Jet rotor

A technology of rotors and internals, which is applied in the field of injection rotors, can solve the problems of cumbersome installation and adjustment of axial clearance, high cost of turbine blade processing, scrapping of exhaust gas turbochargers, etc., and achieves the advantages of light weight, high cost performance and small fluid energy loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

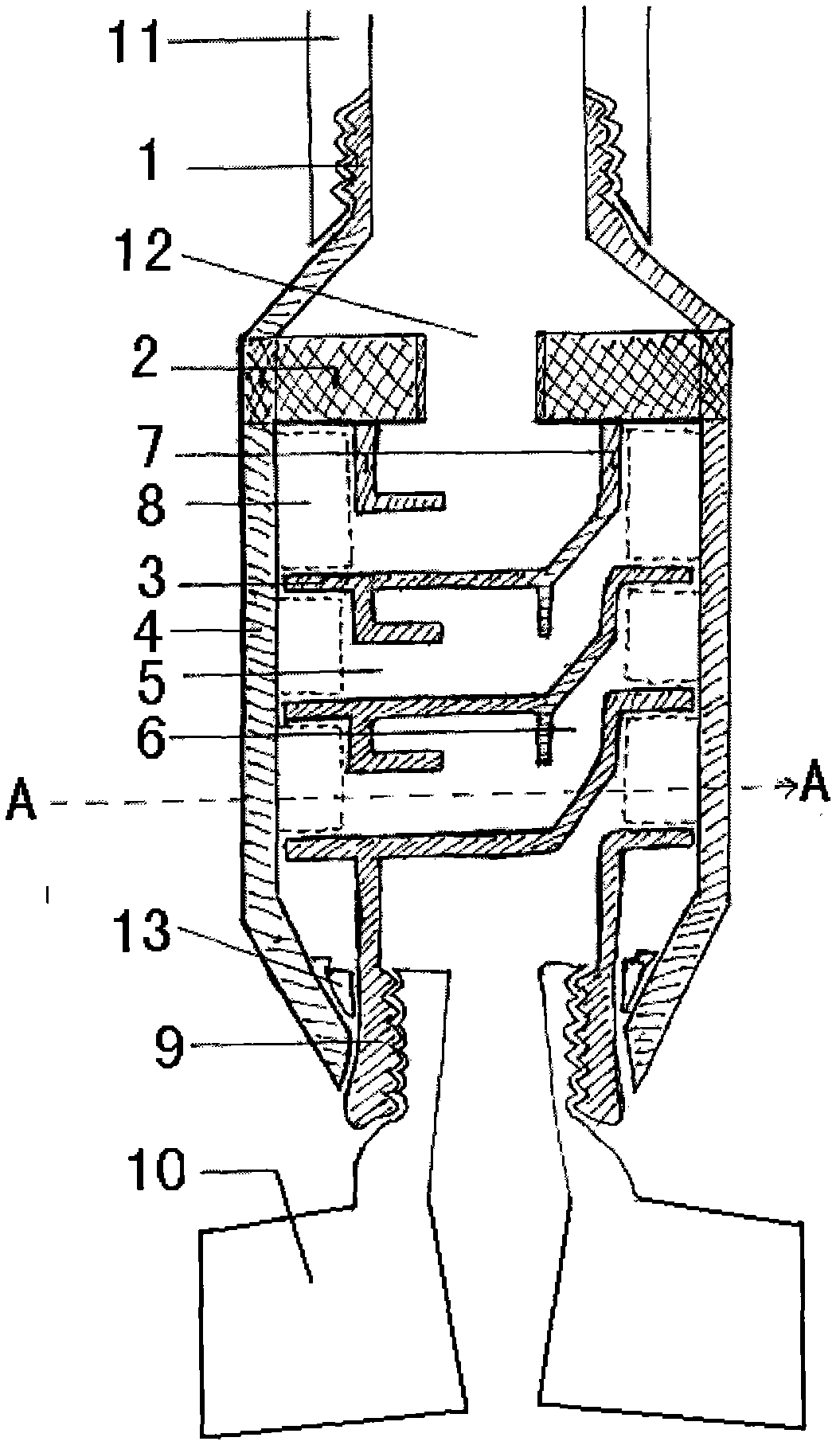

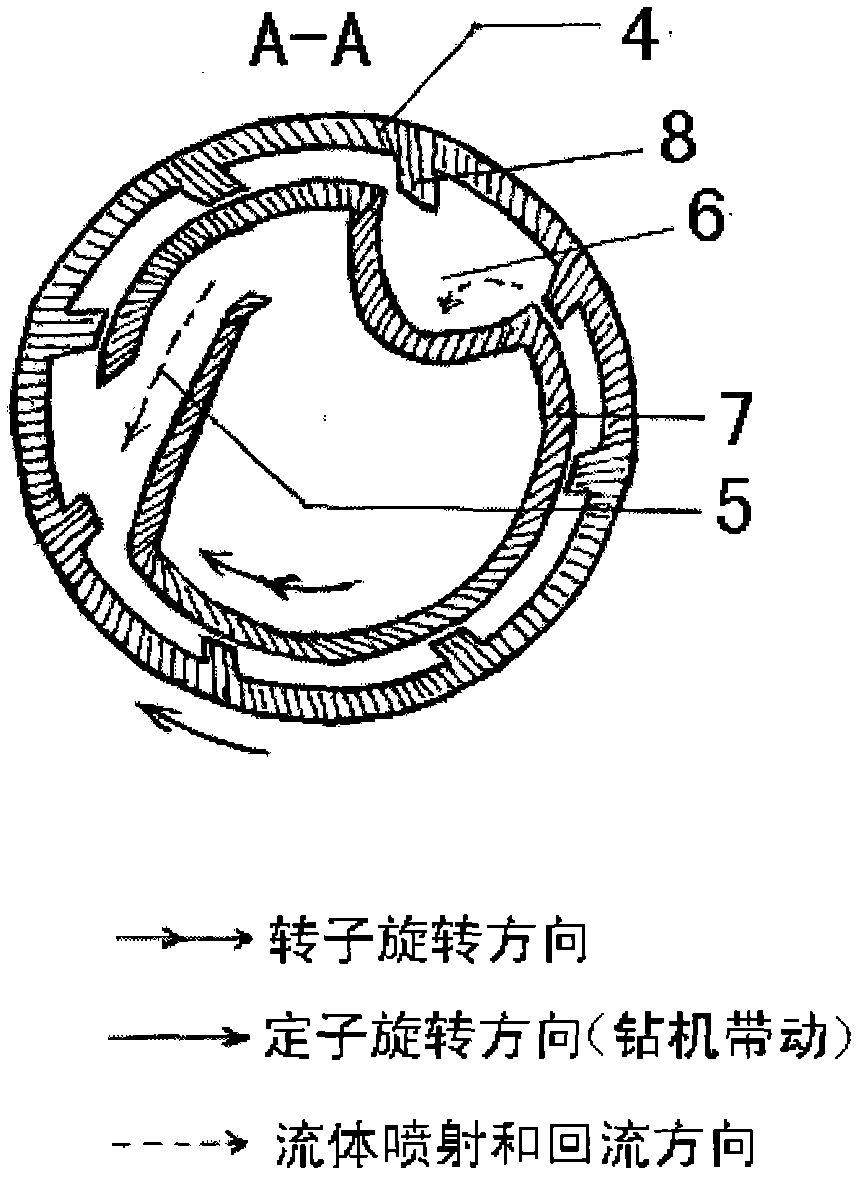

[0031] Embodiment 1: inner rotor type downhole power drilling tool with jet rotor: (as attached figure 1 , 2 As shown) the injection rotor is connected with the upper connection structure 1, the bearing assembly 2 and the lower connection structure 9 to form this kind of downhole dynamic drilling tool, wherein the injection rotor is mainly composed of the inflow channel 12 and the outer body 4 (in this embodiment, the outer body is The main part of the stator), the inner son 7 (the inner son is the main part of the rotor in this embodiment), the nozzle 5, the radial partition 3, the fluid return pipe 6 and the thrust wall 8. Outer part 4 and inner part 7 are both round tubular in shape and have a common longitudinal axis center line, outer part 4 is set outside inner part 7, and outer diameter of outer part is the maximum diameter of this kind of downhole power drilling tool, and it is smaller than borehole The diameter of each inner sub 7 has at least one nozzle pipe 5, a r...

