Process for producing antiglare film

一种防眩膜、防眩层的技术,应用在对表面涂布液体的装置、辨认装置、纳米技术等方向,能够解决强膜表面、不均匀防眩膜、变白等问题,达到降低生产成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

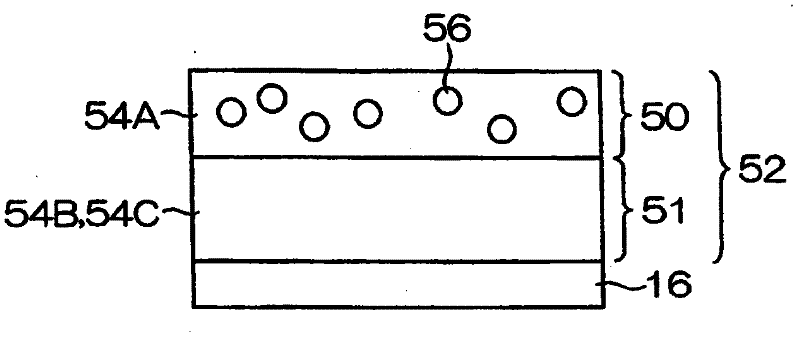

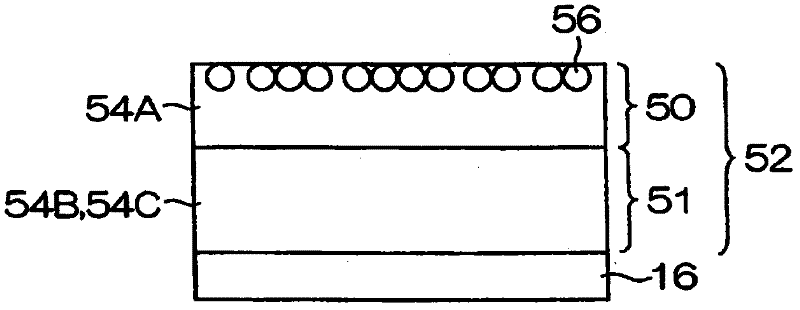

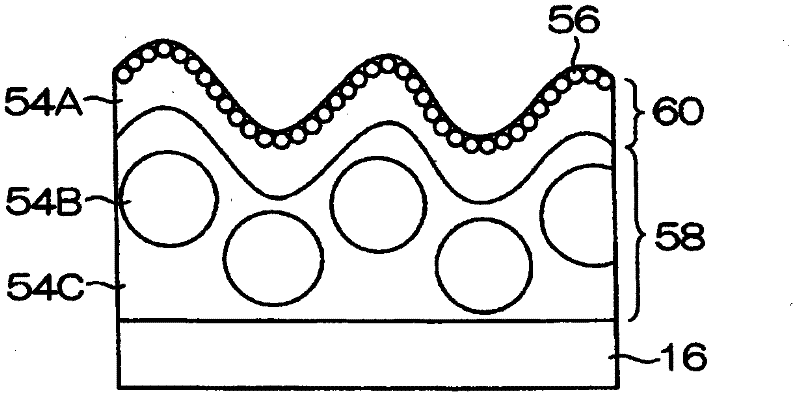

[0067] Figures 1A-1C is an explanatory diagram illustrating one example of the first embodiment of the production method of the antiglare film, and figure 2 is a schematic diagram illustrating one example of a production apparatus of an antiglare film. In this embodiment, description will be made by using an example of a coating liquid containing two kinds of resins A and B, however the case of two or more resins also has the same basic concept.

[0068] (Coating liquid preparation step)

[0069] The production method of the antiglare film according to the present invention firstly includes preparing a coating solution for forming an antiglare layer in which two mutually incompatible resins A and B are dissolved in a solvent and a low-refractive coating liquid in which the resin and particles are dissolved in a solvent. Coating solution for layer formation.

[0070] As the particle and resin material, those described later can be used. The mixing method is not particular...

no. 2 approach

[0164] Next, a second embodiment according to the present invention will be described.

[0165] Figure 5A and 5B is an explanatory diagram illustrating one example of a method of producing an antiglare film. Explanatory diagram of the preparation equipment for the anti-glare film ( figure 2 ) and the explanatory diagram of the coating device ( image 3 ) are the same as those used in the first embodiment.

[0166] In this embodiment, description is made using an example of a coating liquid comprising a first polymer whose substituent has a molecular structure that lowers the refractive index of the entire polymer and three types of resins A, B and C, the substituents of these three types of resins do not contain a molecular structure that lowers the refractive index of the entire polymer, but the case of three or more resins whose substituents do not contain a molecular structure that lowers the refractive index of the entire polymer is also the case. have the same basi...

Embodiment 1

[0210] (upper layer, low refractive index layer)

[0211] The surface of the hollow silica particles having an average particle diameter of 20 nm was treated with 3,3,3-trifluoropropylmethyldichlorosilane to hydrophobize the surface of the particle. A coating liquid was prepared by dissolving the composition shown below in 82 parts by mass of methyl ethyl ketone. The critical solid concentration of this system is 71%.

[0212] 15 parts by mass of acrylic resin

[0213] ●Hydrophobic particles 0.2 parts by mass

[0214] (lower layer, anti-glare layer)

[0215] A coating liquid was prepared by dissolving the composition shown below in 82 parts by mass of methyl ethyl ketone. The critical solid concentration of this system is 71%.

[0216] 2 parts by mass of cellulose acetate propionate

[0217] 15 parts by mass of acrylic resin

[0218] These liquids were applied on triacetyl cellulose (Fujitac, manufactured by Fujifilm Corp.) with a thickness of 80 μm by simultaneous mult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com