Multi-station automatic feeding method and device

An automatic feeding, multi-station technology, used in positioning devices, feeding devices, storage devices, etc., can solve the problems of inaccurate feeding positions, inability to use stamping parts, and high equipment costs, so as to achieve accurate and reliable feeding and reliable clamping. The effect of holding the workpiece and having good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

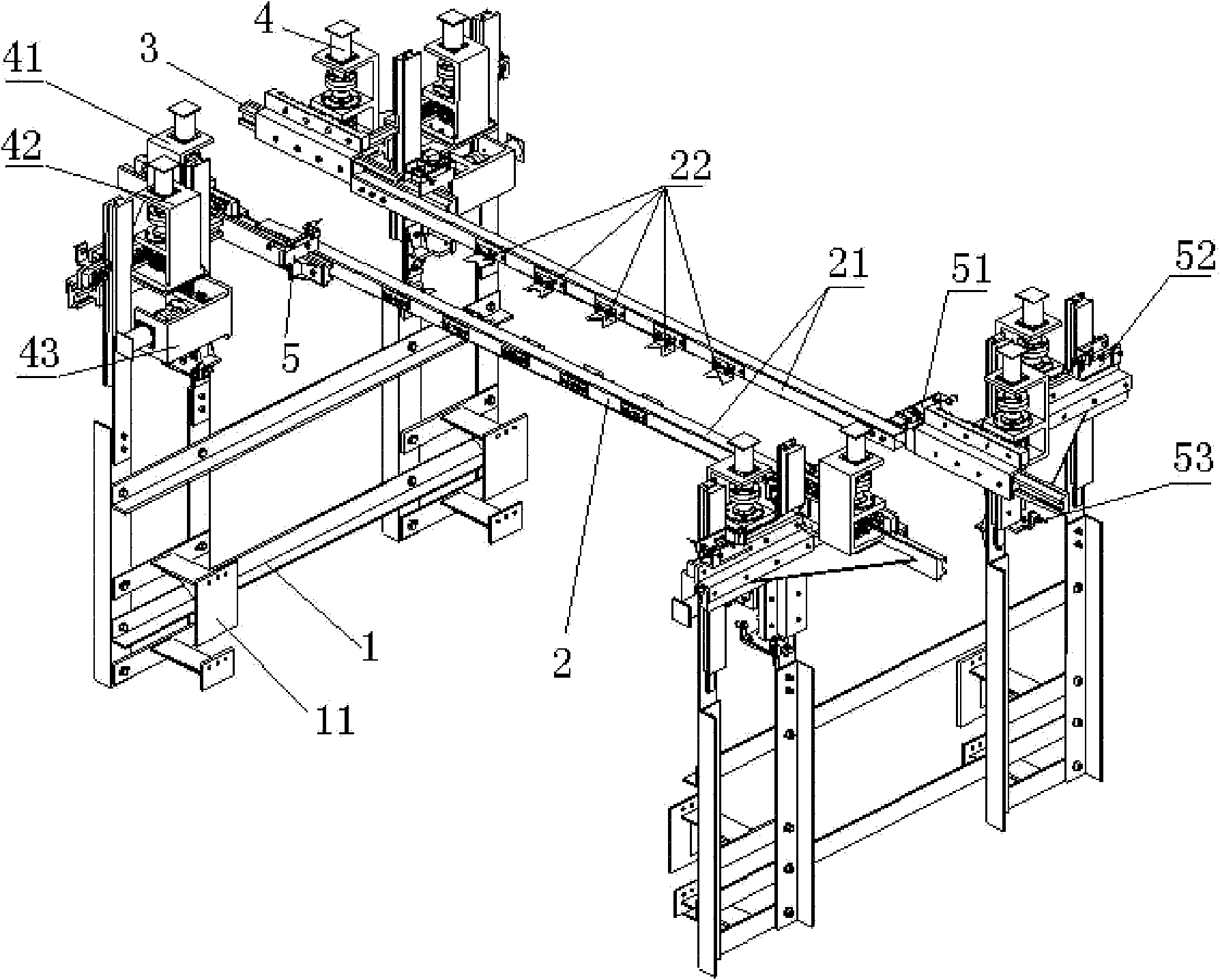

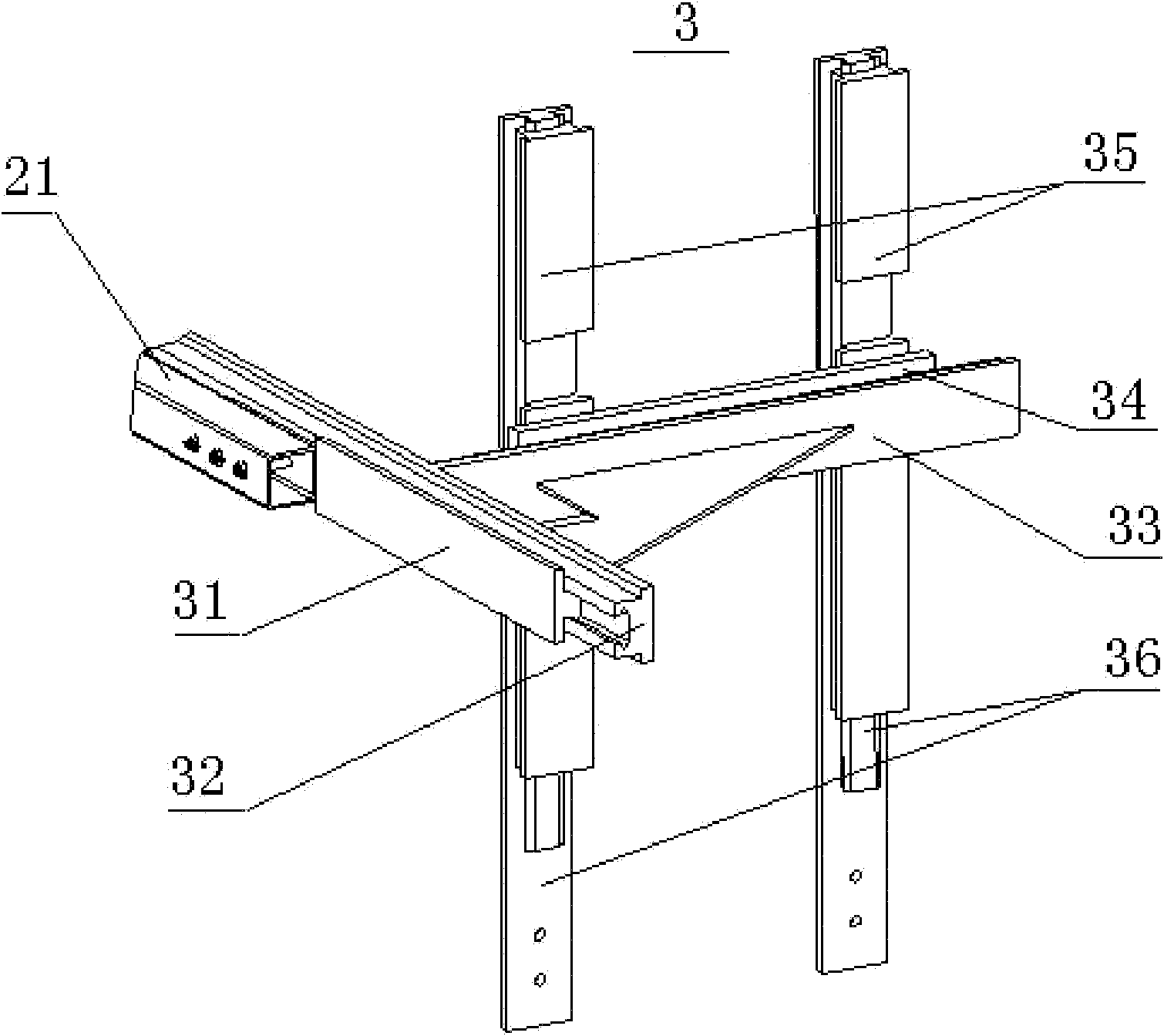

[0020] Such as figure 1 As shown, the present invention includes an actuator 2, a guide mechanism 3, a driving device 4, a sensing and limiting device 5 arranged on a frame 1, and a control system (not shown in the figure).

[0021] Frame 1 is used to connect and fix each part of the device of the present invention. Frame 1 is formed by welding and threaded connection of shaped steel and steel plate. On the press, it moves in coordination with the press, and the workpiece is continuously and automatically transferred between the multi-station molds on the press.

