Sample cutter for preparing undisturbed loess sample for triaxial test

A technology of triaxial test and sample cutting instrument, which is applied in the field of equipment, can solve the problems of difficult cutting, increasing the axial torque of soil samples, local block falling, etc., and achieves the effect of high automation, high control precision and reduced disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

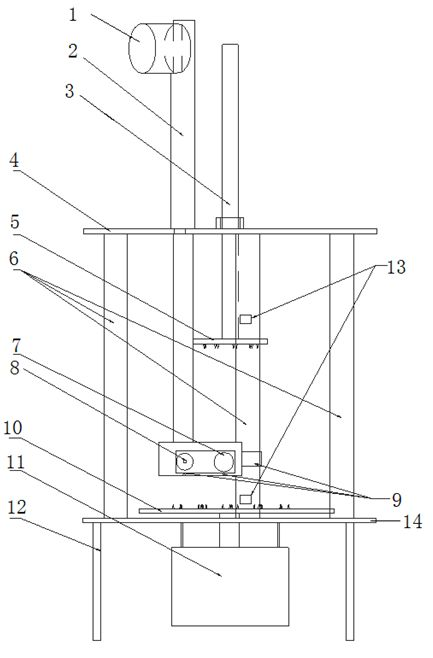

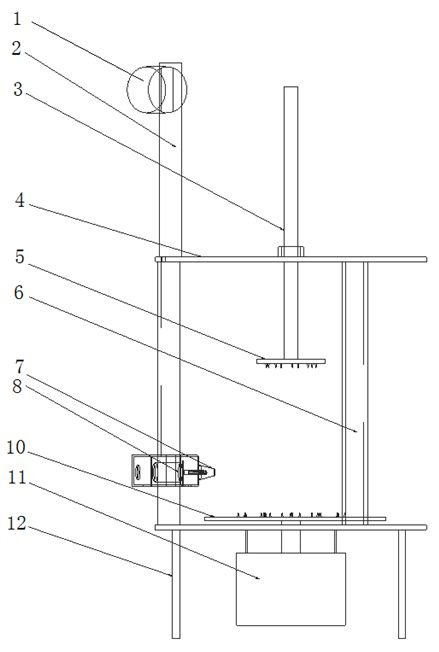

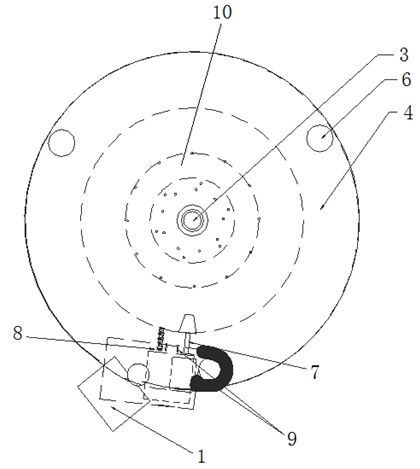

[0012] See attached figure 1 , the present invention is used to prepare the undisturbed loess sample cutting instrument of triaxial test, comprises support 12, and base plate 14 is arranged on support 12, and synchronous motor 11 is installed below base plate 14, and base plate 14 is provided with lower cut soil plate 10 , the lower cutting soil plate 10 is rotated by a synchronous motor 11; a support column 6 is distributed on the base plate 14, a top plate 4 is arranged on the support column 6, and a connecting shaft 3 is installed on the top plate 4, and the upper and lower cutting soil plates are arranged on the connecting shaft 3 10 corresponding upper cutting soil plate 5; There is also telescopic push rod 2 on the top plate 4, is provided with direct current motor 1 above telescopic push rod 2, and there is cutting soil knife rest 7 and below telescopic push rod 2 Linear motor 8, cutting soil knife rest 7 is equipped with cutting soil cutter, and linear motor 8 drives s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com