Large-aperture compressed natural gas storage well and installation method thereof

A technology for compressing natural gas and gas storage wells, which can be used in container filling methods, fixed-capacity gas storage tanks, and container discharge methods. The well pipe climbs or sinks, the overall cost advantage is significant, and the effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

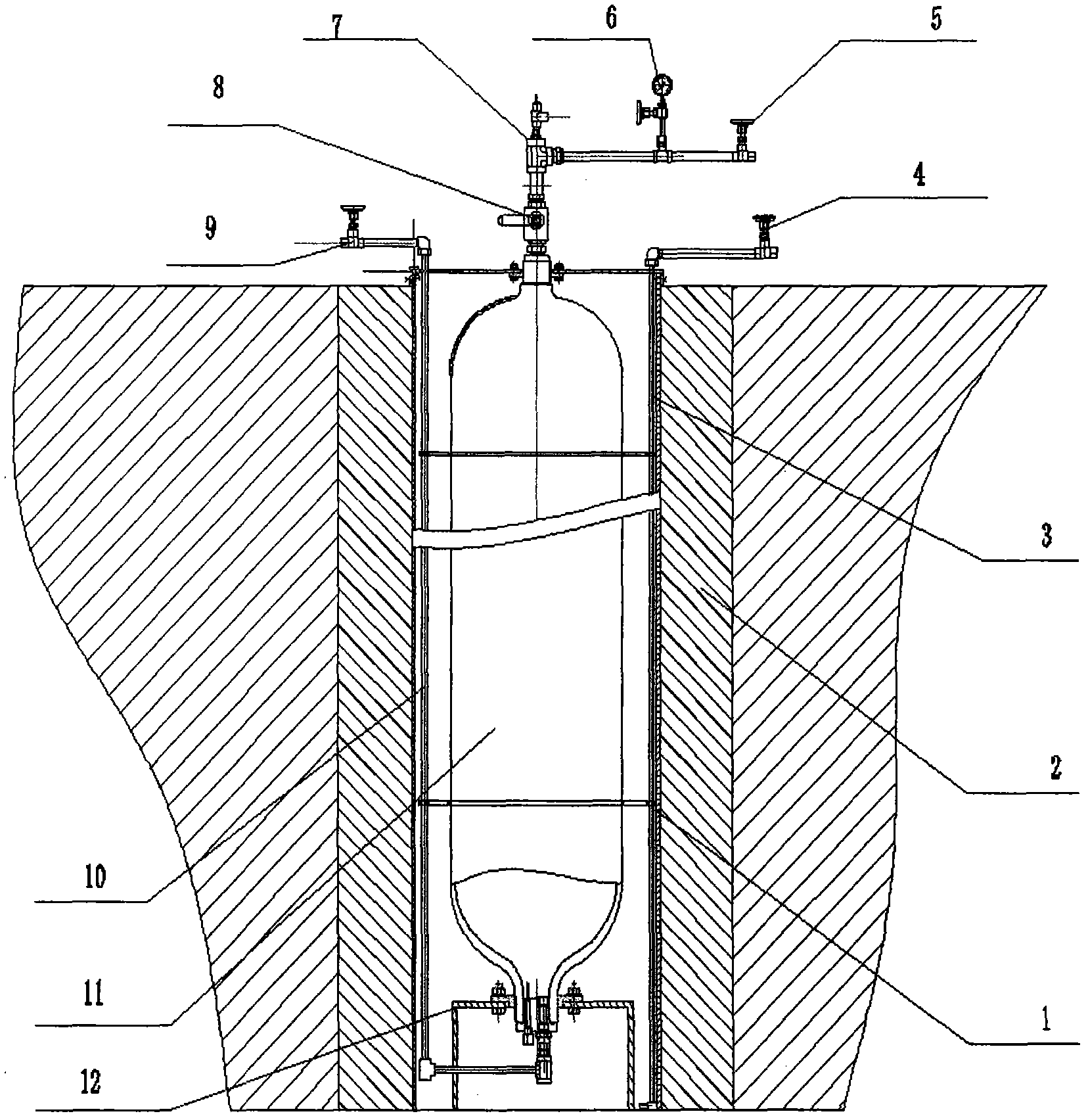

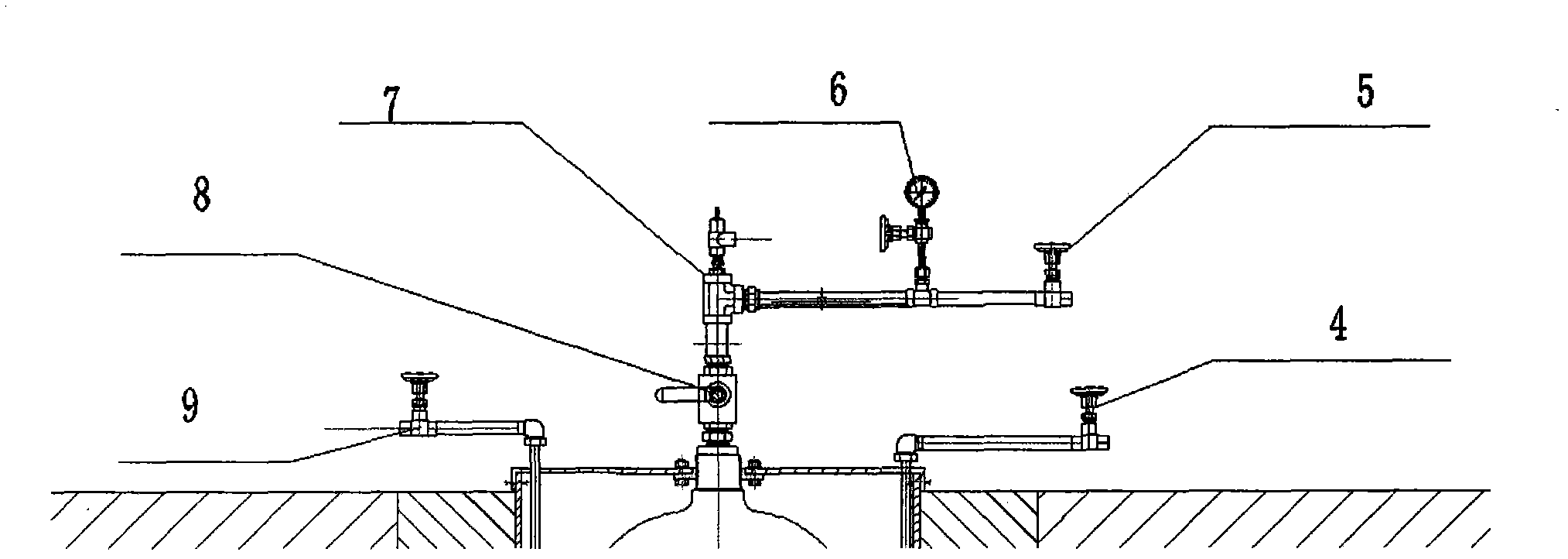

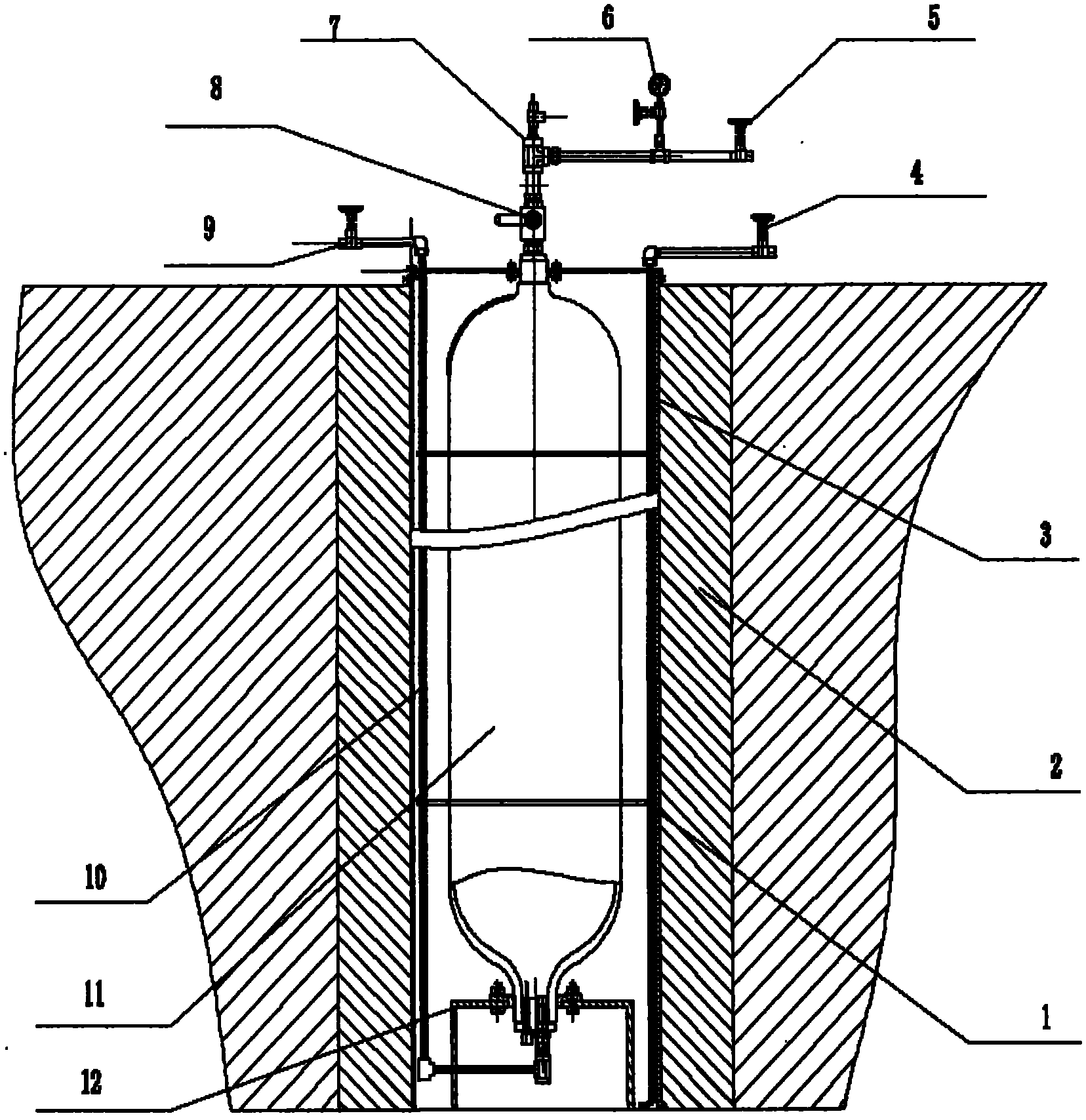

[0025] Gas storage well of the present invention (as figure 1 ) is a cylinder-type CNG gas storage well, which is a container buried underground for storing compressed natural gas. The bottle-type gas storage well of the present invention includes a cementing cast pipe 1, a cementing cement layer 2, a drying pipeline 3, a drying pipeline valve 4, a gas inlet and outlet pipeline valve 5, a pressure gauge 6, a safety valve 7, a main control valve 8, Sewage pipeline 9, sewage pipeline 10, gas cylinder 11, fixed position 12 (as figure 2 ); the lower end of the gas storage cylinder 11 is installed on the bottom supporting flange, and the upper part of the gas storage cylinder 11 is fixed on the sealing flange of the gas storage cylinder mouth with flanges and pins, and the cementing cast pipe 1 and the gas storage cylinder neck flange Form a closed structure; the space between the gas storage cylinder and the cementing cast pipe is installed with a drying pipeline (3), and the up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com