Magnetic coupling controlling means

A control device and magnetic coupling technology, which is applied in the direction of electromechanical devices, magnetic drive clutches, and single motor speed/torque control, can solve the problems of compact processing devices, reduced drive efficiency, and increased volume of magnetic motors, so as to increase the speed Accuracy, improved controllability, and the effect of preventing out-of-step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

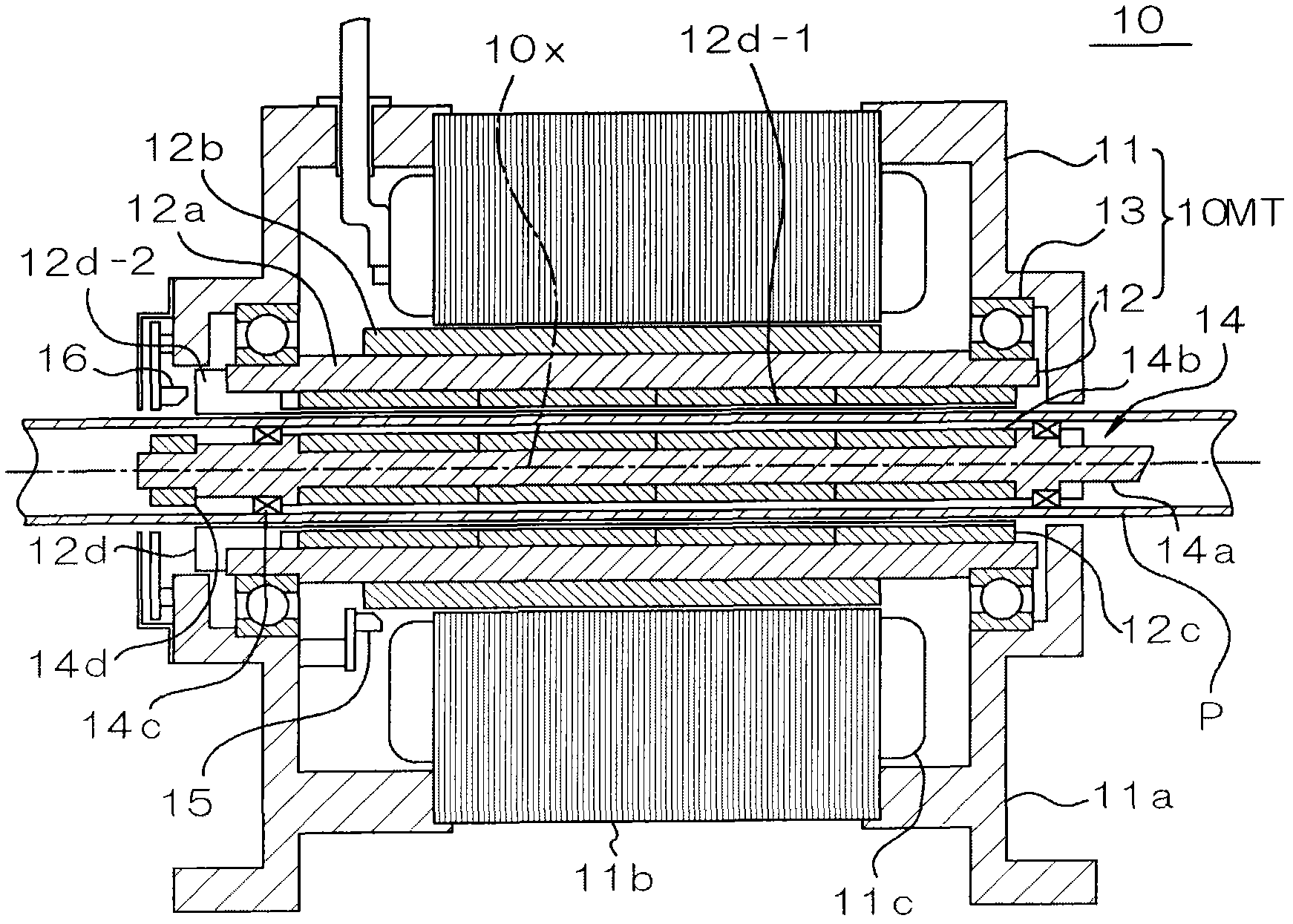

