Building curtain wall structure

A curtain wall and building technology, applied in the field of installation structure improvement, can solve the problems of large installation workload, long construction period, and high overall cost, and achieve the effects of ensuring progress and quality, simple and safe installation, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below with reference to the drawings.

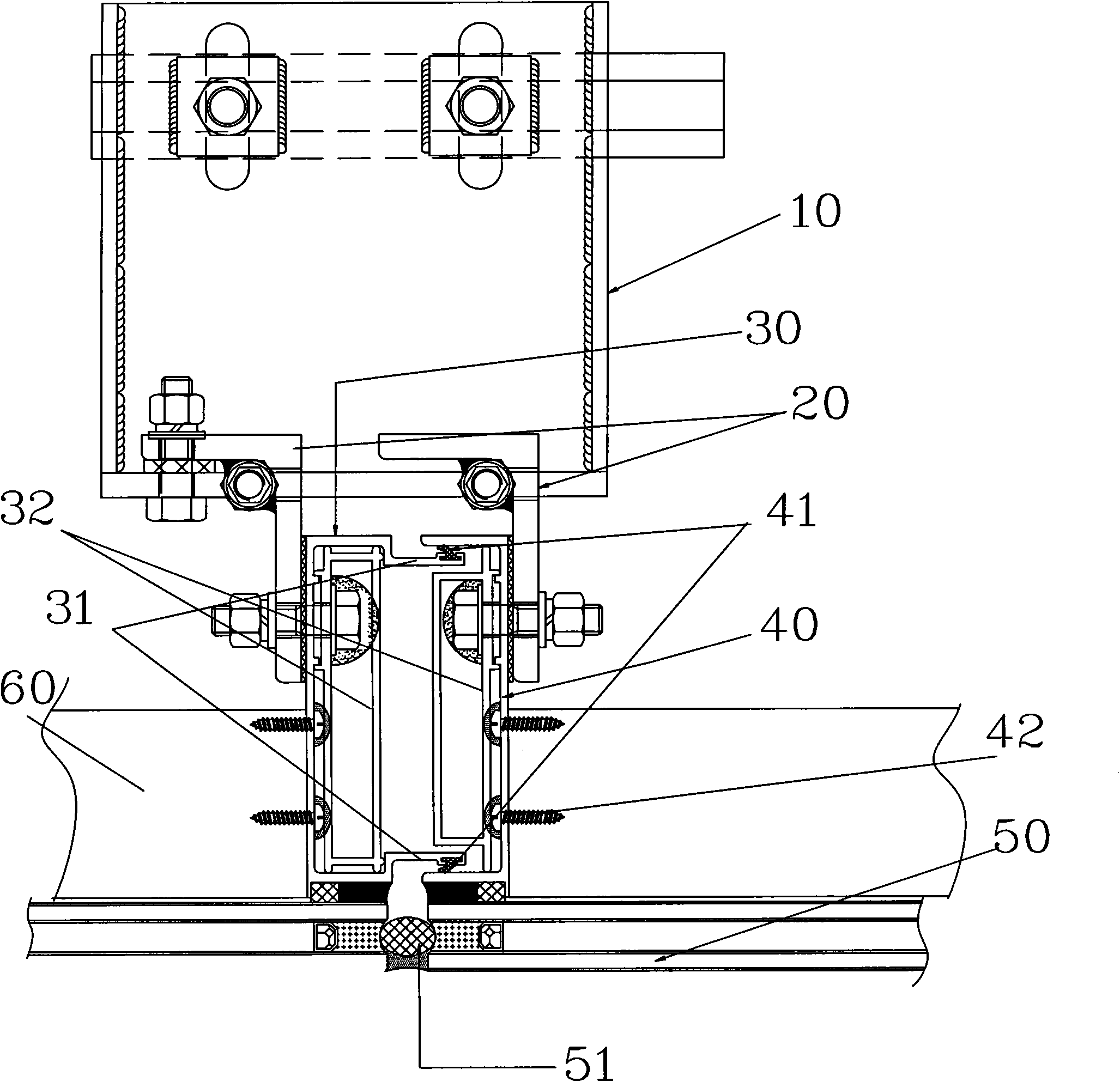

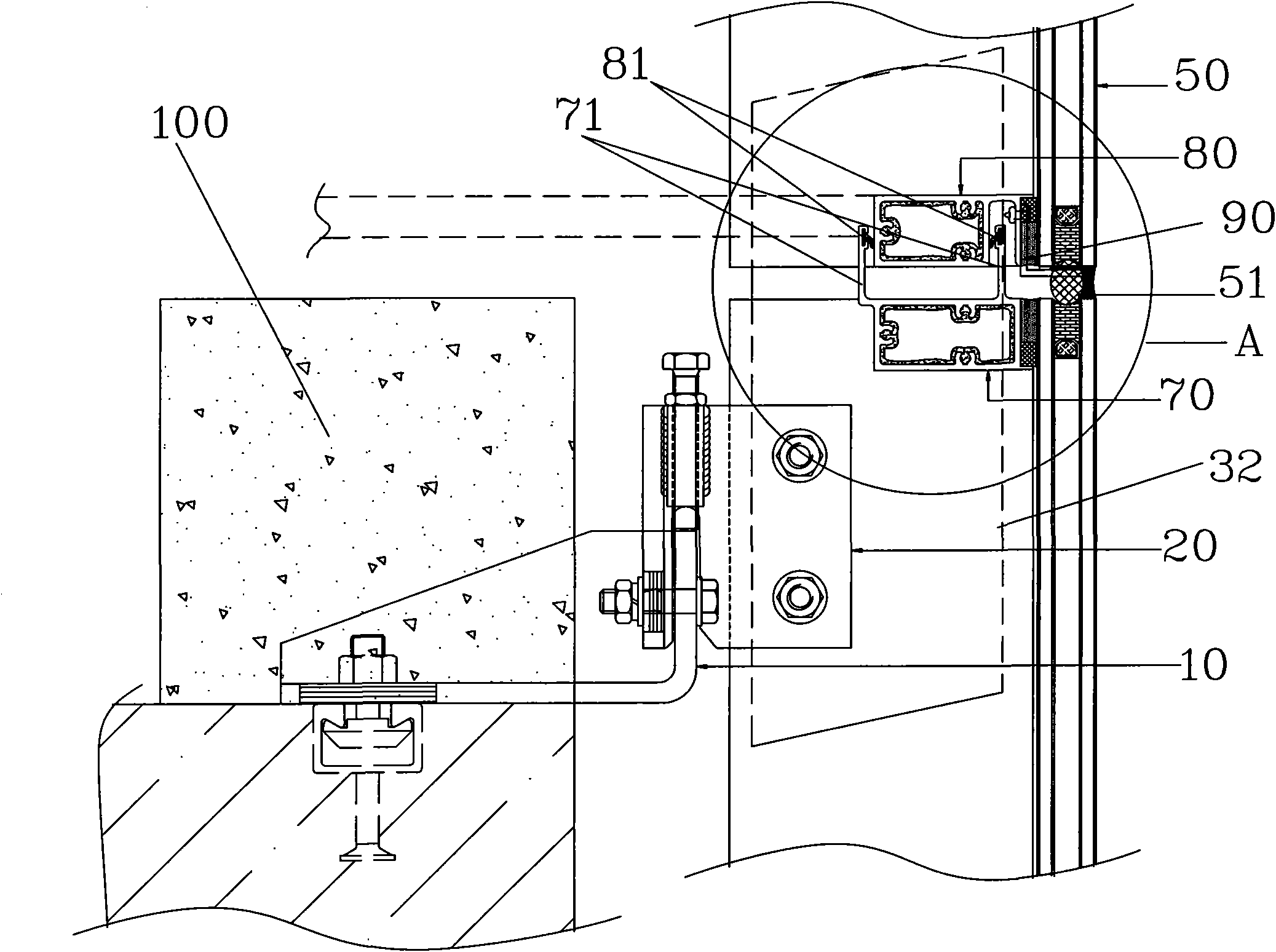