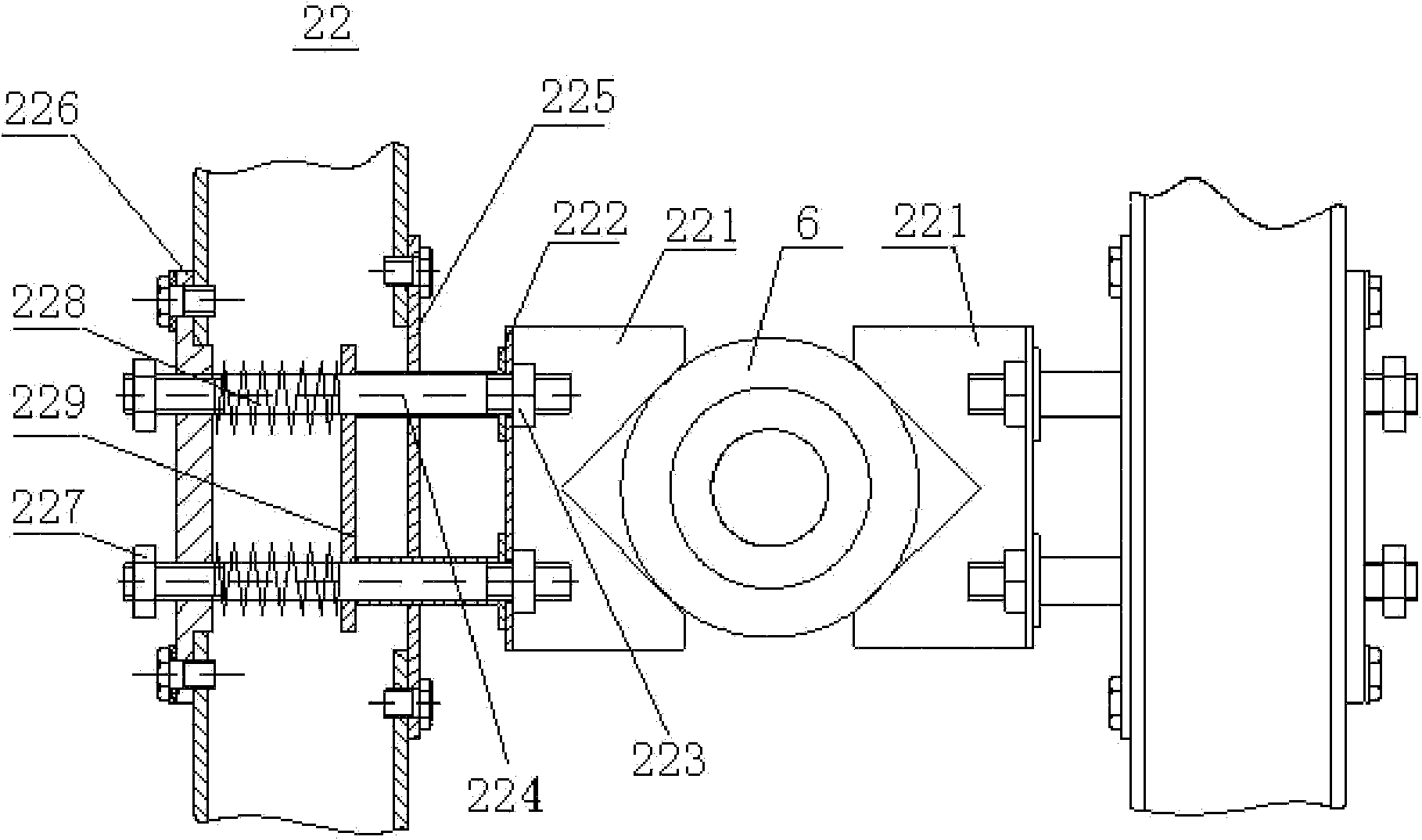

[0022] The actuator 2 includes two walking beams 21 arranged in parallel, and several pairs of clamping devices 22 are arranged at intervals on the two walking beams 21 . As the carrier of the feeding movement, the walking beam 21 is processed by square steel and arranged in parallel along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com