Central heating system utilizing condensing and cooling heat in form of gradient

A technology of condensing cooling and heating, applied in hot water central heating systems, heating systems, household heating, etc., can solve problems such as environmental pollution, waste of water, electricity, chemicals, etc., and achieve cost reduction, environmental protection, and huge The effect of economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

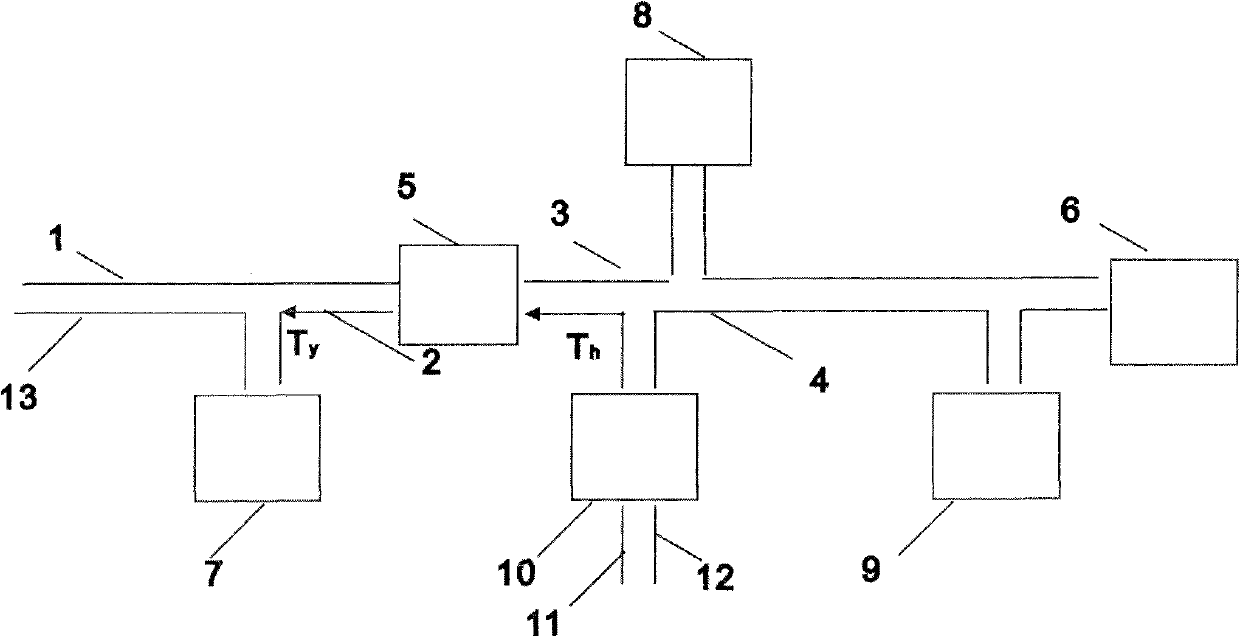

[0020] A centralized heating system for cascade utilization of condensation and cooling heat, as shown in Figure 1, includes: higher temperature cooling circulating water incoming water pipeline 1, cooling circulating water incoming water main pipeline or cooling device, cooling circulating water return pipeline device meeting the standard 13. The higher-temperature cooling circulating water inlet pipeline 1 is connected to the pre-heat exchange device 5, and the pre-heat exchange device 5 passes through the heating hot water pipeline 3 to the reheating device 8, and the outlet of the reheating device 8 is connected to the heat utilization The device 6 and the heat utilization device 6 are successively connected to the secondary heat utilization device 9 and the low-temperature thermal compensation device 10 through the heat supply and return water pipeline 4, and the low-temperature thermal compensation device 10 is respectively connected to the cooling circulating water inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com