Ultrasonic impact treatment process for reducing residual stress of aluminium alloy box girder welded structure

A welding structure, ultrasonic impact technology, applied in the field of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

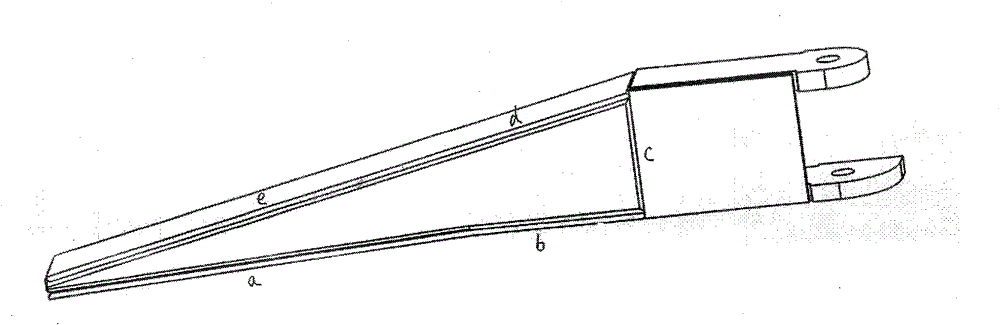

[0028] like figure 2 As shown, the 6mm thick aluminum alloy box girder welded structural support is subjected to ultrasonic impact treatment. It includes the following steps:

[0029] The first step: the selection of the impact head: according to the wall thickness of the aluminum alloy bracket is 6mm and the welding seam is a corner butt joint structure, so choose a double-row small impact head with a diameter of 4mm;

[0030] Step 2: Optimization of ultrasonic shock treatment process parameters: optimize the shock treatment process according to the wall thickness of the aluminum alloy bracket is 6mm, the impact speed is 1.3mm / min, the width is 10mm, the number of times is 4 times, and the impact angle is 90°;

[0031] The third step: impact treatment on the aluminum alloy box girder welded structure: use the optimized ultrasonic impact process to process the two long welds of the aluminum alloy bracket;

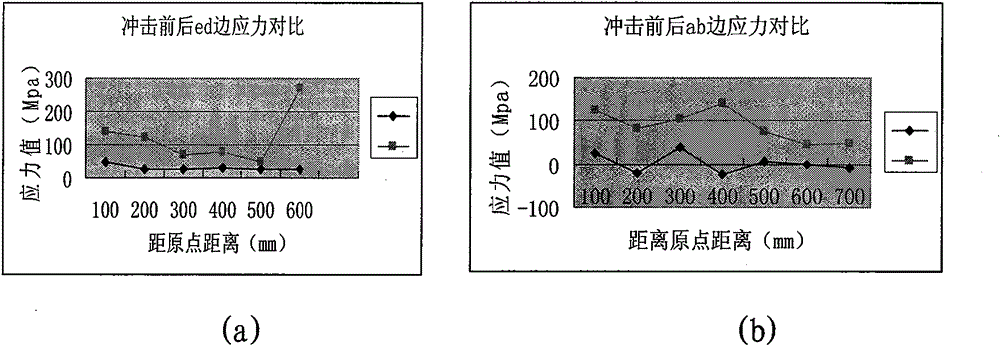

[0032] The fourth step: effect evaluation: by comparing the welding...

Embodiment 2

[0034] Ultrasonic impact treatment was performed on a 15 mm thick aluminum alloy rectangular beam. It includes the following steps:

[0035] The first step: the selection of the impact head: according to the thickness of the aluminum alloy rectangular beam is 15mm and the welding seam is a flat butt joint structure, so choose a double-row medium-sized impact head with a diameter of 6mm;

[0036] The second step: optimization of ultrasonic impact treatment process parameters: optimize the impact treatment process according to the wall thickness of the aluminum alloy rectangular beam of 15mm, the impact speed is 1.0mm / min, the width is 12mm, and the impact angle is 90°;

[0037] The third step: impact treatment on the aluminum alloy rectangular beam welded structure: use the optimized ultrasonic impact process to process the two long welds of the aluminum alloy rectangular beam;

[0038] Step 4: Effect evaluation: By comparing the welding residual stress state of the welding se...

Embodiment 3

[0040] Ultrasonic impact treatment is performed on the 25mm thick aluminum alloy box. It includes the following steps:

[0041] The first step: the selection of the impact head: according to the wall thickness of the aluminum alloy bracket is 25mm and the welding seam is a corner joint structure, so choose a single row of large impact head with a diameter of 8mm;

[0042] Step 2: Optimization of ultrasonic impact treatment process parameters: optimize the impact treatment process according to the wall thickness of the aluminum alloy box is 25mm, the impact speed is 0.8mm / min, the width is 14mm, and the impact angle is 80°~90°;

[0043] The third step: impact treatment on the welded structure of the aluminum alloy box: use the optimized ultrasonic impact process to treat the 12 long welds of the aluminum alloy box;

[0044] Step 4: Effect evaluation: By comparing the welding residual stress state of the welding seam of the aluminum alloy box welding structure that has undergone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com