Thin strip continuous cast loop detection and control method

A control method and looper technology, applied in the direction of electrical program control, measuring devices, instruments, etc., can solve the problems of uncertain effect of free looping, complex deformation of strip steel, high protection requirements of measuring devices, etc., and achieve direct and reliable adjustment methods, Fast adjustment speed, simple and reliable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with embodiment.

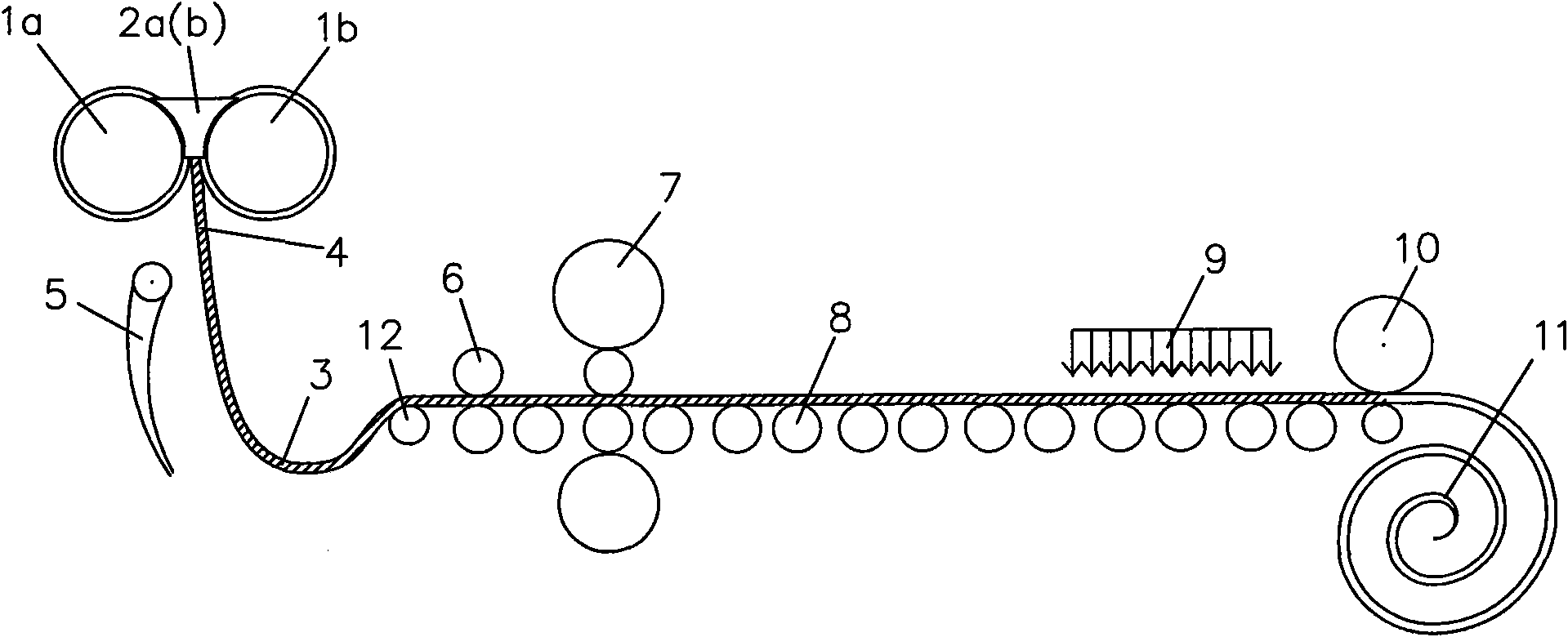

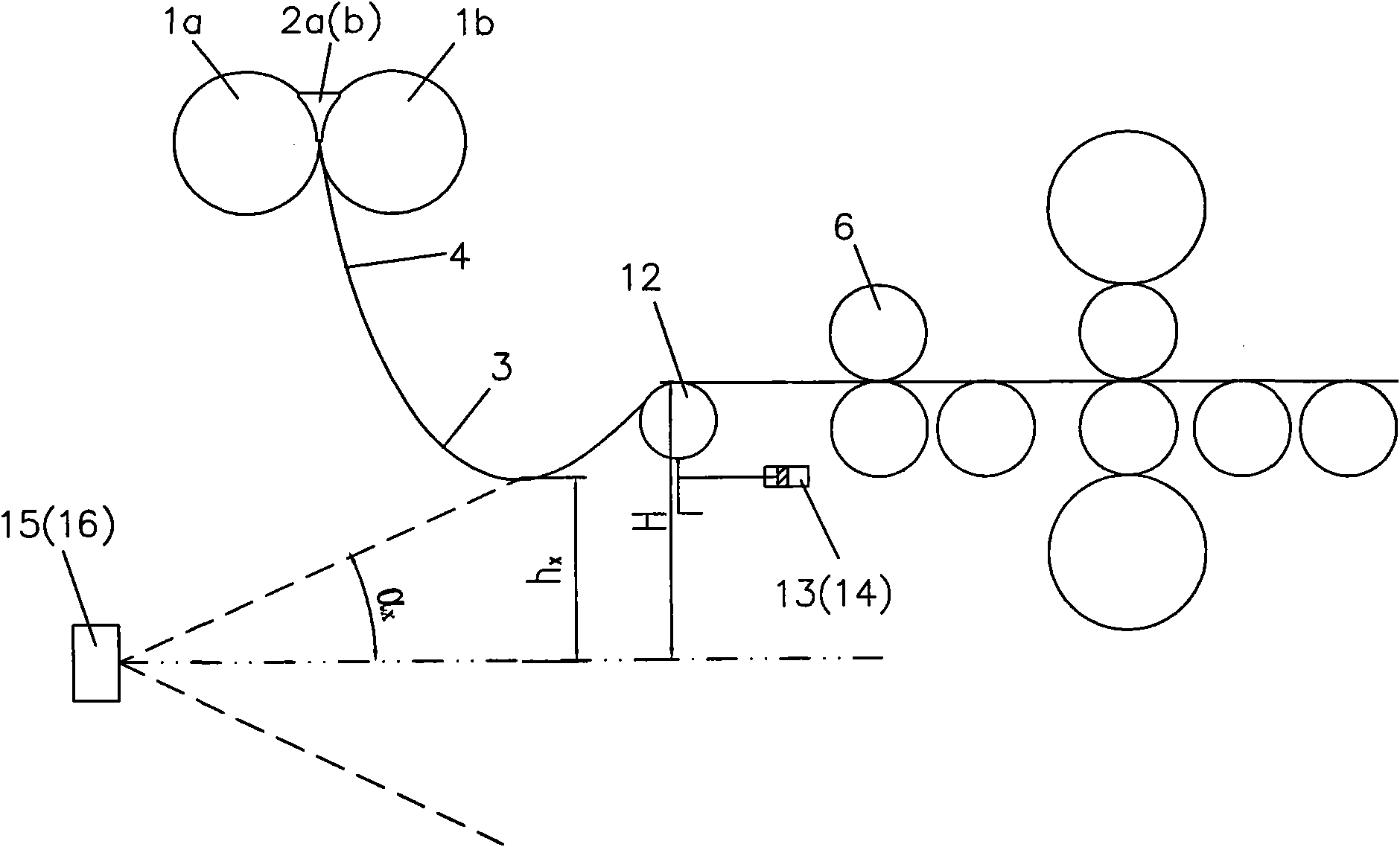

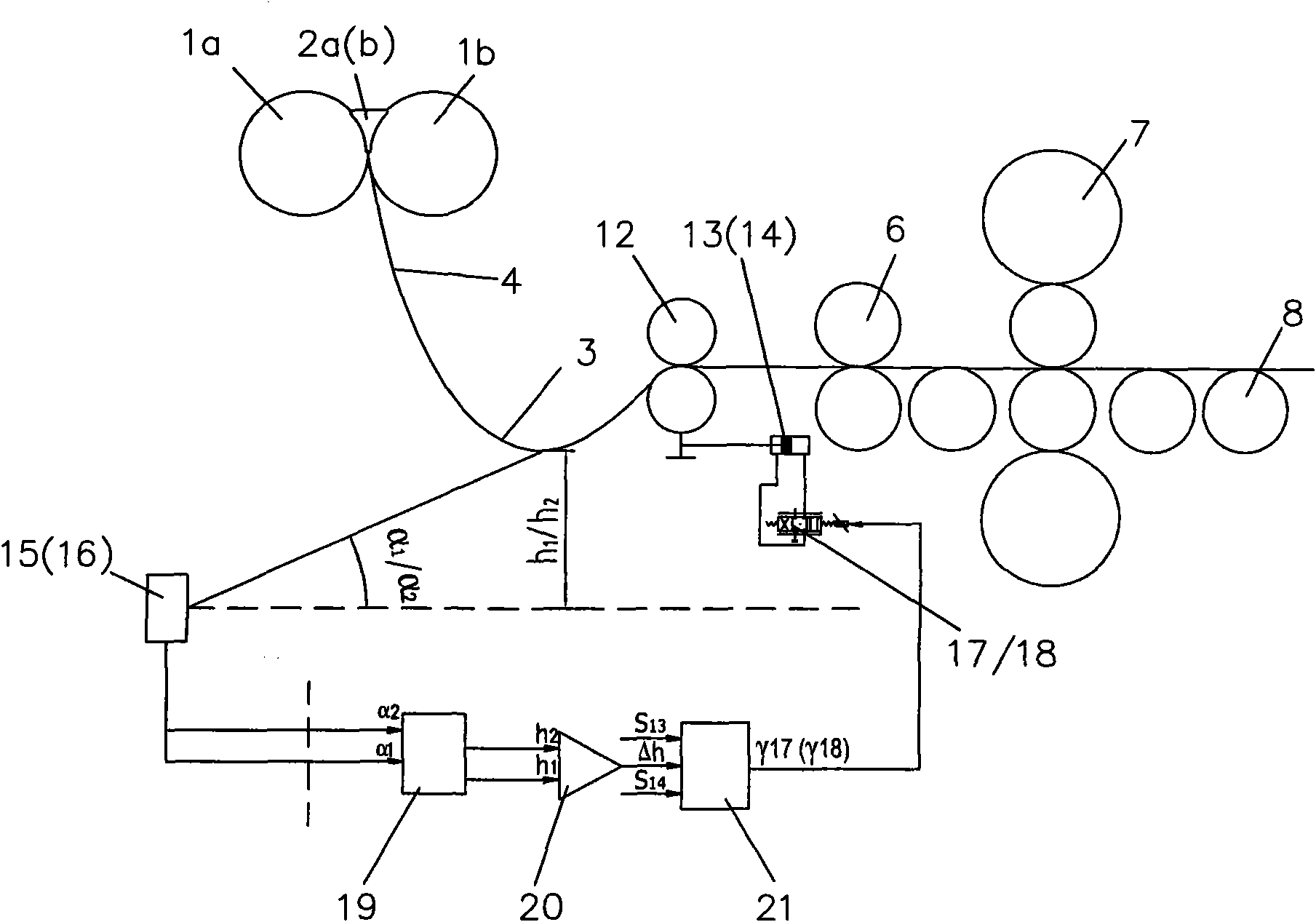

[0045] see Figure 2 ~ Figure 4 , the looper detection method of the present invention, at first, from the two ends of the outer arc side of the looper 3, a set is respectively placed on the left and right to detect the height h of both sides of the looper 1 、h 2The loop detectors 15, 16 of the two loop detectors 15, 16 are equal to the horizontal and vertical distances of the casting rollers 1a, 1b; the positions of the two loop detectors 15, 16 are adjustable along the width direction of the casting belt 4, The loop detectors 15 and 16 are within 15-50mm from the edge of the casting belt 4; the loop detectors are in the form of infrared photosensitive cells;

[0046] The two loop detectors start to work, respectively measure the loop height h at both ends of the free loop along the width direction of the casting belt 1 、h 2 ;

[0047] Simultaneously, the pinch roll 6 rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com