Method and system for reducing temperature locally under coal mine shaft

A local cooling and coal mine technology, which is applied in mine/tunnel ventilation, mining equipment, earthwork drilling, etc., can solve the problems that the cooling machine cannot run stably for a long time, is difficult to meet, and the turbine is damaged by ice particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

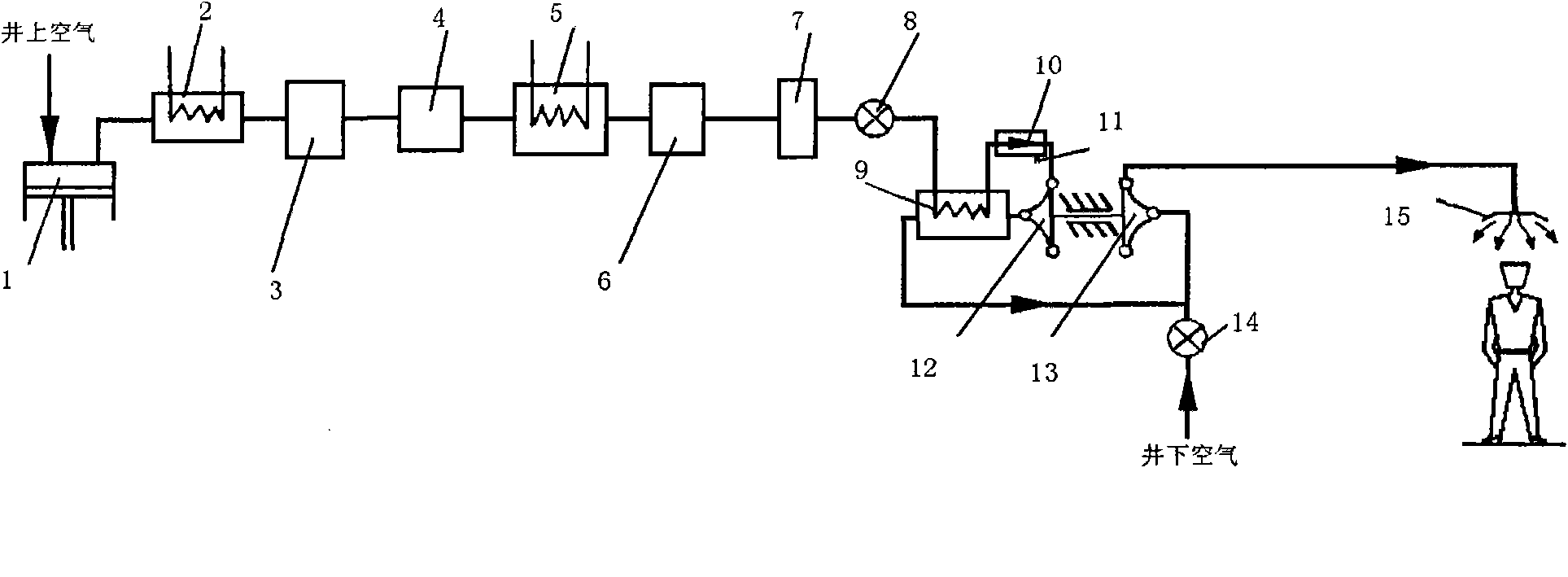

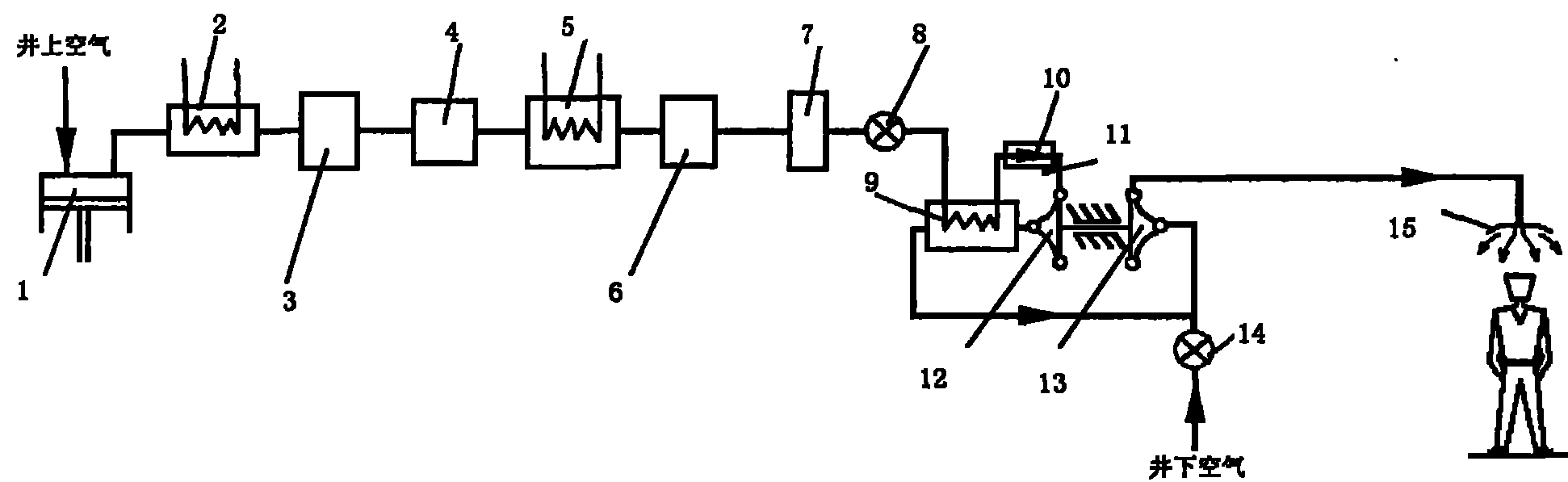

[0014] Attached below figure 1 and one This embodiment further illustrates a method and system for local cooling in coal mines of the present invention.

[0015] like figure 1 As shown, a method and system for local cooling in underground coal mines are composed of an upper part and an underground part.

[0016] The ground part is composed of an air compressor 1 , a cooler 2 , an oil-water separator 3 , a voltage stabilizer 4 , an evaporative condenser 5 and a drying tower 6 . The air on the well is compressed by the air compressor 1 and becomes a high-temperature and high-pressure gas, which is cooled by the cooling water in the cooler 2 at a constant pressure, and the temperature drops to normal temperature, and then the lubricating oil and moisture in the air are separated by the oil-water separator 3 , after passing through the regulator 4, and then through the evaporative condenser 5 and the drying tower 6 to remove water vapor in the air.

[0017] The downhole part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com