Method and device for testing axial rigidity and radial rigidity of rotary hydrostatic guide rail

A technology of static pressure guide rail and axial stiffness, which is applied to the test of axial stiffness and radial stiffness of rotary motion hydraulic static pressure guide rail, and in the field of rotary motion hydraulic static pressure It is suitable for problems such as innovative development and large test volume, and achieves the effect of simple structure, reduced test volume and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

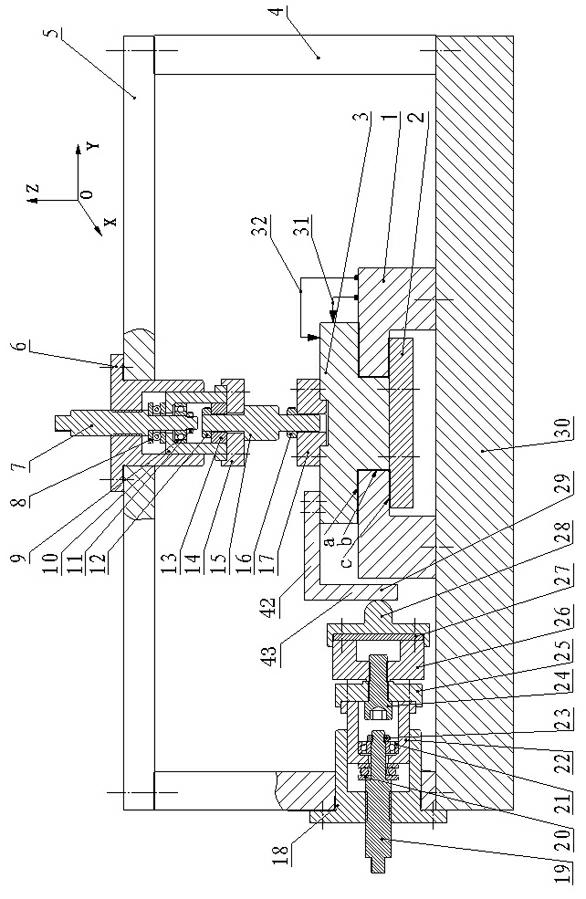

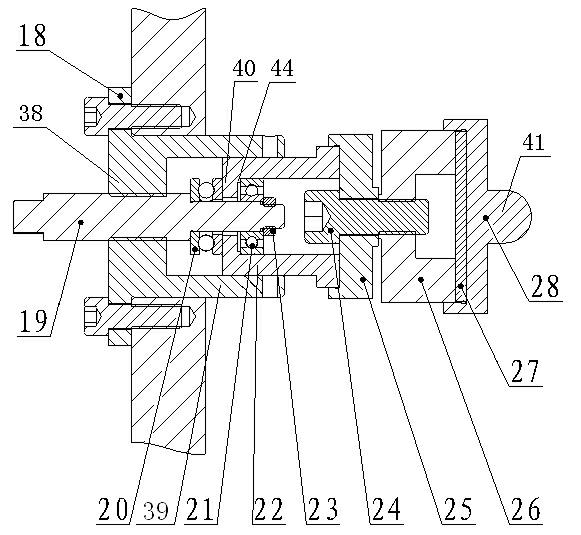

[0013] Such as figure 1 As shown, the present invention provides a test device for the axial stiffness and radial stiffness of a rotary hydraulic hydrostatic guide rail, including a platform 30, two columns 4 fixed on the platform 30, crossbeams 5 fixed on the two columns 4, Swivel components, axial load assemblies and radial load assemblies.

[0014] The rotary part is composed of the rotary assembly 3 (including the transmission of the rotary motion and the turntable) and the pressure plate 2 fixed at the bottom of the rotary assembly 3. The rotary part passes through the upper axial oil film a (ring shape) and the lower axial oil film c (circular shape) and radial oil film b (cylindrical shape) are supported in the rotary guideway seat 1, and the rotary guideway seat 1 is fixed on the platform 30. The upper axial oil film a, the lower ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com