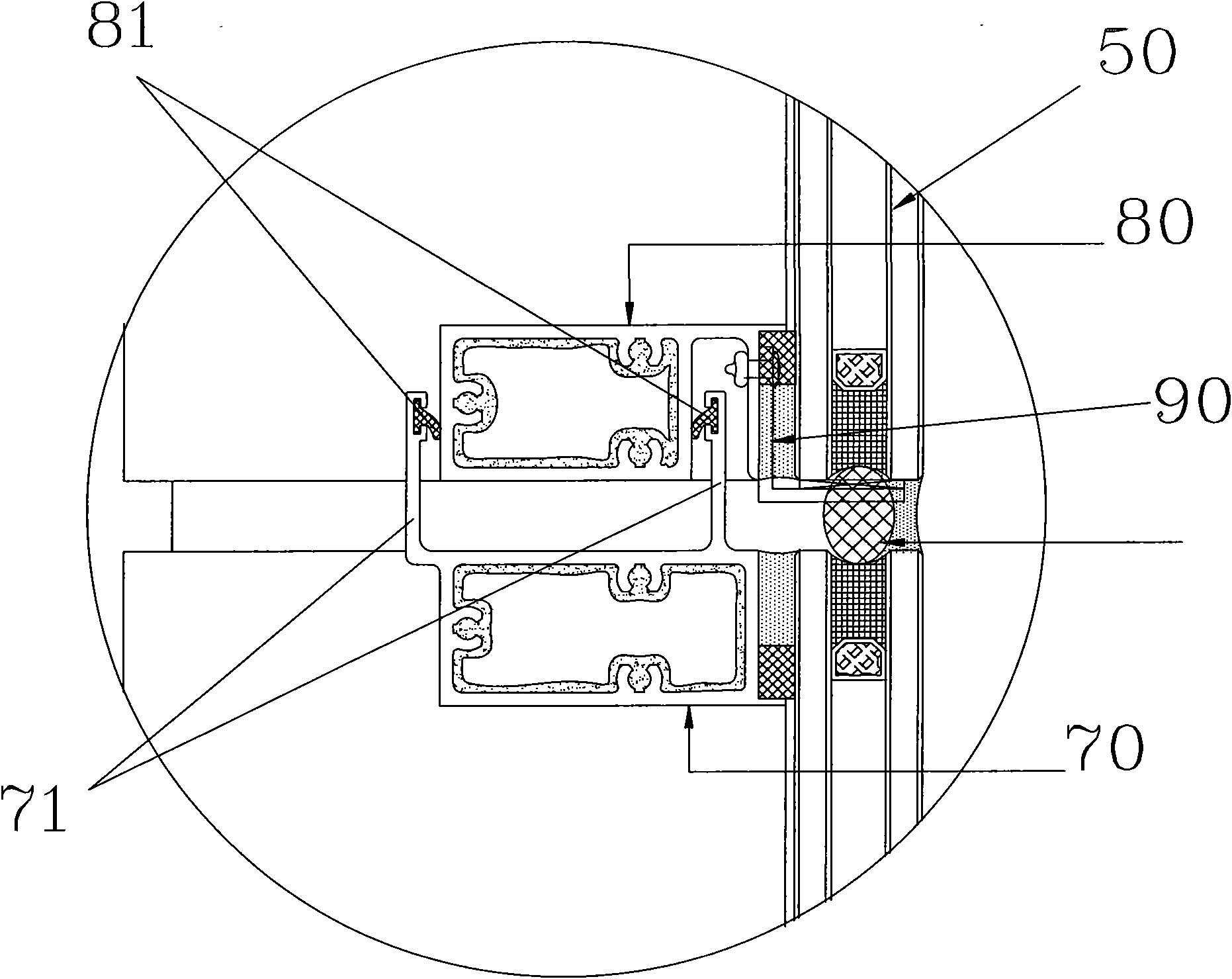

[0025] The building curtain wall structure of preferred embodiment of the present invention is shown as figure 1 shown, see also figure 2 , the building curtain wall structure includes a support 10 for connecting the fixed body 100 , and also includes a plurality of profiles fixedly connected with the curtain wall surface material 50 . Among them, the profile is a frame structure composed of horizontal material (including: upper horizontal material 70 and lower horizontal material 80 ), vertical material (including: female vertical material 40 and male vertical material 30 ), the upper horizontal material 70 and the lower horizontal material 80 Relatively arranged, the female vertical material 40 and the male vertical material 30 are relatively arranged.

[0026] Wherein the upper horizontal material 70 and the lower horizontal material 80 between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com