Layered runner motor shell of dust collector

A vacuuming motor and stratified flow technology, applied in the direction of vacuum cleaners, casings/covers/supports, electrical components, etc., which can solve the problems of insignificant noise reduction effect and short gas flow passages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

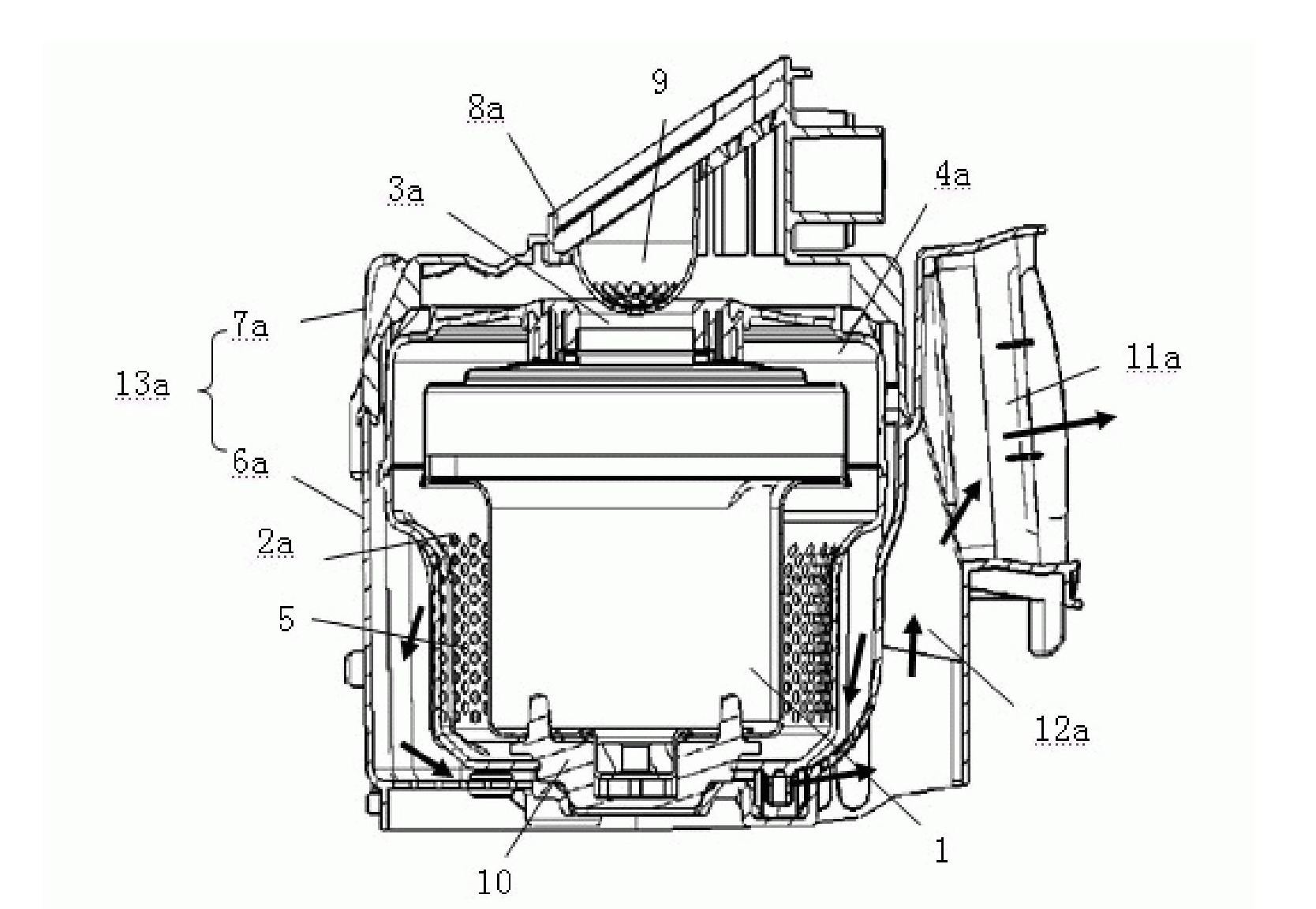

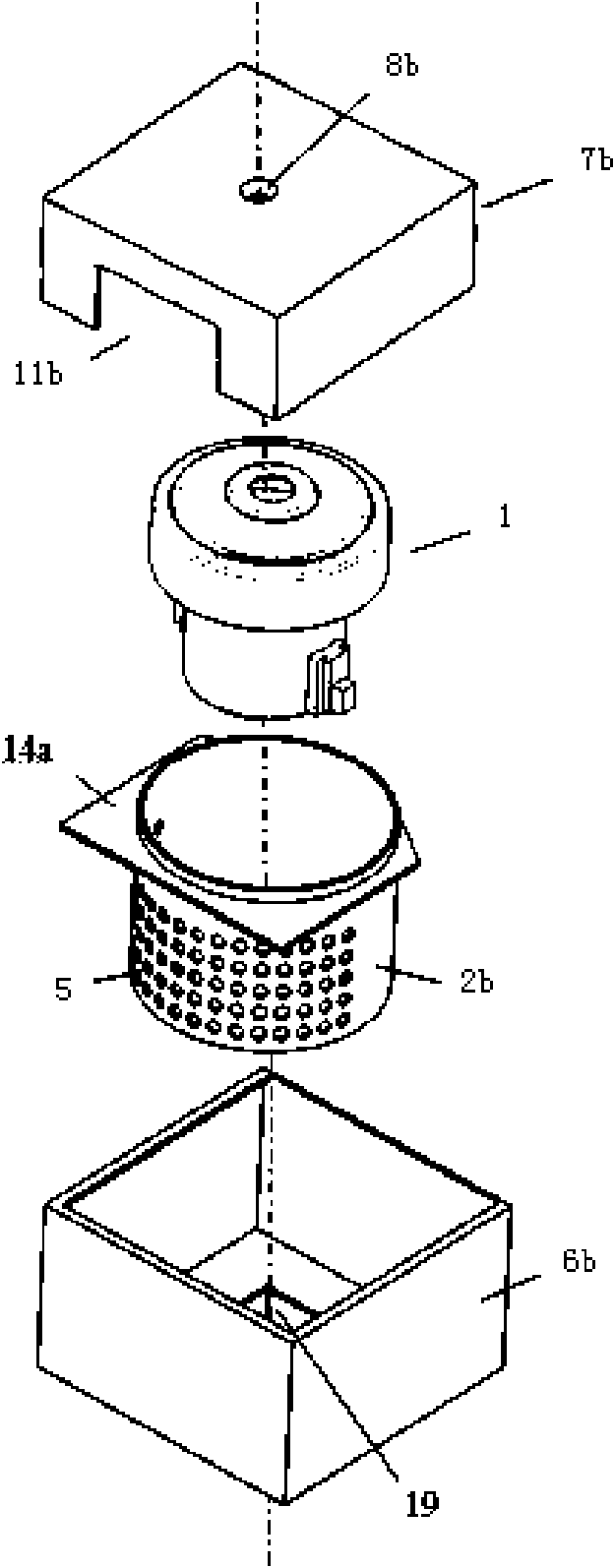

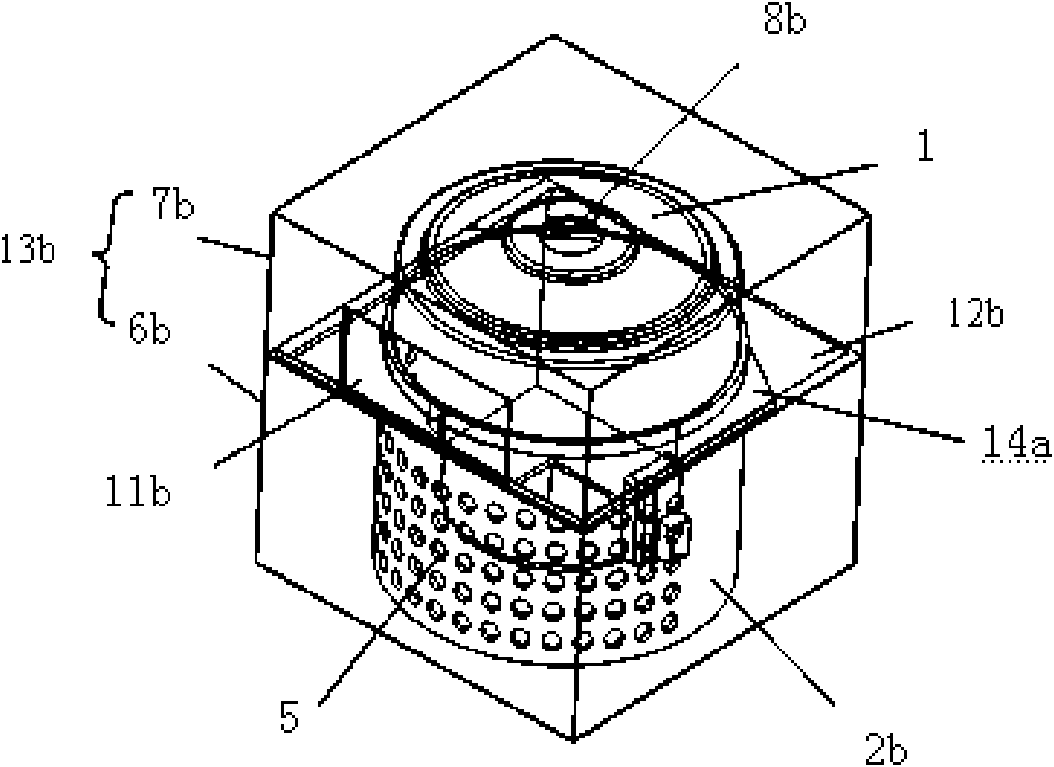

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0034] A layered channel motor casing of a vacuum cleaner, comprising an inner casing 2b. , 13c, the housing 13b, 13c is composed of the housing body 6b, 6c and the housing cover 7b, 7c, the housing air inlet 8b, 8c formed on the top of the housing cover 7b, 7c, and the exhaust port for discharging gas from the housing 13b, 13c 11b, 11c, and in the outer shell 13b, 13c are formed the diaphragm 14a, 14b that partly separates the inner space, and the vent hole 5 is formed in the diaphragm 14a, 14a on the side of the center line of the inner casing 2b, 2c. 14b below the surrounding wall.

[0035] The horizontal partition 14a of the vacuum cleaner layered runner motor casing is formed on the outer peripheral wall of the front part of the inner casing 2b. Thereby, the passage on the upper layer of the partition and the passage on the lower layer of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com