Centrifugal fan impeller for range hood

A centrifugal fan and range hood technology, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of increased noise, decreased aerodynamic performance of the impeller, flow separation of the blade path, etc., and achieves low impact loss and reduced Swirl flow, effect of reducing air intake loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

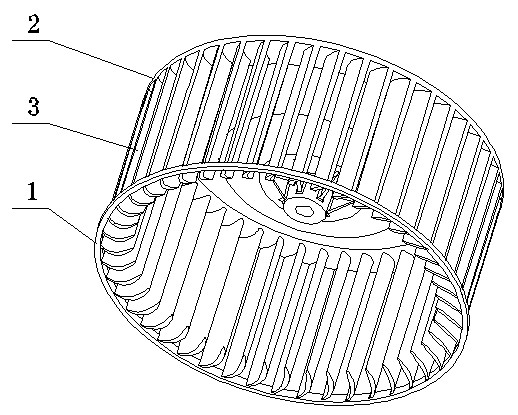

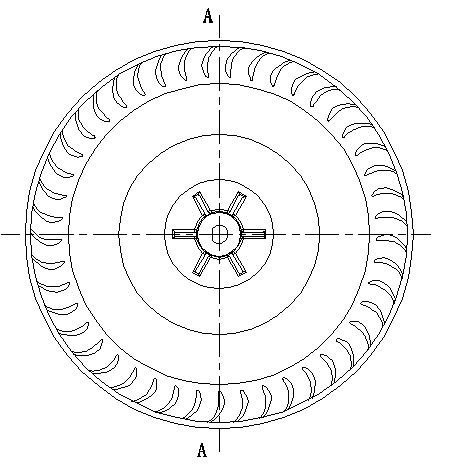

[0021] see Figure 1 to Figure 4 The centrifugal fan impeller of the range hood includes an end ring 1, a wheel disc 2 and a plurality of blades 3, the outer edge of one end of the blade 3 is connected with the inner edge of the end ring 1, and the other end is connected with the outer edge of the wheel 2. The edge parts are connected, and the three are connected into a whole to form a whole.

[0022] The cross-section of the above-mentioned blade 3 is an airfoil structure, and the method for generating the profile line of the airfoil structure adopts the method of superimposing the conventional symmetrical airfoil thickness on the mid-arc, such as Figure 4 shown.

[0023] like Figure 4 As shown, the middle arc BEF of the above-mentioned airfoil structure is composed of two tangent arcs BE and EF, and the tangent point E on it is the maximum camber position of the airfoil structure (that is, the middle arc of the airfoil is at the point E The tangent is parallel to the st...

Embodiment 2

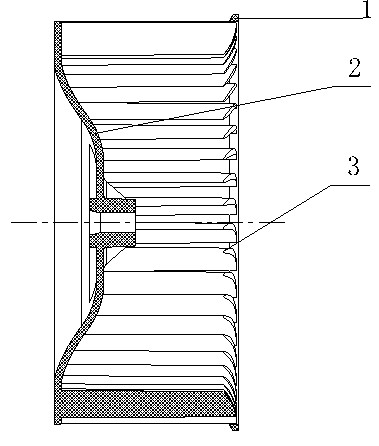

[0030] see Figure 5 to Figure 7 , the impeller of the centrifugal fan of the range hood, its main difference from Example 1 is that the air intake mode of the impeller is double-sided air intake, both ends of the impeller are provided with end rings 1, and there are a number of The blades 3 are equal, and the blades 3 on both sides of the disc 2 are arranged in a staggered manner. Other undescribed parts are the same as in Example 1.

[0031] The actual test shows that, under the same conditions, the noise of the double-inlet impeller with staggered blades on both sides is reduced by about 1dB compared with the double-inlet impeller with aligned arrangement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com