Refractory castable material containing ferrovanadium dregs

A technology of refractory castables and vanadium-iron slag, applied in the field of refractory castables, can solve the problems of resource waste, failure to be recycled, environmental pollution, etc., and achieve excellent refractory performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

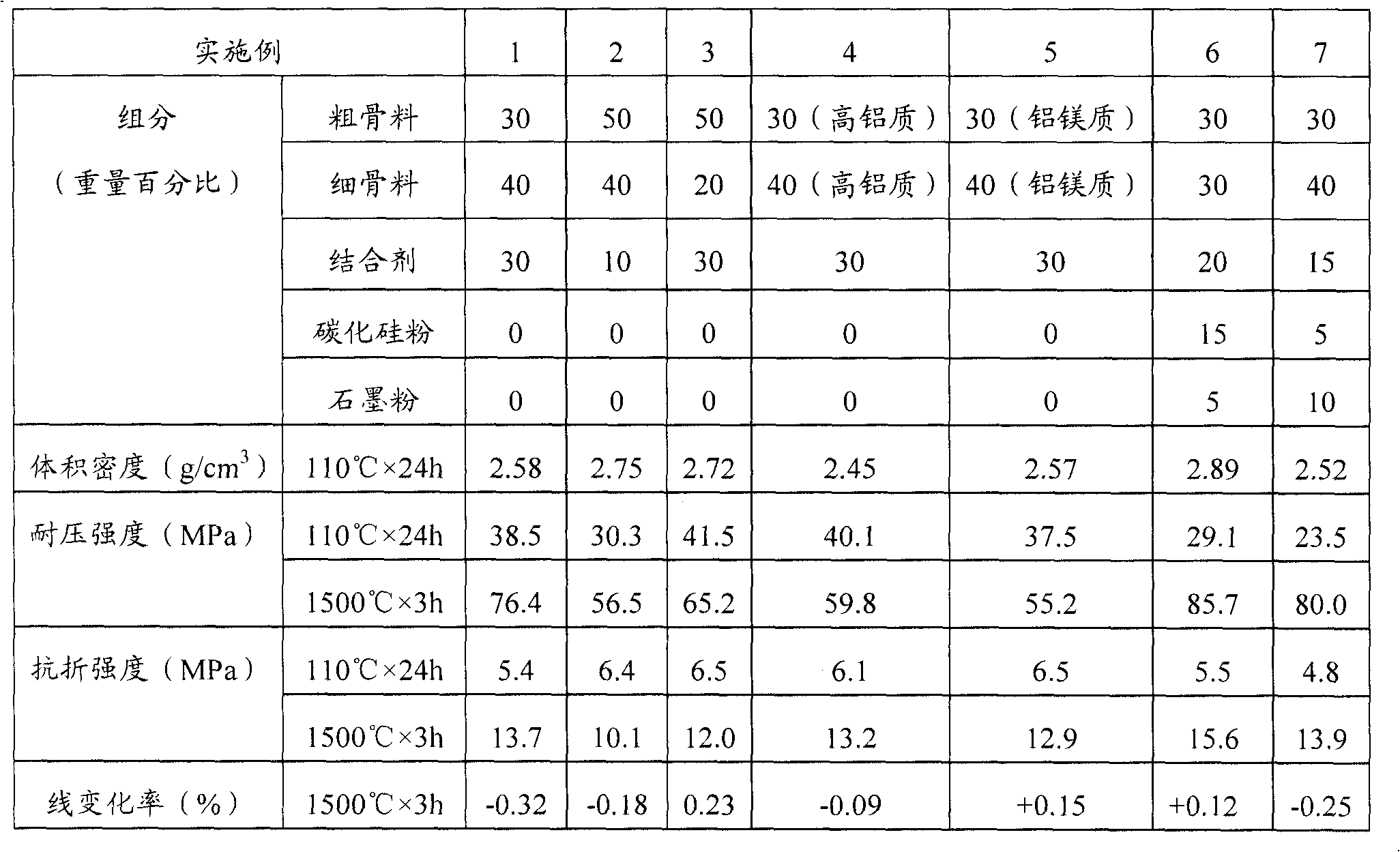

[0010] Exemplary embodiments according to the present invention will be described in detail below.

[0011] The refractory castable according to the present invention is mainly formed of coarse aggregate, fine aggregate and a binder formed of fine powder of ferrovanadium slag.

[0012] The ferrovanadium slag used in the present invention comprises 78%~83% Al by weight percentage 2 o 3 , 10% to 17% of CaO, 1.0% to 2.5% of MgO, 0.2% to 0.8% of FeO, 0.6% to 0.8% of SiO 2 And 1.3% to 4.0% of vanadium oxide. In addition, ferrovanadium slag is mainly composed of 35% to 40% calcium aluminate phase, 45% to 55% monocalcium dialuminate phase, 4% to 7% α-Al 2 o 3 phase, 7%-8% glassy phase, 1%-3% metal phase and 3%-5% spinel phase.

[0013] Coarse aggregate, fine aggregate and binder will be described in detail below.

[0014] The refractory castable according to the present invention comprises 30%-50% of coarse aggregate, 20%-40% of fine aggregate and 10%-30% of binder formed of va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com