Method for improving yield of ethanol produced by sugar beet fermentation

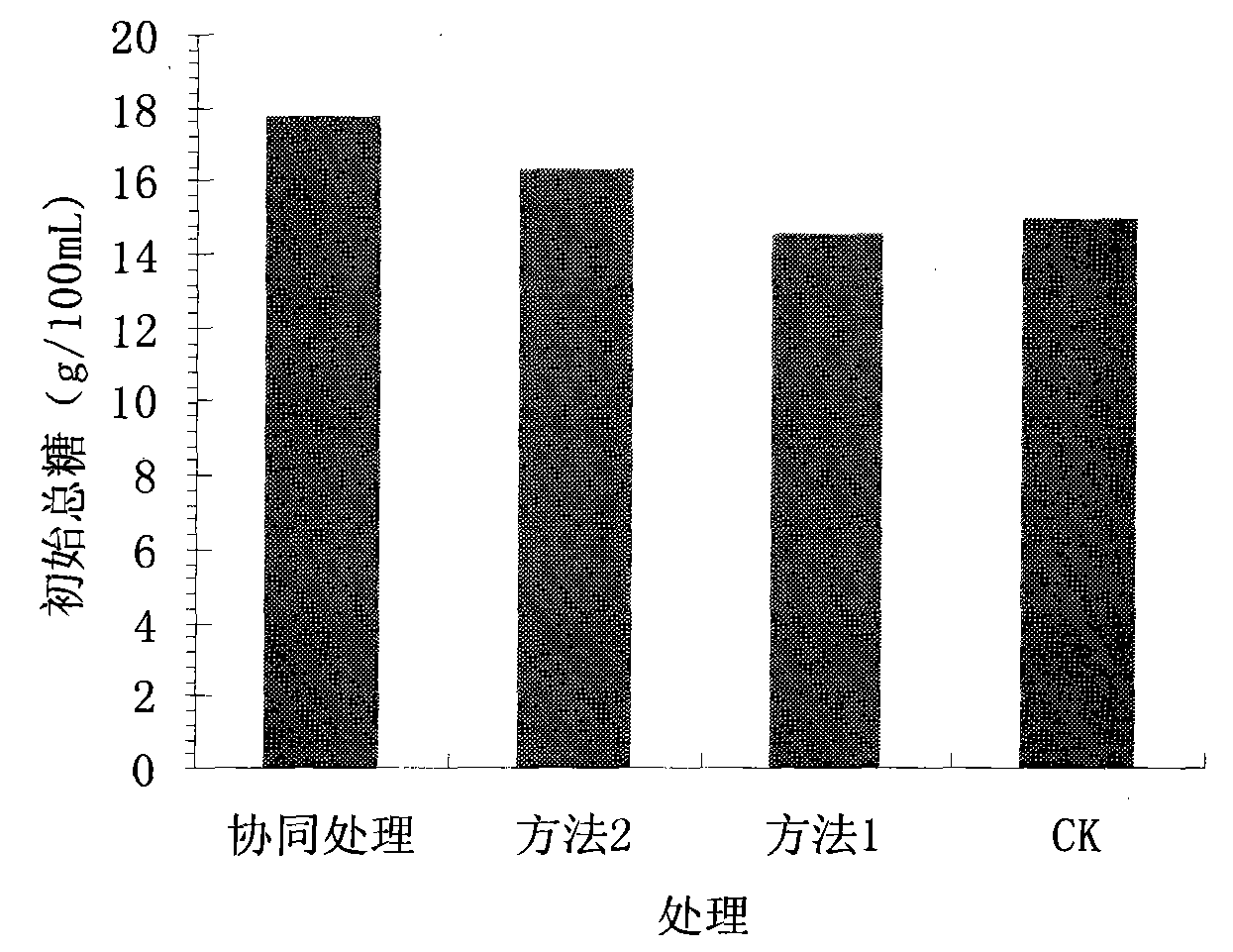

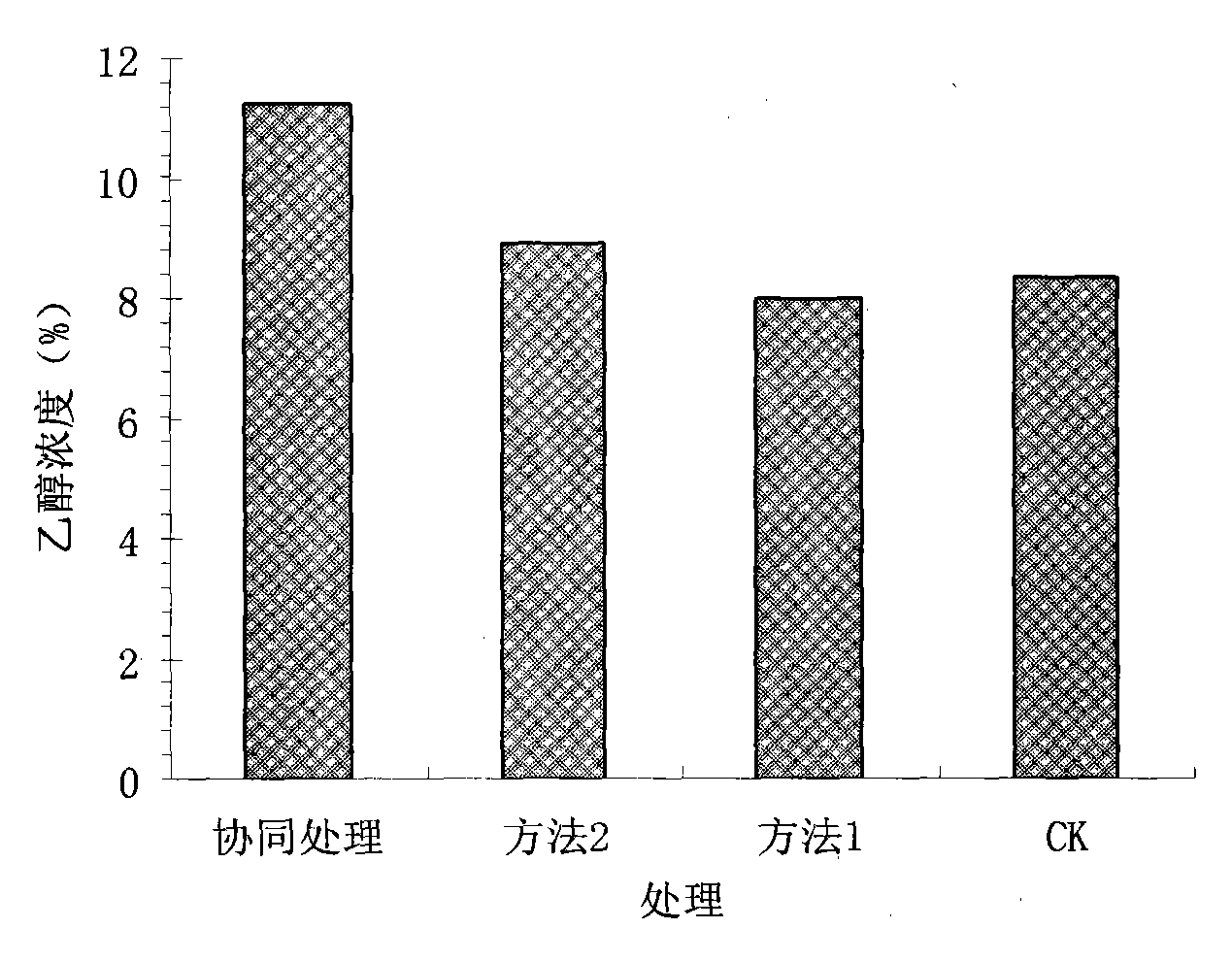

A technology for ethanol and sugar beet, applied in the field of fermentation engineering, can solve the problems of long fermentation time, high residual sugar in fermentation liquid, low fermentation efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] The invention provides a method for improving the yield of ethanol produced by sugar beet fermentation, comprising the steps of:

[0084] I. Preparation of Medium

[0085] (1) Yeast culture medium preparation: the dimensions of the material proportion involved in this step are all g / L.

