Drive train arrangement for a vehicle

A technology for driving transmission and vehicles, which is applied to vehicle components, control devices, transportation and packaging, etc., to achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

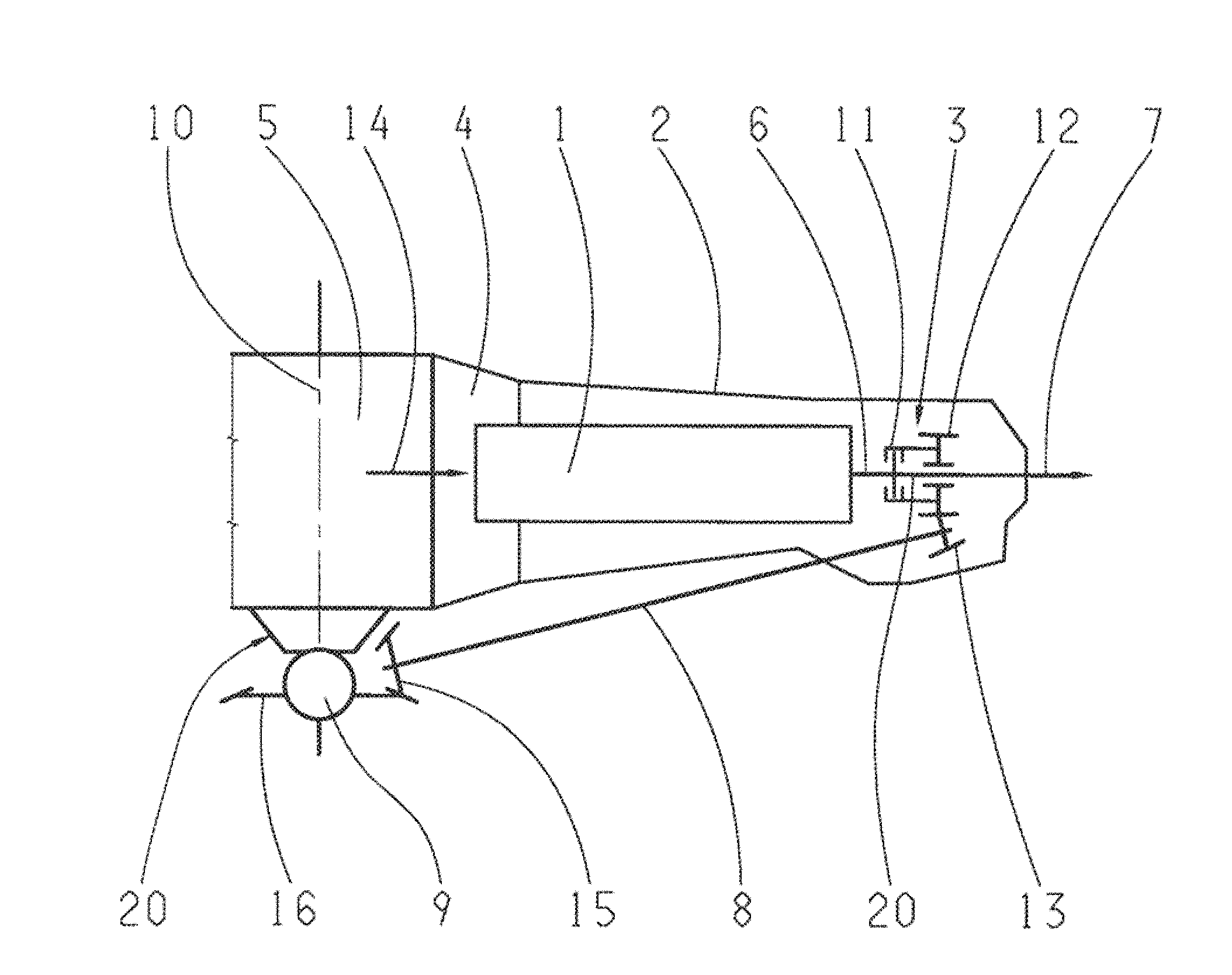

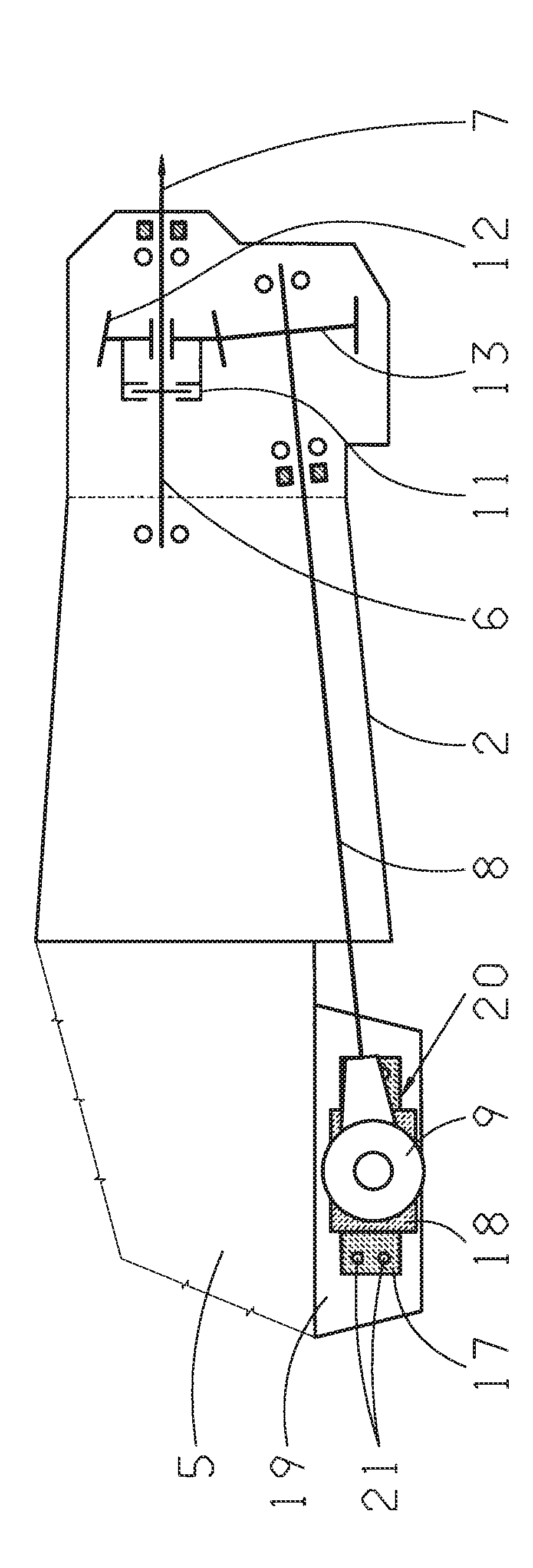

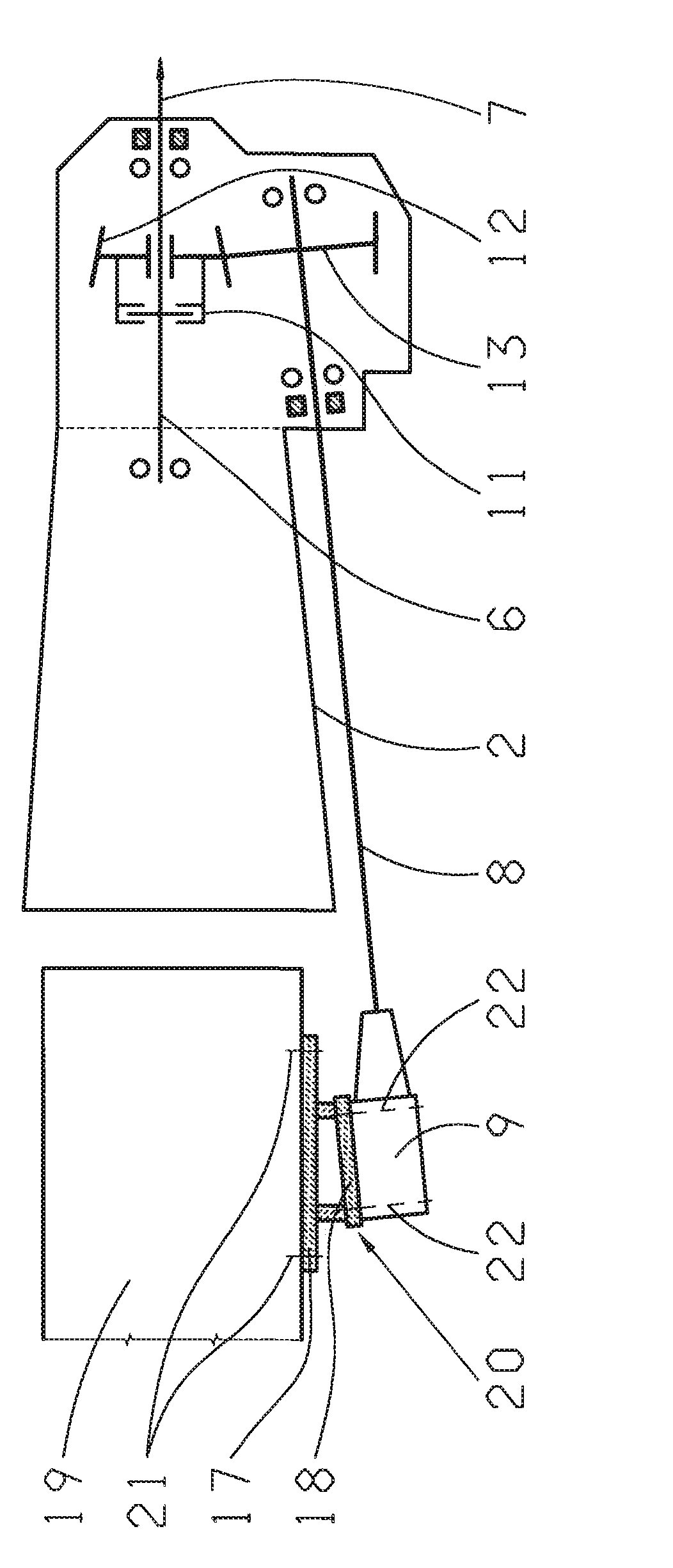

[0023] A possible embodiment of the drive train for a vehicle according to the invention is shown by way of example in the drawing, which has a main transmission 1 in which a transfer case 3 is integrated in a transmission housing 2 . In the drive train according to the invention, for example, an adjustable all-wheel drive can be provided, but also a purely rear-axle drive or a front-axle drive.

[0024] exist figure 1 shows an example of an adjustable all-wheel drive in a vehicle as a drive train. The drive train comprises the main transmission 1 , which is coupled via a starting element 4 with a drive motor 5 for torque transmission. The output shaft 6 of the main transmission 1 is connected to a shaft of the transfer case 3 . The output side of the transfer case 3 is permanently connected to a rear axle differential, indicated only schematically by arrow 7 . Furthermore, the output side of the transfer case 3 can also be selectively coupled via a torque transmission elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com