Embodiment 2

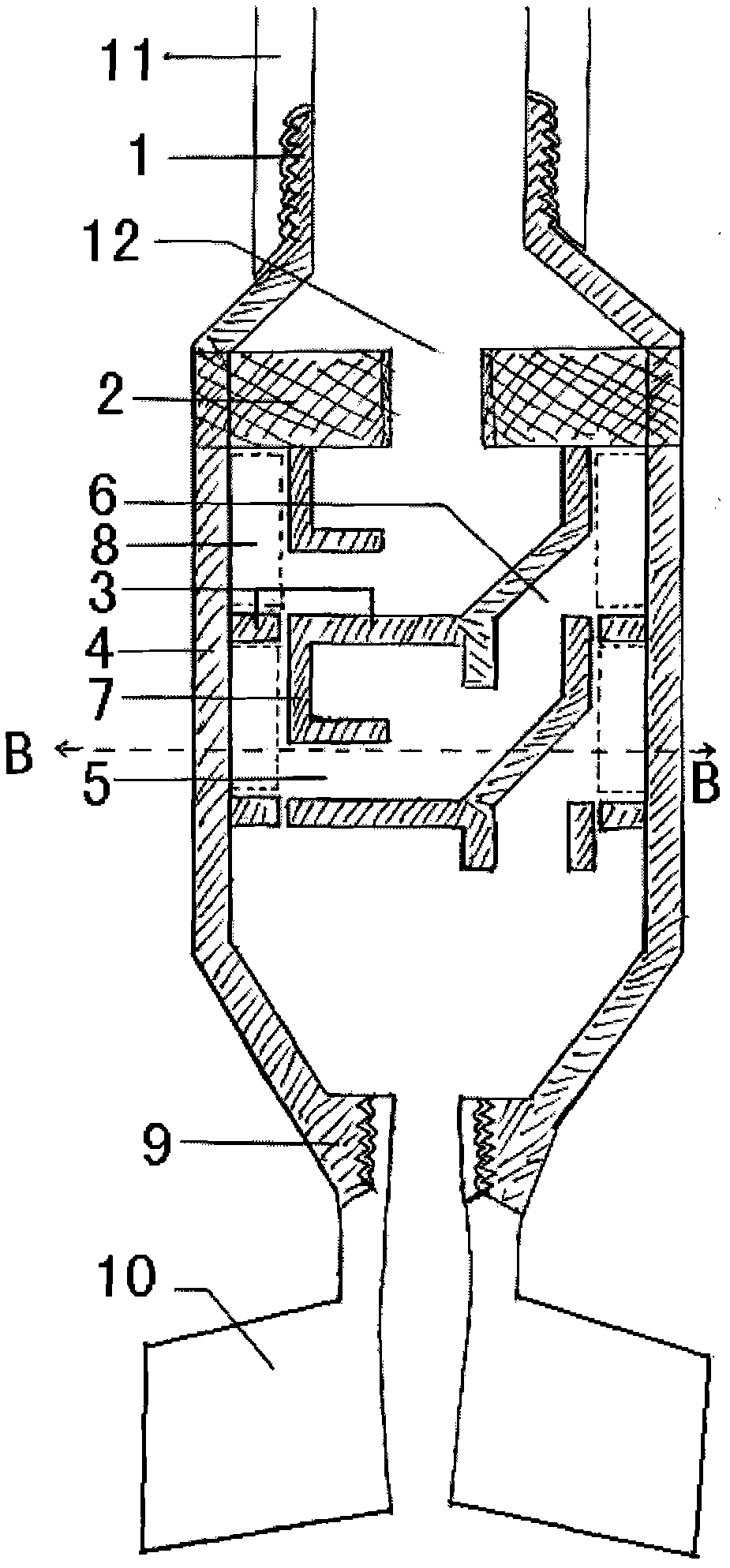

[0032] Embodiment 2: the outer rotor type downhole power drilling tool that has jet rotor: (as attached image 3 , 4 Shown) is similar to embodiment 1, the injection rotor is connected with the upper connection structure 1, the bearing assembly 2 and the lower connection structure 9 etc. In this embodiment, the outer son is the main part of the rotor), the inner son 7 (the inner son is the main part of the stator in this embodiment), the nozzle 5, the fluid return pipe 6, the radial partition 3 and the thrust wall 8. The inner part 7, that is, the stator, has at least one spray pipe 5, a radial partition 3, and a fluid return pipe 6 that penetrate the entire layer of the stator side wall along the circumferential tangential direction; the lower connection structure 9 is a part of the outer part 4, that is, the lower section of the rotor. 4. The lower section is connected downwards with the drill bit 10; the nozzle pipe 5, the radial partition 3, and the fluid return pipe 6 are...

Embodiment 3

[0034]Embodiment 3: " turbine " jet type core machine (inner rotor type) that has injection rotor: " turbine " jet type core machine that has injection rotor of the present invention is mainly by high-pressure air compressor 14, combustion chamber 15 and driving high pressure The compressor consists of at least one injection rotor, wherein the injection rotor is mainly composed of an inflow channel 12 , an outer part 4 , an inner part 7 , a plurality of nozzle pipes 5 and a plurality of thrust walls 8 . The inflow channel 12 introduces the high-temperature and high-pressure gas generated in the upstream combustion chamber 15 into the interior of the inner son 7 along the longitudinal axis of the inner son 7; the outer son 4 and the inner son 7 have a common central longitudinal axis, and the outer son 4 is sleeved on the inner son 7 outside and can rotate relatively along the common central longitudinal axis; there are multiple converging nozzles arranged tangentially along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com