Automatic steamed vermicelli roll machine

A sausage powder machine, automatic technology, applied in the field of automatic sausage powder machine, can solve the problems of poor consistency of sausage powder, low production efficiency of sausage powder machine, affecting the sales volume of sausage powder, etc., to improve production efficiency, improve quality and taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

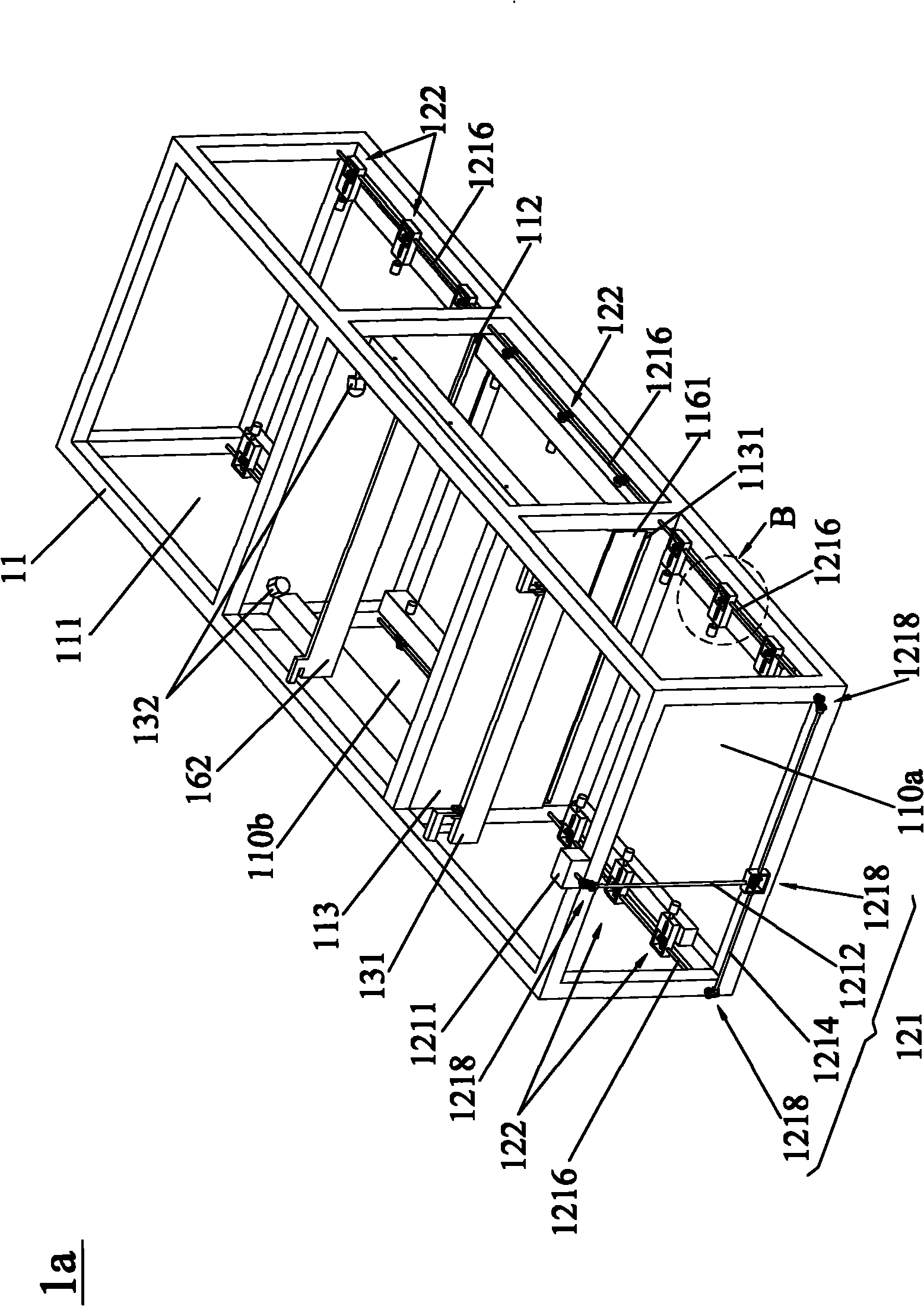

