Solid waste incineration treatment system and treatment process of solid waste incineration treatment system

A treatment system and treatment process technology, applied in the field of drilling solid waste incineration treatment system and its treatment process, can solve the problems of incomplete treatment of drilling solid waste, environmental pollution, etc., achieve high practical value and promotion value, no technical requirements, The effect of maintaining a good relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

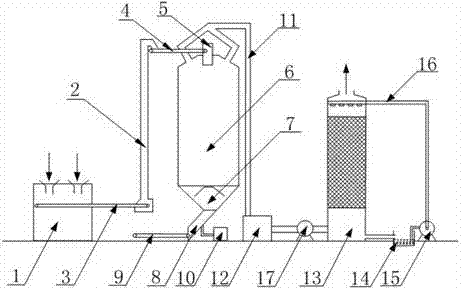

[0029] like figure 1 As shown, the solid waste incineration treatment system is mainly composed of a feeding system, an incineration system, an unloading system and an exhaust gas treatment system. The above-mentioned systems will be described separately below.

[0030] 1. Feeding system

[0031] The feeding system is mainly used to transport solid waste to the incineration system. In order to ensure the smooth combustion of solid waste, it is necessary to add fuel to the solid waste before the solid waste enters the incineration system. In addition to the bucket elevator 2 at the fuel level and the distribution machine 5 for evenly distributing solid waste and fuel, there is also a silo 1: used to ensure sufficient mixing of solid waste and fuel to prevent waste caused by solid waste and fuel splashing and pollution. In order to facilitate feeding and discharging, the lower end of the bucket elevator 2 is provided with a feed port, and the upper end is provided with a disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com