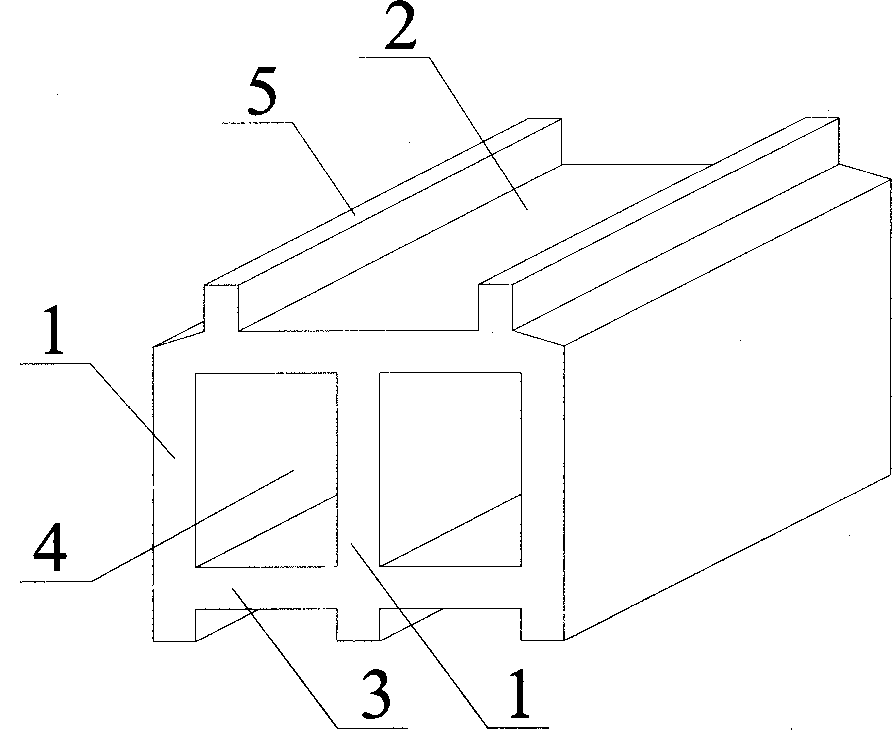

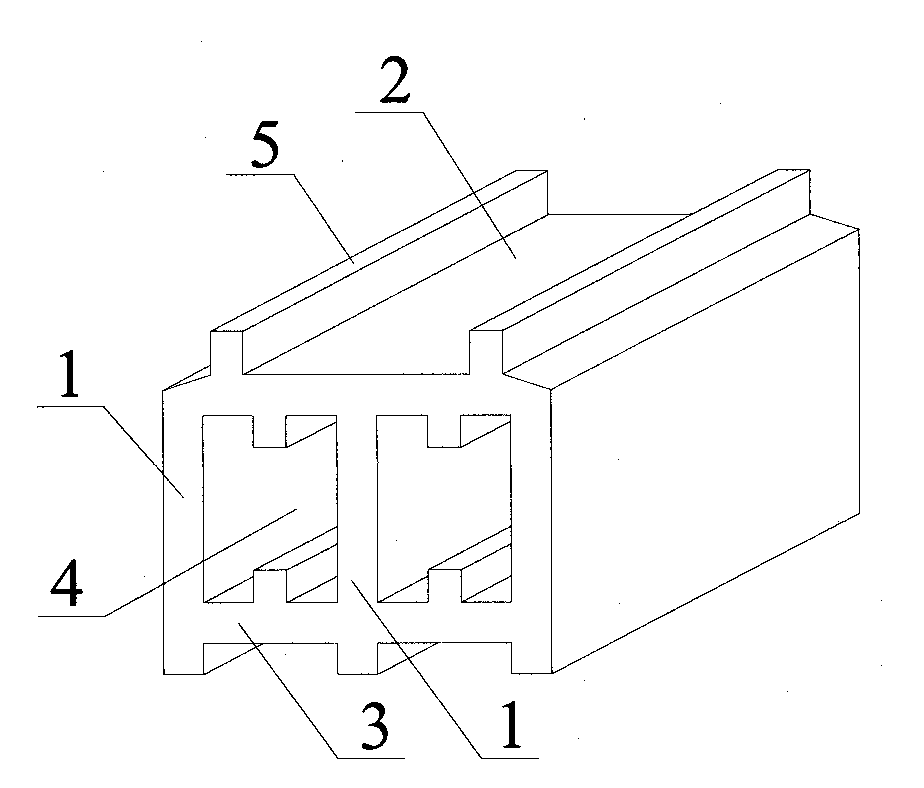

[0015] refer to Figure 1-Figure 10 , the building uses hollow blocks, which are composed of a top plate 2 and three or more supporting legs 1, and there are reinforcing ribs 3 between the supporting legs 1, and the top plate 2, two supporting legs 1, and reinforcing ribs 3 form a block space around 4. There are two or more convex ribs 5 on the top plate 2 . When building masonry, first apply mortar 6 on the top plate 2 above the middle support leg 1 of the lower block, then place the upper block on the lower block, and then place the horizontal groove and vertical groove formed by the upper block and the lower block. Smear or spray, extrude mortar 6 to fill in the joint, so that the wall is bonded into a whole. Due to the increase of the support leg 1, the force transmission area of the block increases, and at the same time, the load transfer from the upper block to the rib 5 and the top plate 2 of the lower block is reduced, so that the support leg 1 can be prevented from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com