Pumping system and distributing valve thereof, and concrete transporting machinery

A pumping system and distribution valve technology, which is applied in the field of concrete mixing pump trucks and concrete conveying machinery, can solve problems such as adaptability, service life is difficult to meet actual needs, the application of concrete mixing pump trucks is difficult, and the requirements for driving mechanisms are high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0040] It should be noted that the technical solution provided by the present invention is not limited to pumping or conveying concrete, and can also be used to convey ash, mud or other viscous materials.

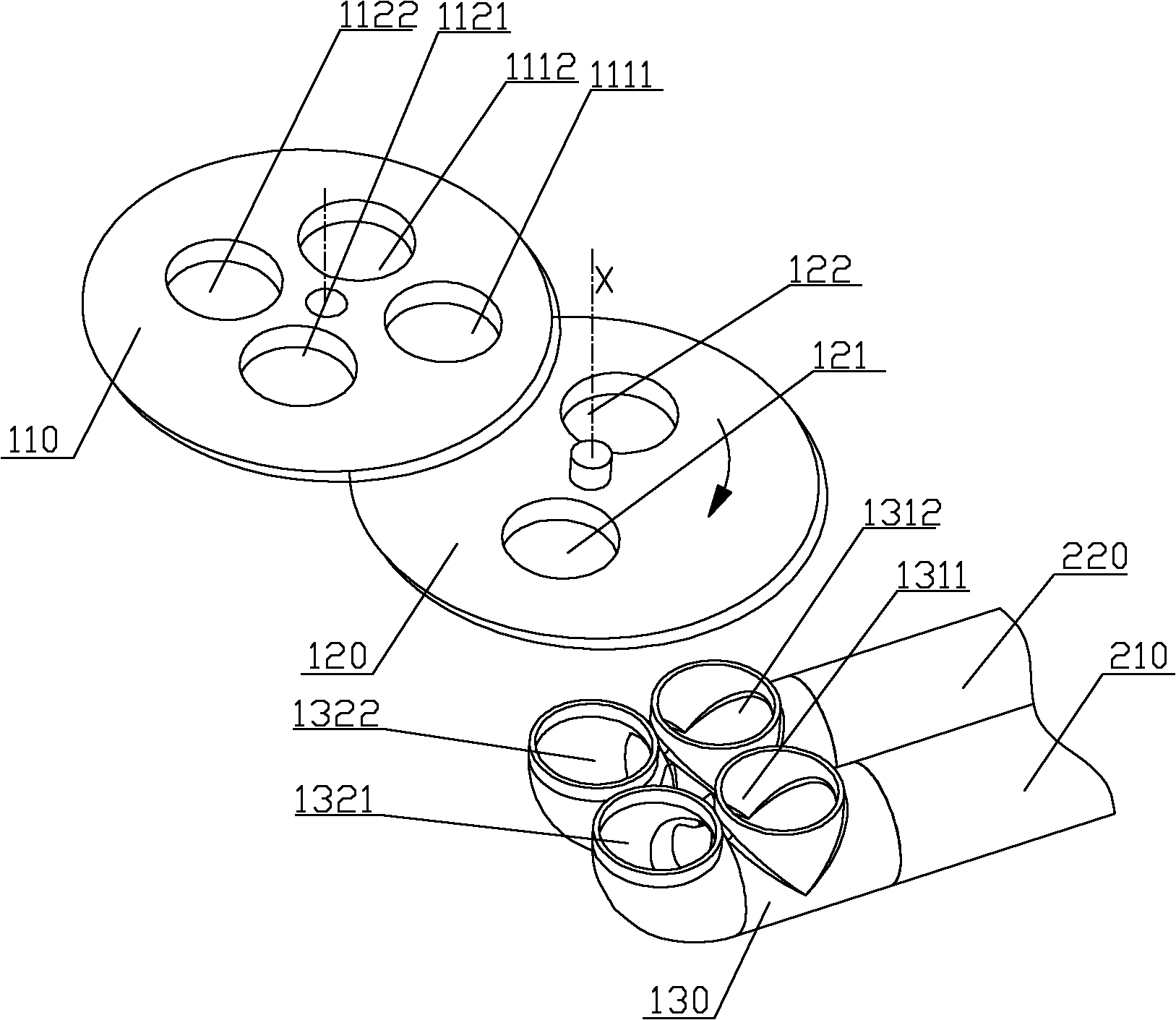

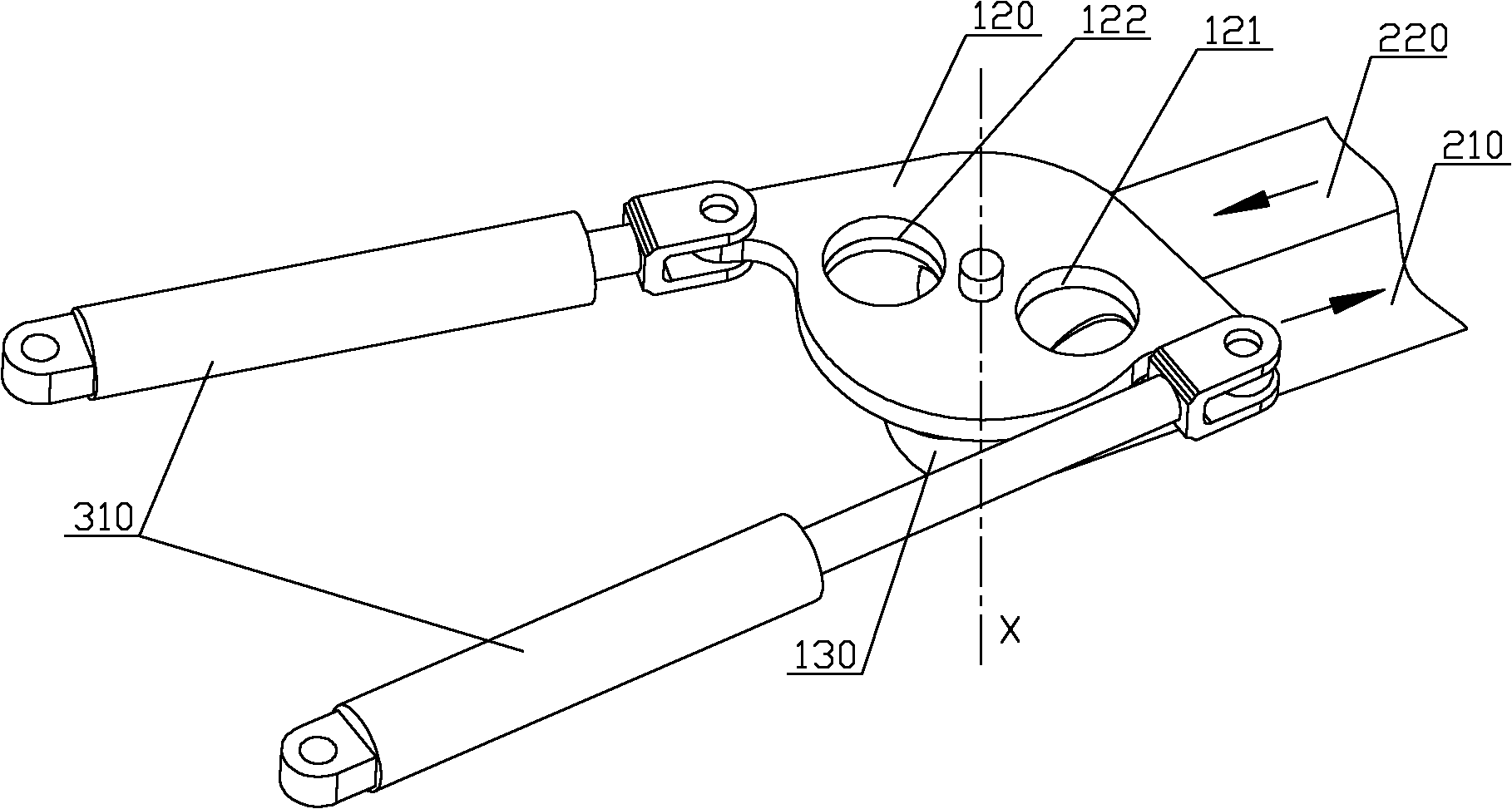

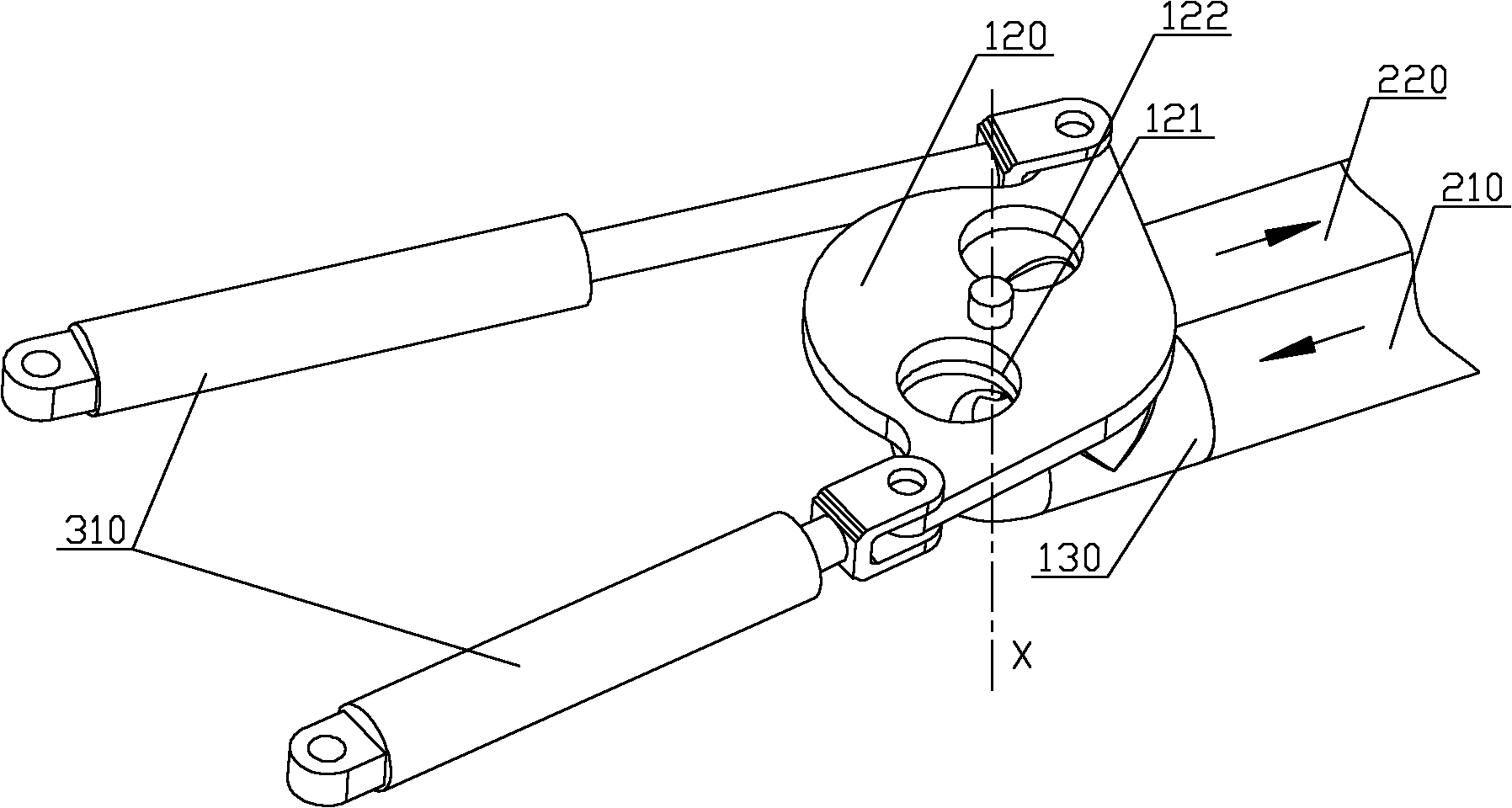

[0041] Please refer to figure 1 and figure 2 , figure 1 It is a schematic diagram of the exploded structure of the distributing valve of the pumping system provided by the embodiment of the present invention, figure 2 is a schematic structural view of the distribution valve of the pumping system provided by the embodiment of the present invention when it is in the first state, image 3 It is a schematic structural diagram of the distribution valve of the pumping system provided by the embodiment of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com