[0086] a. Preparation of Pachysolen tannophilus liquid medium: xylose 15, glucose 40, yeast powder 5, peptone, MgSO 4 0.2, CaCl 2 0.5, KH 2 PO 4 1.0, pH4.5;

[0087] b. Pachysolomyces tannophilus solid medium: xylose 15, glucose 40, yeast powder 5, peptone 3, MgSO 4 0.2, CaCl 2 0.5, KH 2 PO 4 1.0, agar 15, pH4.5;

[0088] c. Preparation of Saccharomyces cerevisiae liquid medium: glucose 40, yeast powder 5, peptone 3, MgSO 4 0.2, CaCl 2 0.5, KH 2 PO 4 1.0, pH4.5;

[0089] d. Preparation of Saccharomyces cerevisiae solid medium: glucose 40, yeast powder 5, peptone 3, MgSO 4 0.2, CaCl 2 0.5, KH 2 PO 4 1.0, agar 15, pH 4.5.

[0090] (2) Preparation of fermentation medium:...

Embodiment 2

[0111] The invention provides a method for improving the yield of ethanol produced by sugar beet fermentation, comprising the steps of:

[0112] I. Culture medium preparation

[0113] (1) Yeast culture medium preparation: the dimensions of the material proportion involved in this step are all g / L.

[0114] a. Preparation of Pachysolen tannophilus liquid medium: xylose 20, glucose 50, yeast powder 8, peptone 4, MgSO 4 0.3, CaCl 2 1.0, KH 2 PO 4 2.0, pH5.0;

[0115] b. Pachysolomyces tannophilus solid medium: xylose 20, glucose 50, yeast powder 8, peptone 4, MgSO 4 0.3, CaCl 2 1.0, KH 2 PO 4 2.0, agar 17, pH5.0;

[0116] c. Preparation of Saccharomyces cerevisiae liquid medium: glucose 50, yeast powder 8, peptone 4, MgSO 4 0.3, CaCl 2 1.0, KH 2 PO 4 2.0, pH5.0;

[0117] d. Preparation of Saccharomyces cerevisiae solid medium: glucose 50, yeast powder 8, peptone 4, MgSO 4 0.3, CaCl 2 1.0, KH 2 PO 4 2.0, agar 18, pH 5.0.

[0118] (2) Preparation of fermentation ...

Embodiment 3

[0140] The invention provides a method for improving the yield of ethanol produced by sugar beet fermentation, comprising the steps of:

[0141] I. Culture medium preparation

[0142] (1) Yeast culture medium preparation: the dimensions of the material proportion involved in this step are all g / L.

[0143] a. Preparation of Pachysolen tannophilus liquid medium: xylose 25, glucose 60, yeast powder 10, peptone 5, MgSO 4 0.4, CaCl 2 1.5, KH 2 PO 4 3.0, pH5.5;

[0144] b. Pachysolen tannophilus solid medium: xylose 25, glucose 60, yeast powder 10, peptone 5, MgSO 4 0.4, CaCl 2 1.5, KH 2 PO 4 3.0, agar 20, pH5.5;

[0145] c. Preparation of Saccharomyces cerevisiae liquid medium: glucose 60, yeast powder 10, peptone 5, MgSO 4 0.4, CaCl 2 1.5, KH 2 PO 4 3.0, pH5.5;

[0146] d. Preparation of Saccharomyces cerevisiae solid medium: glucose 60, yeast powder 10, peptone 5, MgSO 4 0.4, CaCl 2 1.5, KH 2 PO 4 3.0, agar 20, pH 5.5.

[0147] (2) Preparation of fermentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com