Pre-processing process for spraying keyboard

A pretreatment and keyboard technology, applied in the direction of pretreatment surface, coating, surface coating liquid device, etc., can solve the problems of waste of human resources, dust adhesion, strong smell, etc., to save human resources and labor costs , Reduce workshop odor, fast volatilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

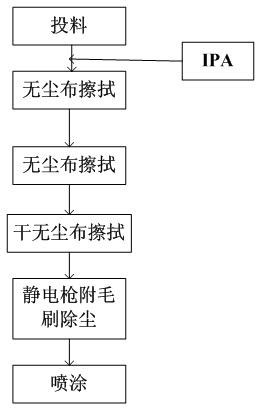

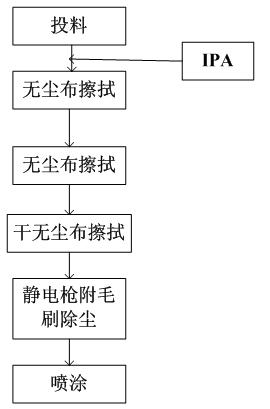

[0019] Such as figure 1 Shown, keyboard spraying pre-treatment process of the present invention comprises following dedusting steps:

[0020] Feeding: put the keyboard products to be processed into the spraying workshop;

[0021] Wipe with a dust-free cloth: Wipe the surface of the keyboard product with a dust-free cloth dipped in isopropyl alcohol (IPA for short); perform the dust-free cloth wiping step twice. IPA has a fast volatilization speed, low odor and good dust removal effect.

[0022] Wipe with a dry dust-free cloth: use a dry dust-free cloth to wipe the surface of the keyboard product;

[0023] Electrostatic gun dust removal: Use an electrostatic gun with a brush to stick to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com