Method for detecting hot strip steel unequal-height free loop

A detection method and looper technology, which can be applied to measurement devices, instruments, optical devices, etc., can solve problems such as measurement errors, and achieve the effects of reducing detection errors, simple and reliable equipment, and easy installation and debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with an embodiment.

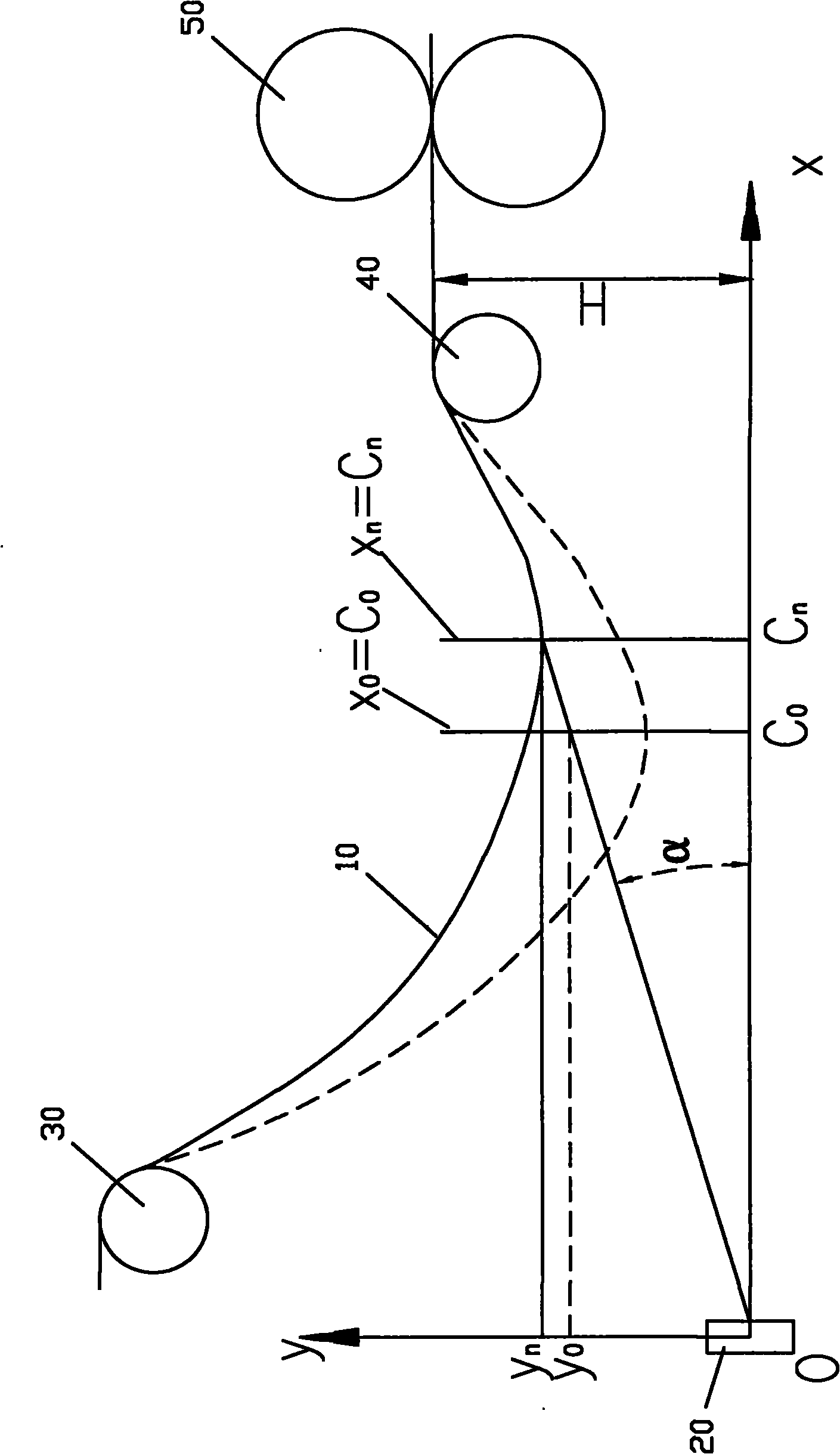

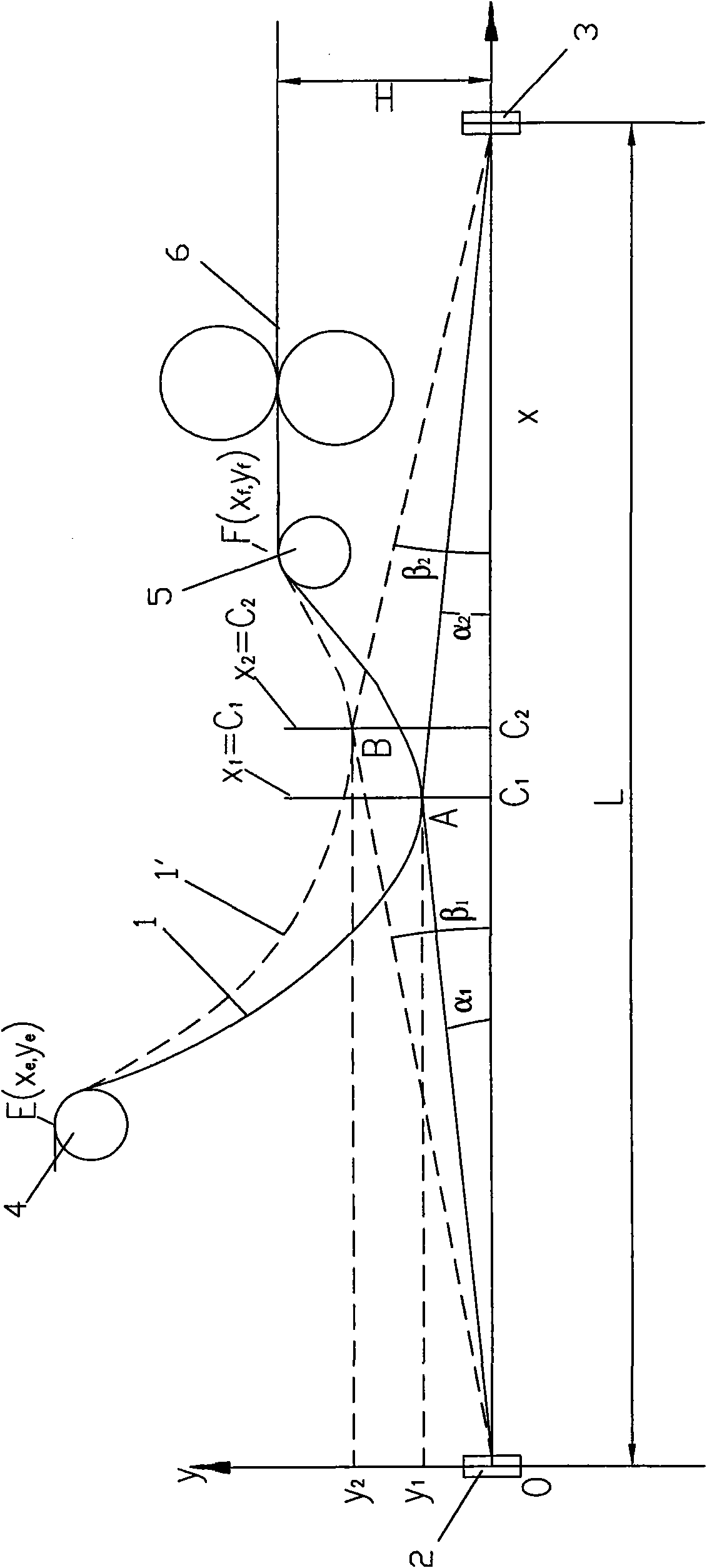

