Polygonal metal lamp shade and manufacturing method thereof

A production method and polygonal technology, applied in the direction of lampshades, lighting devices, lighting device parts, etc., can solve the problems of expensive crystal lamps, difficult market acceptance, and large environmental pollution, so as to achieve mass production and maintain high metal quality. Eye-catching effect, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

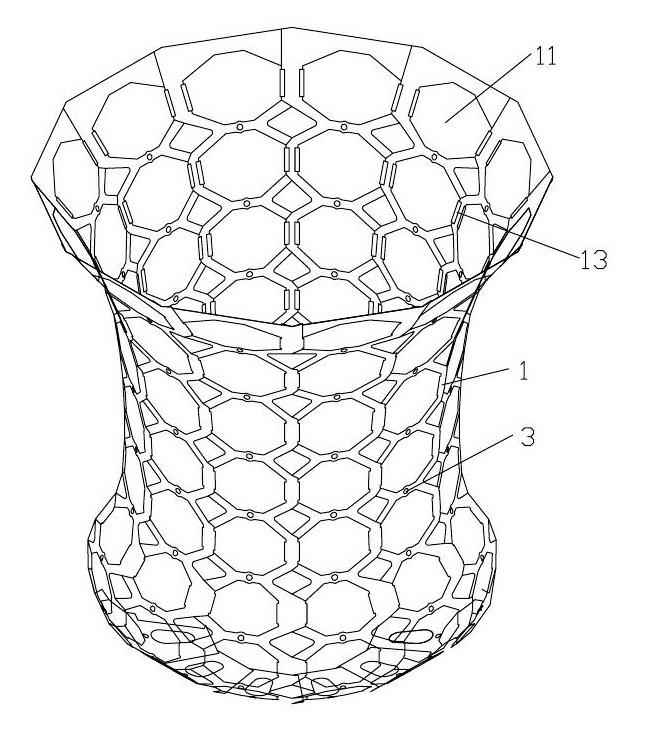

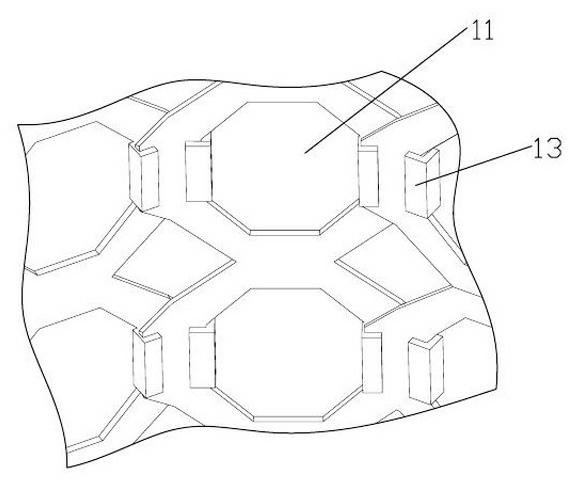

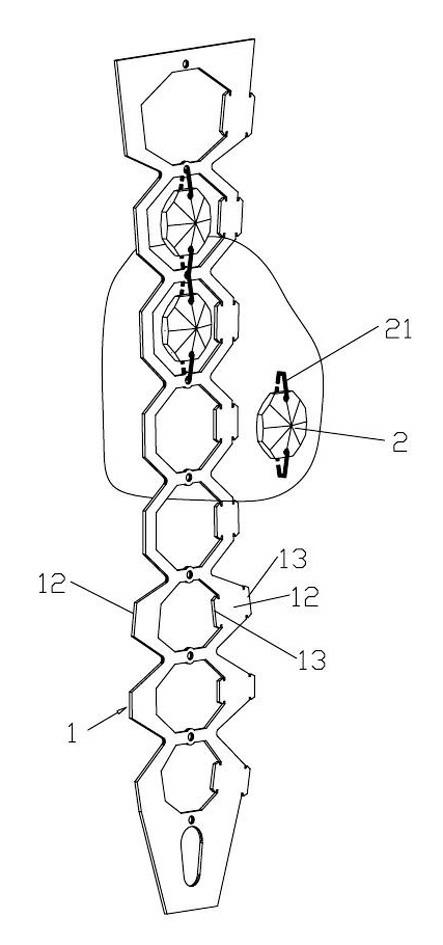

[0026] The present invention is a polygonal metal lampshade, which is a metal lampshade with a polygonal cross section. The metal lampshade is divided into a plurality of metal sheet units 1 according to the number of sides of the polygon. The metal sheet unit 1 is provided with a row from top to bottom for Place the through hole 11 of the crystal bead 2, and the metal sheet unit 1 is respectively provided with a crystal installation structure 3 connected with the crystal bead 2 above and below the through hole 11; a certain number of metal sheet units 1 are connected one by one to form a polygonal lampshade shape. The polygonal metal lampshade uses crystal beads as the light-transmitting parts to keep the crystal lampshade crystal clear; and the stamped and formed metal sheet units 1 are folded and connected one by one to form a lampshade shape. The present invention naturally forms a specific polygonal metal lampshade by surrounding several metal sheet units with specific sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com