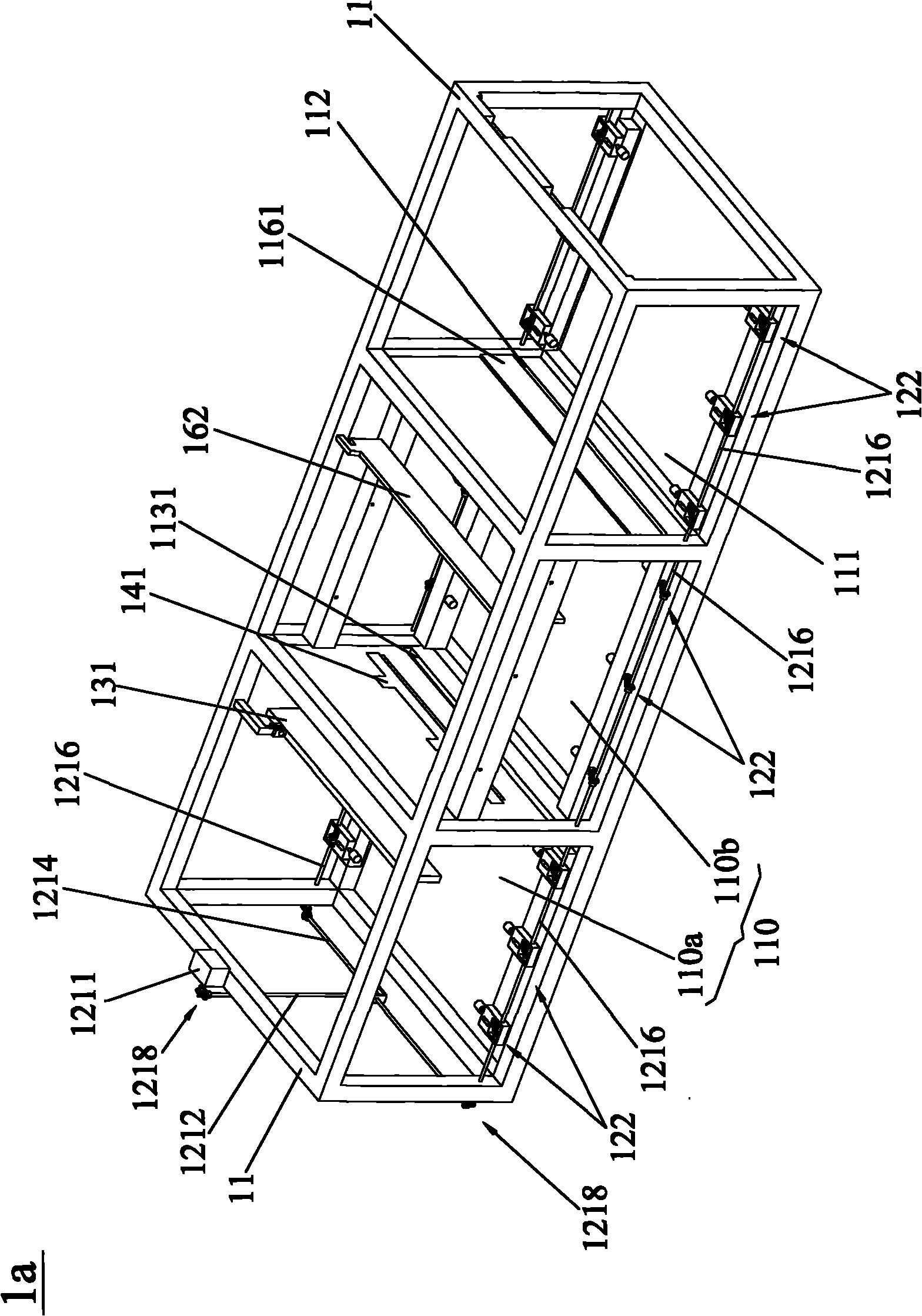

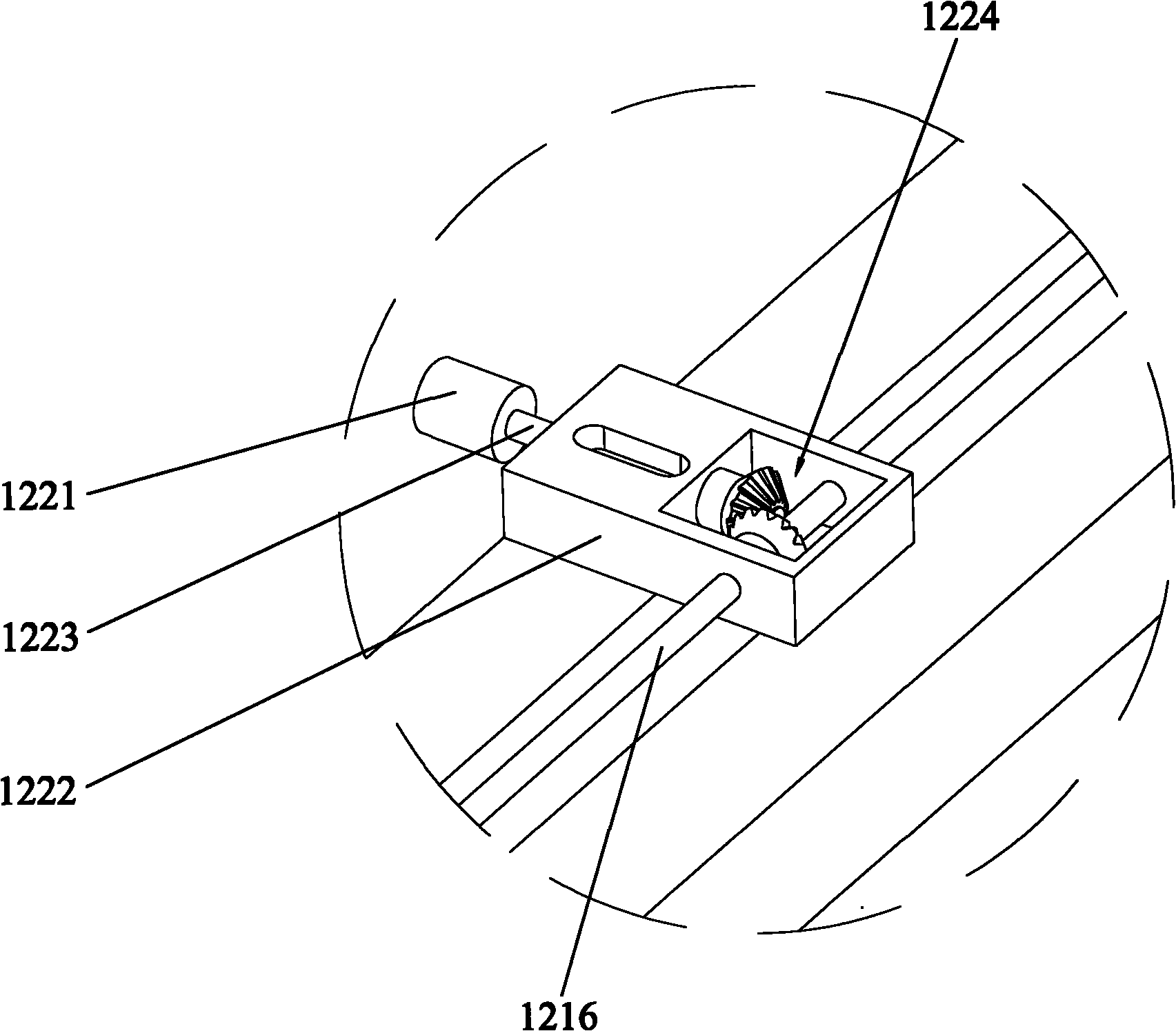

[0043] see Figure 1 to Figure 10 , Figure 1 to Figure 10 The first embodiment of the automatic intestine powder machine of the present invention is shown. exist figure 1 with Figure 5Among them, the automatic rice roll machine 1a of this embodiment is used to automatically process the raw materials for rice rolls, which includes a tray 10, a frame body 11, a tray conveying mechanism, an oiling device 13, a pouring device 14, and a rice roll filling core. Feeder 15, intestinal powder scraper, some sensors and controllers (not shown in the figure). The pallet 10 is accommodated in the frame body 11, and the pallet conveying mechanism drives the pallet 10 to move in the frame body 11, and the oil brushing plate 131 of the oiling device 13 first automatically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com