Sealing chain

A technology for sealing parts and outer chain links, applied in the field of sealing chains, can solve the problem of difficulty in increasing the spherical shape r, etc., and achieve the effects of suppressing uneven contact pressure, improving tensile strength, and alleviating stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

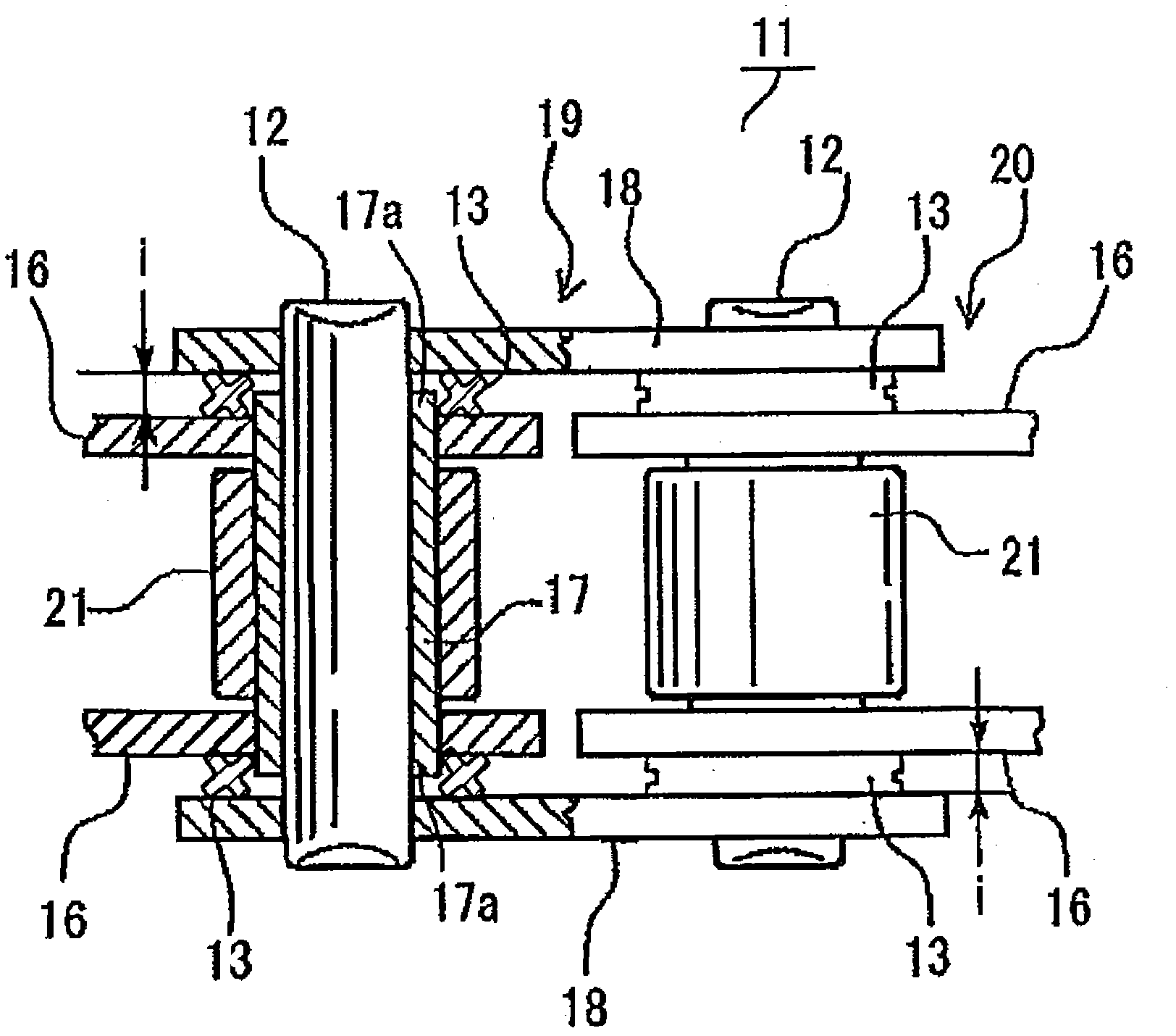

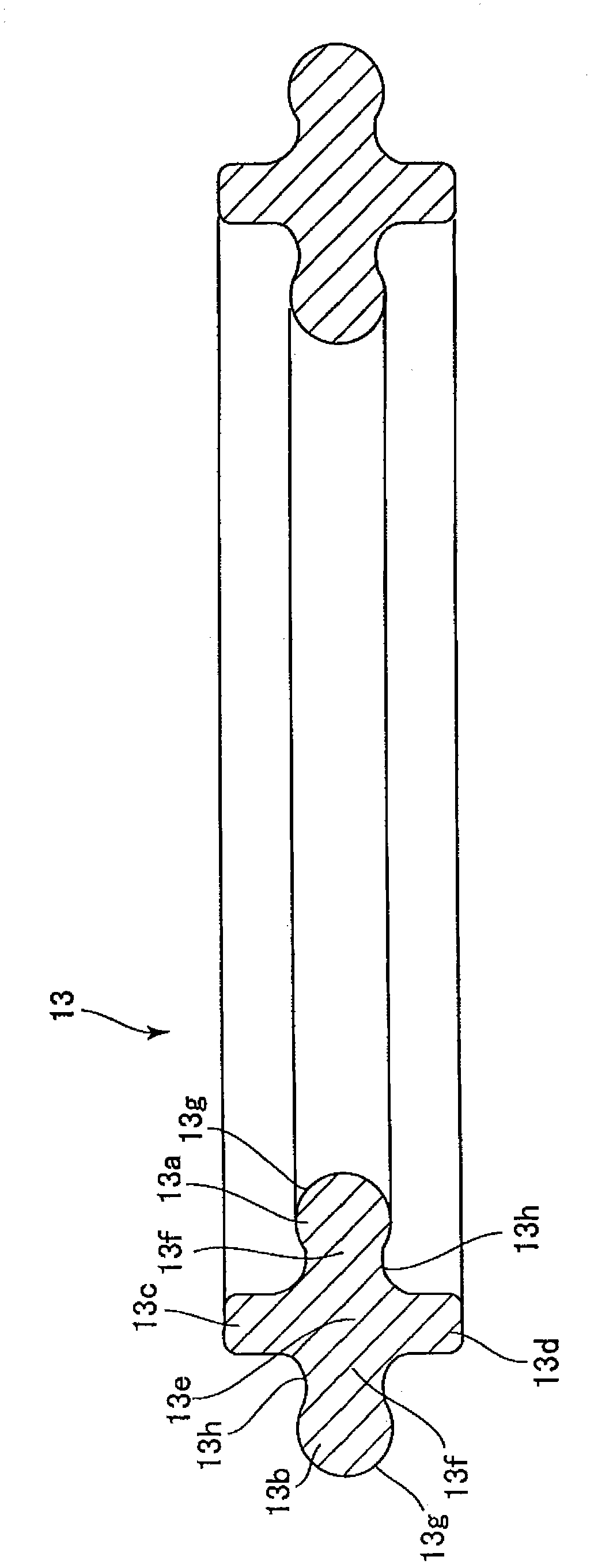

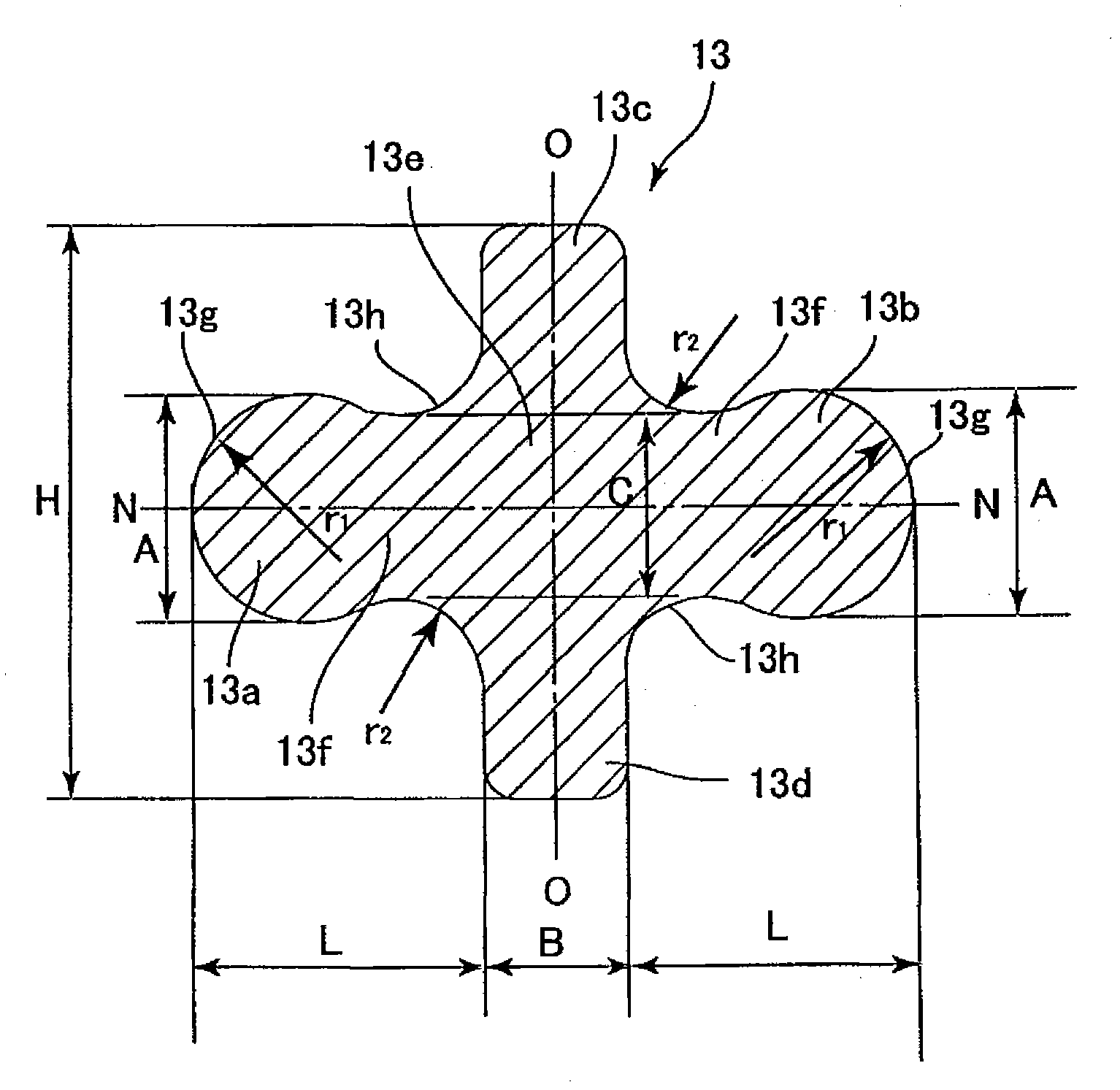

[0046] Below, use Figure 1 to Figure 8 , to describe the embodiment of the present invention. Such as figure 1 Shown, this sealing chain 11 is, for the outer (pin) chain link 19 that forms by the pin 12 connecting the two ends of two oval outer (pin) link plates 18 made of steel, and the outer (pin) link 19 formed by the bushing 17 The inner (roller) link 20 formed by connecting the two ends of the inner (roller) link plates 16 having the same shape is connected in a ring shape by inserting the pin 12 into the bush 17 . In addition, the roller 21 is rotatably fitted to the bush 17 , and the bush 17 is fixed so as to protrude by a predetermined amount from the outer surface of the inner link plate 16 . Furthermore, a seal member (seal ring) 13 according to the present embodiment is interposed between the inner link plate 16 and the outer link plate 18 so as to surround the protruding portion 17 a of the bush 17 . The clearance i{between the outer link plate 18 and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com