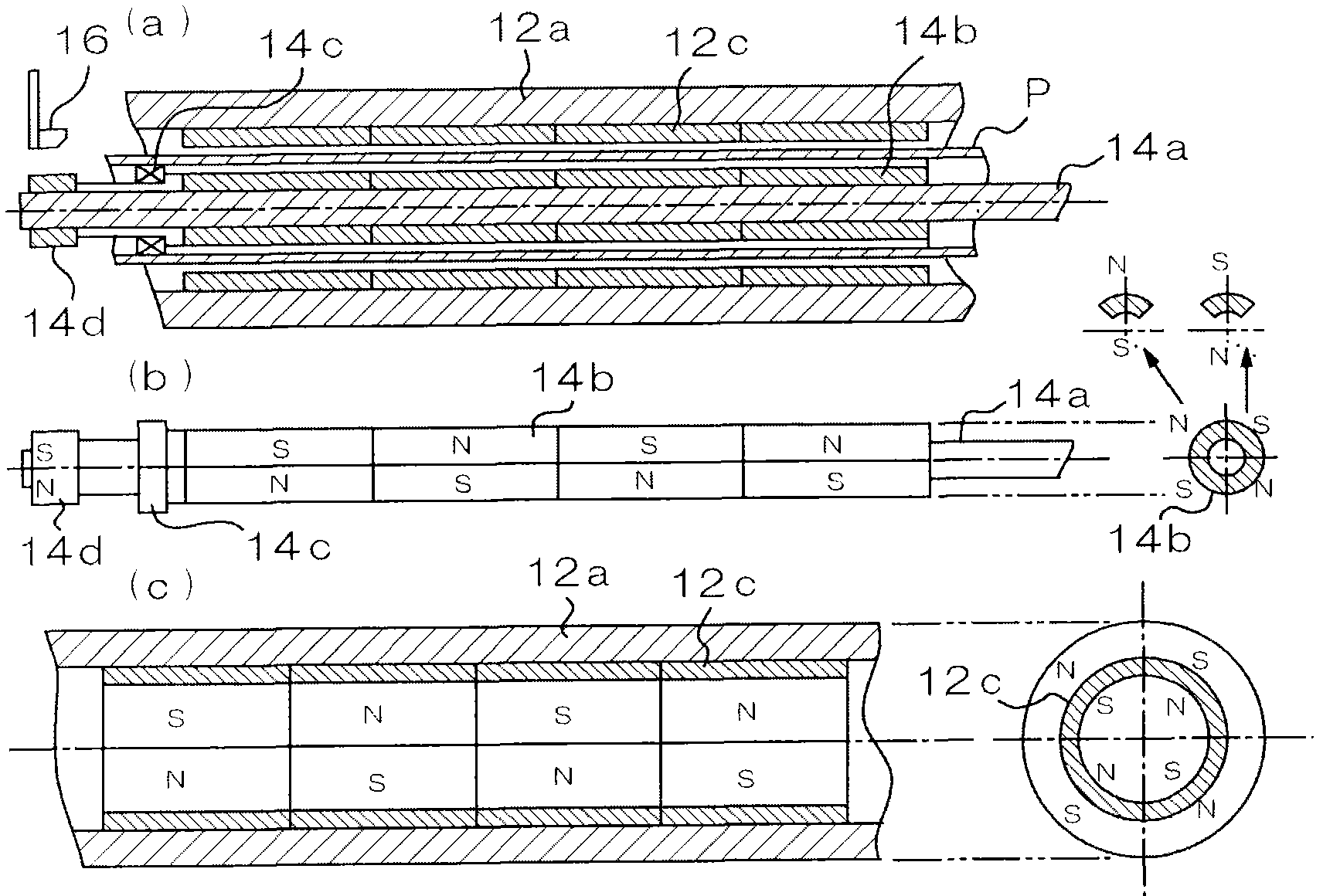

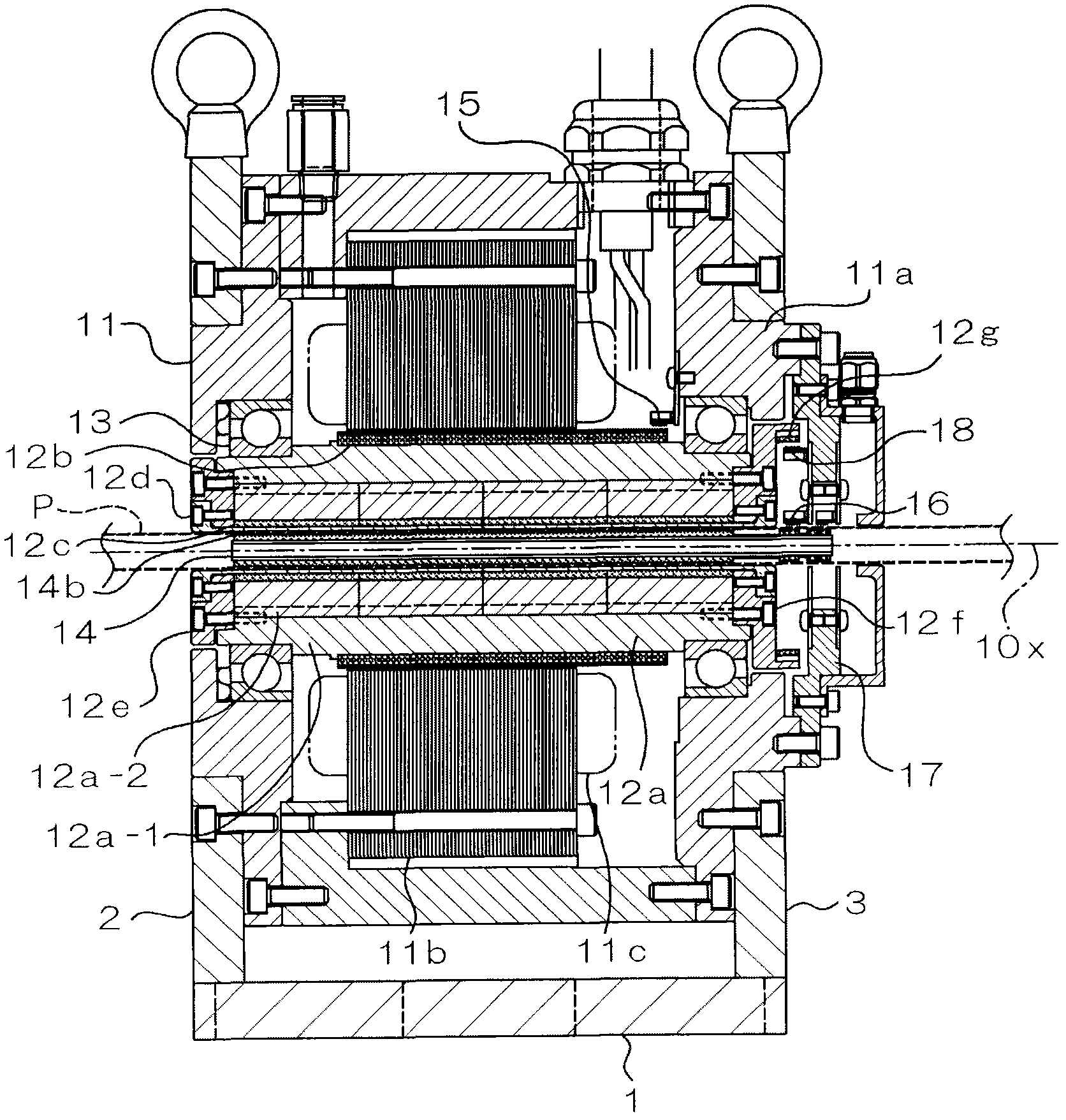

[0027] Next, embodiments of the magnetic coupling control device of the present invention will be described in detail with reference to the drawings. figure 1 It is a schematic longitudinal sectional view showing the basic structure of the embodiment, figure 2 It is partial figure (a)-(c) which shows each part of embodiment.

[0028] In the present embodiment, the magnetic coupling control device 10 includes an outer functional body 10MT having a stator portion 11 disposed on the outer periphery; and a rotor portion 12 disposed opposite to the inner side of the stator portion 11 . The outer functional body 10MT constitutes a DC brushless motor in the illustrated example. The stator unit 11 has a frame 11a opening (through) around the axis 10x and a plurality of stator poles 11b and coils 11c fixed inside the frame 11a and arranged around the axis 10x.

[0029] In addition, the rotor unit 12 has: a cylindrical magnetic cylinder (yoke) 12a rotatably supported by the frame 11a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com