Throwing hole orientator of bit hole rig and positioning method

A technology of roller cone drilling rig and locator, which is applied to earth-moving drilling, surveying, wellbore/well components, etc., can solve the problems of the roller cone drilling rig having no positioning function, laborious positioning, and time-consuming positioning, etc., and achieves simple structure and convenient use. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

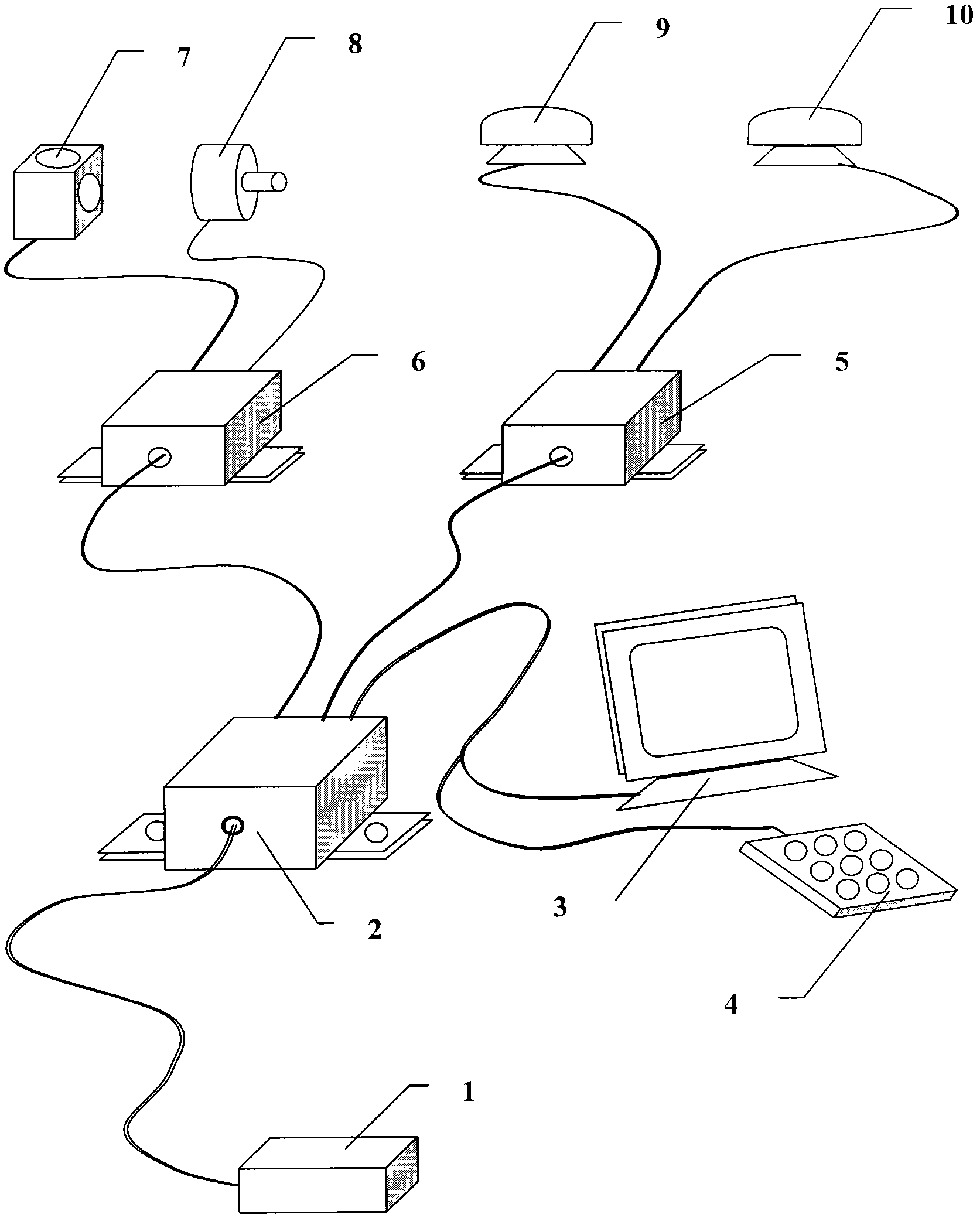

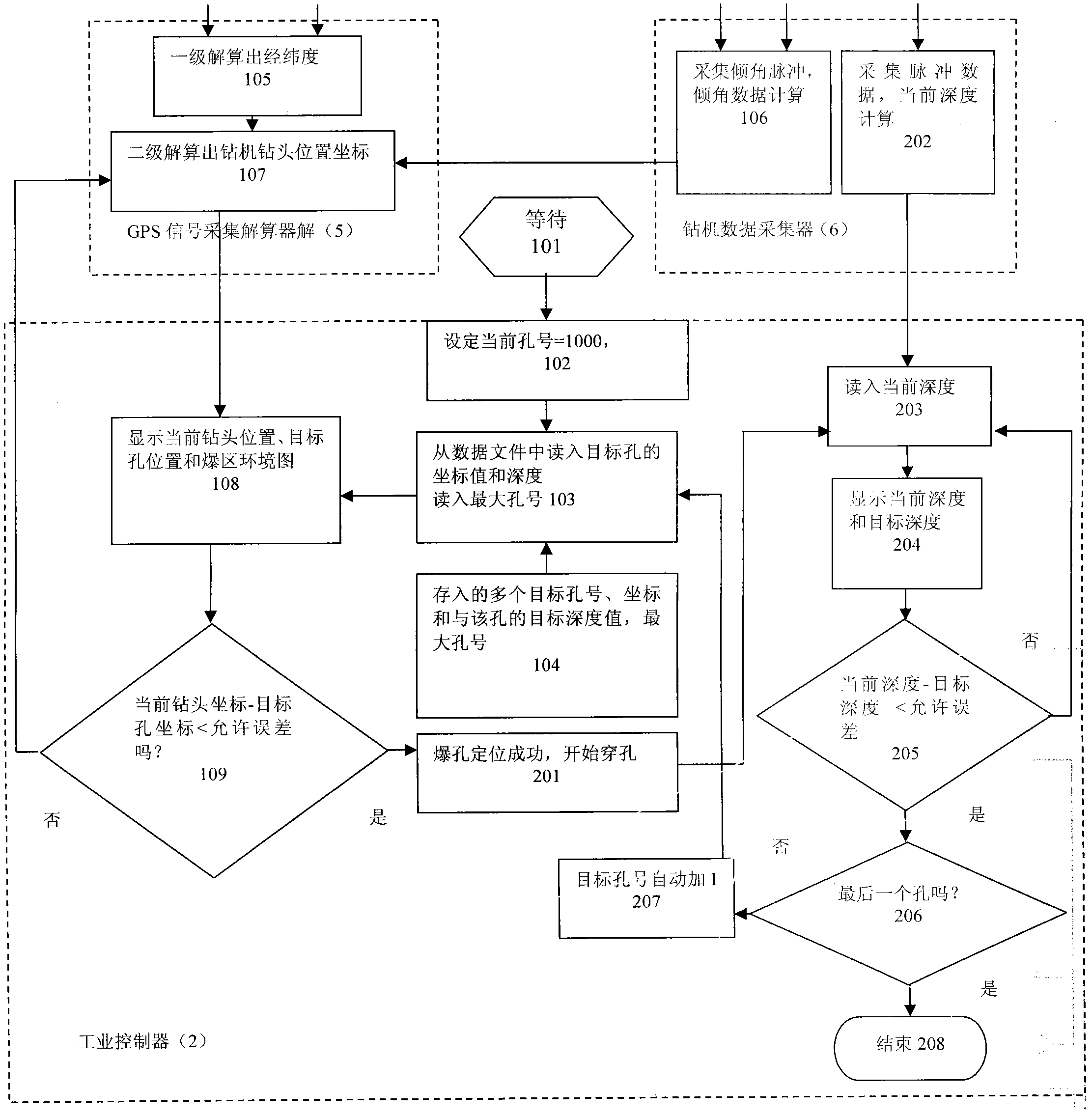

[0062] Such as figure 1 As shown, the roller drill throwing hole locator includes:

[0063] Two GPS antennas (9 and 10) are used to perceive the position of the drilling rig, and convert the received position information of the drilling rig into electrical signals and transmit them to the signal acquisition solver;

[0064] The signal acquisition solver 5 is used for real-time acquisition and buffering of the electrical signals from the two GPS antennas, and the electrical signals are resolved into the position coordinates of the centers of the two GPS antennas and sent to the controller;

[0065] Dual inclination sensors 7 are used to sense the inclination angle of the drilling rig, generate pulses related to the inclination angle, and transmit the inclination angle pulse data to the data collector;

[0066] The data collector 6 is used for collecting and buffering the inclination pulse data from the dual inclination sensors in real time, and transmitting the inclination pul...

Embodiment 2

[0093] Roller drill throw hole locators include:

[0094] Two GPS antennas 9 and 10 are used to sense the position of the drilling rig, convert the received position information of the drilling rig into electrical signals and send them to the signal acquisition solver;

[0095] Dual inclination sensors 7 are used to sense the inclination angle of the drilling rig, generate pulses related to the inclination angle, and transmit the inclination angle pulse data to the signal acquisition solver;

[0096] The signal acquisition solver 5 is used to collect and buffer the electrical signals from two GPS antennas in real time, and the inclination pulse data from the dual inclination sensors, and resolve the electrical signals and the inclination pulse data into drill bits. The position coordinates are transmitted to the controller;

[0097] The controller 2 is used to receive the drill bit position coordinates sent by the signal acquisition solver in real time, compare the drill bit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com