Double-cylinder plunger pump

A cylinder column and piston pump technology, which is applied in the field of hydraulic drive devices, can solve the problems of low flow rate of axial piston pumps, and achieve the effects of solving small flow rate, improving work efficiency and increasing flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

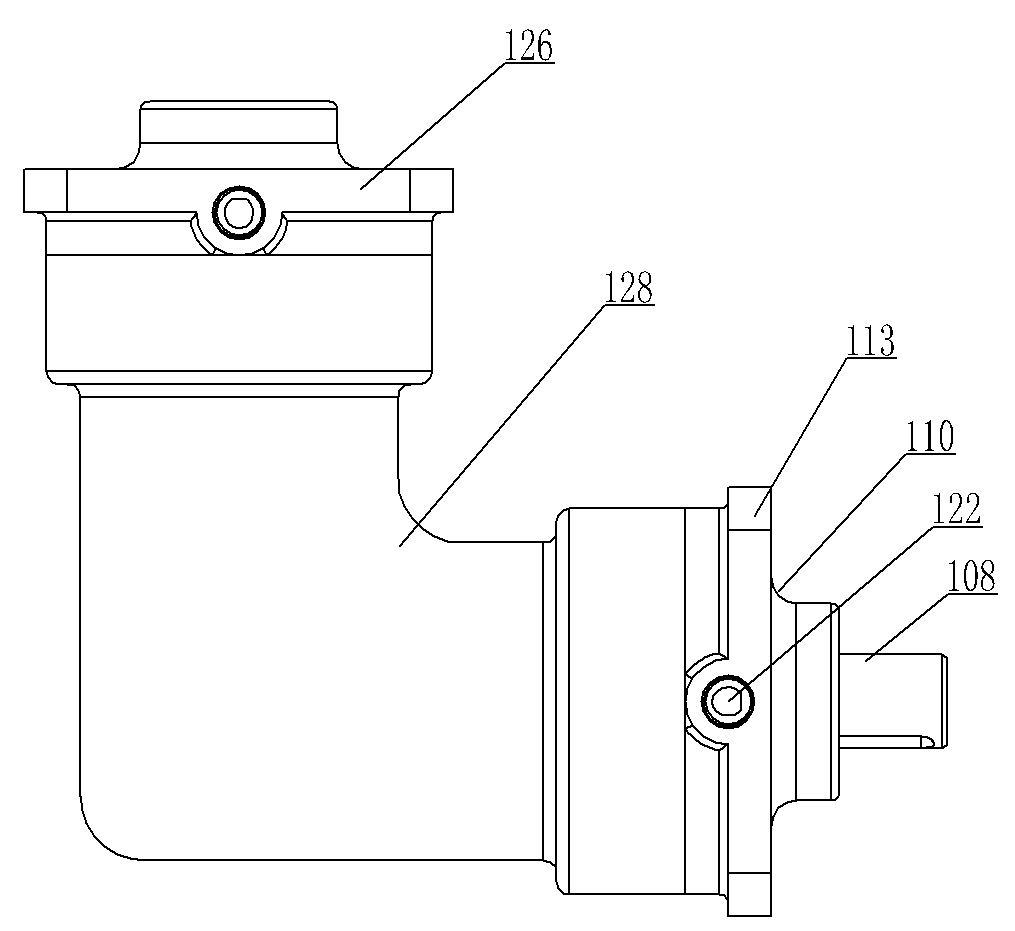

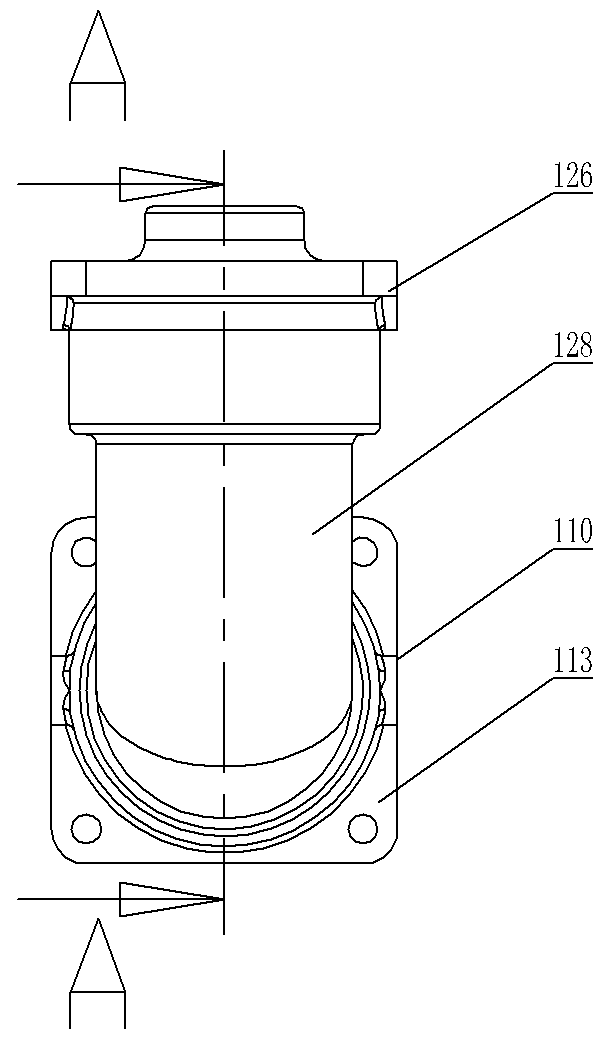

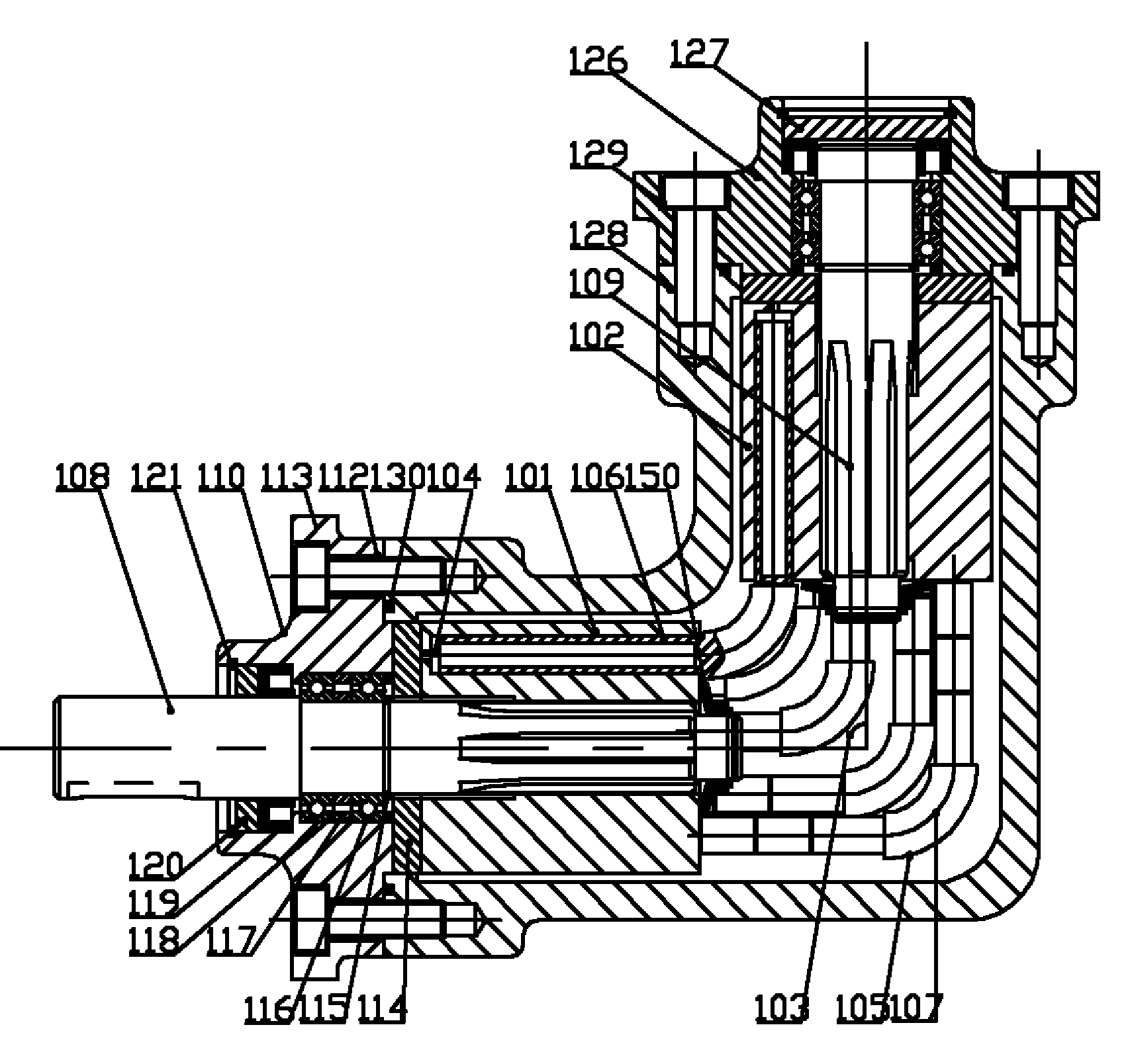

[0041] Embodiment 1 of the double cylinder plunger pump of the present invention, as Figure 1-16 As shown, there is a first cylinder 101 and a second cylinder 102, the axis of the first cylinder 101 and the axis of the second cylinder 102 intersect outside the first and second cylinders and form a first angle 103 ( See image 3), the first included angle is 90 degrees; the axes of the first and second cylinders are the sides of the first included angle 103, and the two axes define a plane, that is, the two axes are on the same plane , the plane is the first plane; the first cylinder 101 and the second cylinder 102 have the same structure and are commercially available; the first cylinder 101 is evenly distributed along the circumferential direction with first cylinder holes 104, the first The cylinder bore 104 extends along the axial direction of the first cylinder block 101, and the second cylinder block 102 has a second cylinder bore corresponding to the first cylinder bor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com