Intelligent control circuit of hot air seam sealing machine

A technology for controlling circuits and sealing machines, applied to electrical program control, tools for sewing clothes, program control in sequence/logic controllers, etc., to improve grade and quality, good bonding effect, convenient input instructions and observation The effect of the operating state of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

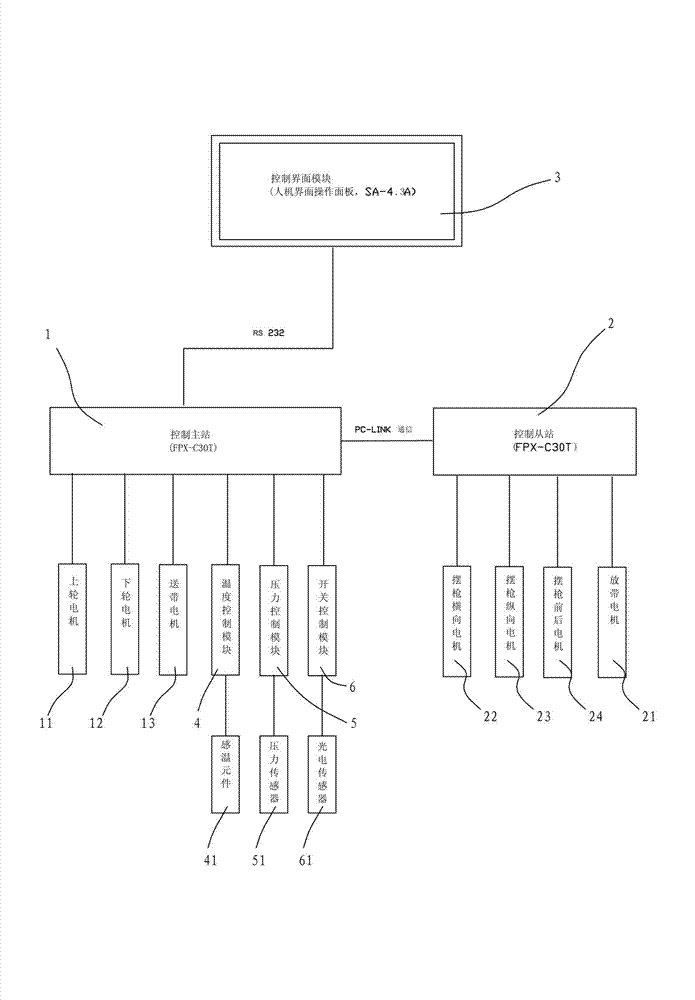

[0021] Such as figure 1 As shown, the intelligent control circuit of a hot air seam sealing machine disclosed in the present invention includes a control master station 1 and a control slave station 2 that independently control one or more motors, and the two communicate with each other through the PC-Link bus ; The master control station 1 is also connected to the control interface module 3 that inputs control commands and displays the working status and the temperature control module 4 that controls the working temperature of the heating air gun.

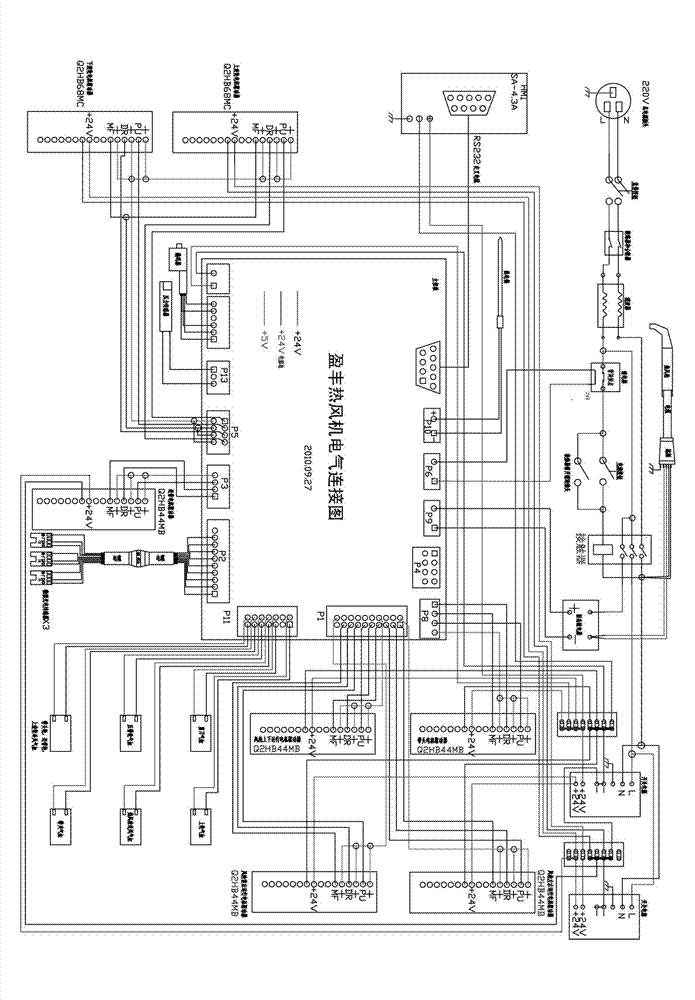

[0022] In specific implementation, such as figure 2 As shown in the circuit diagram, the intelligent control circuit of the hot air seam sealing machine includes a control master station 1 and a control slave station 2. The cores of both are programmable logic controllers. In this embodiment, Panasonic produced FPX-C30T high-performance programmable logic controller, each FPX-C30T module contains 16 points of 24V DC input, 14 po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com