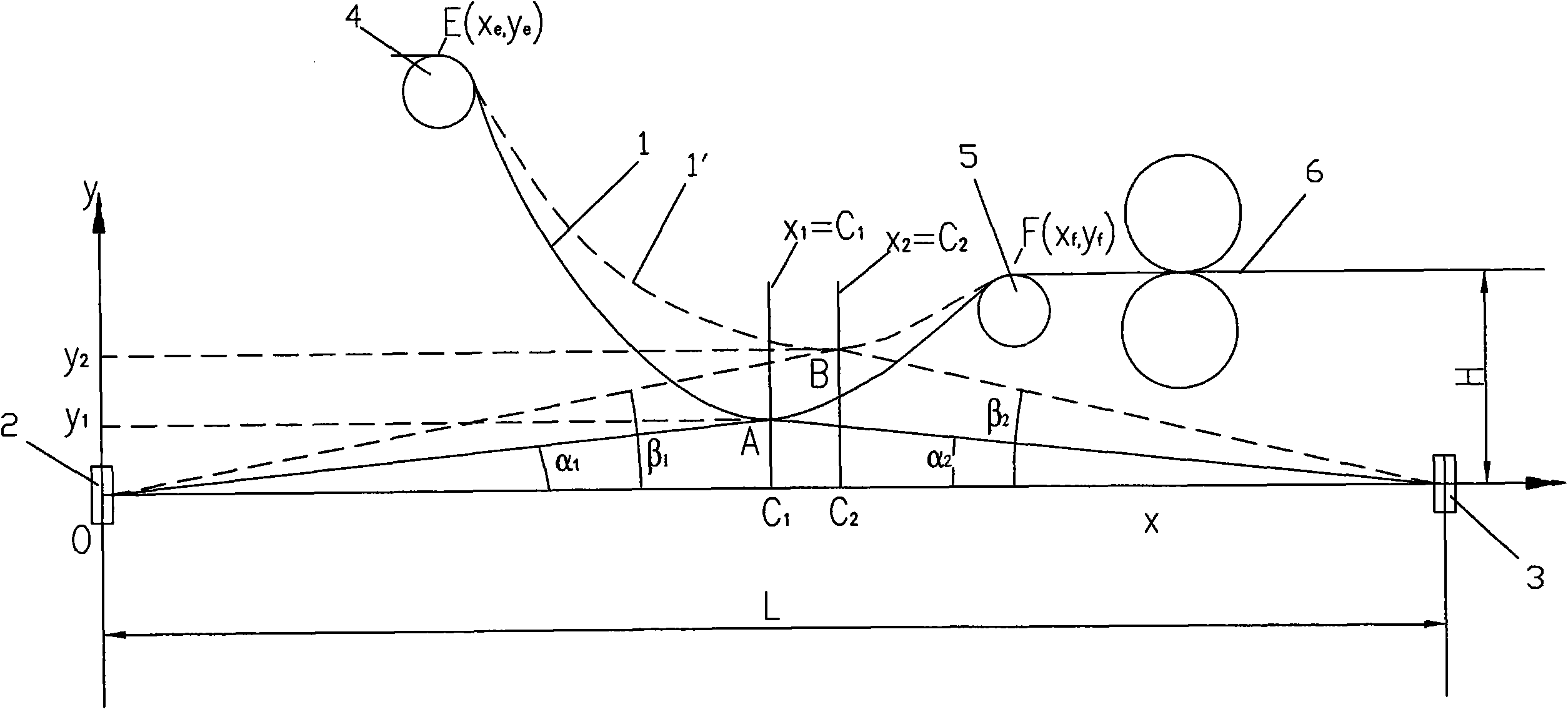

[0051] see figure 2 , the detection method of the unequal-height free looper of hot strip steel of the present invention, at first, install a set of infrared looper detector 2,3 respectively, two looper detectors 2 at the inner and outer arc sides of hot steel strip free looper 1 , 3 are located on the same horizontal plane, and the distance between the two loop detectors 2 and 3 is equal to the distance from the casting roll 4 and the loop guide roller 5, and both are located outside the casting roll 4 and the loop guide roller 5; the loop detector 2 , 3 are installed parallel to the casting belt 6 forward direction and perpendicular to the width of the casting belt 6, and the centerlines of the two loop detectors 2, 3 scanning detection angles are the same straight line.

[0052] The two loop detectors 2 and 3 start to work and measure the same detection point on the free loop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com