Guide ring overwelding seam large-cylinder bottom double-telescopic upright column

A technology of guide ring and cylinder bottom, which is applied in pillars/supports, mining equipment, earthwork drilling and mining, etc. It can solve the problems of small and difficult thin coal seam supports, insufficient expansion and contraction ratio, and influence on support efficiency, so as to achieve optimal force and reliability The effect of improving and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

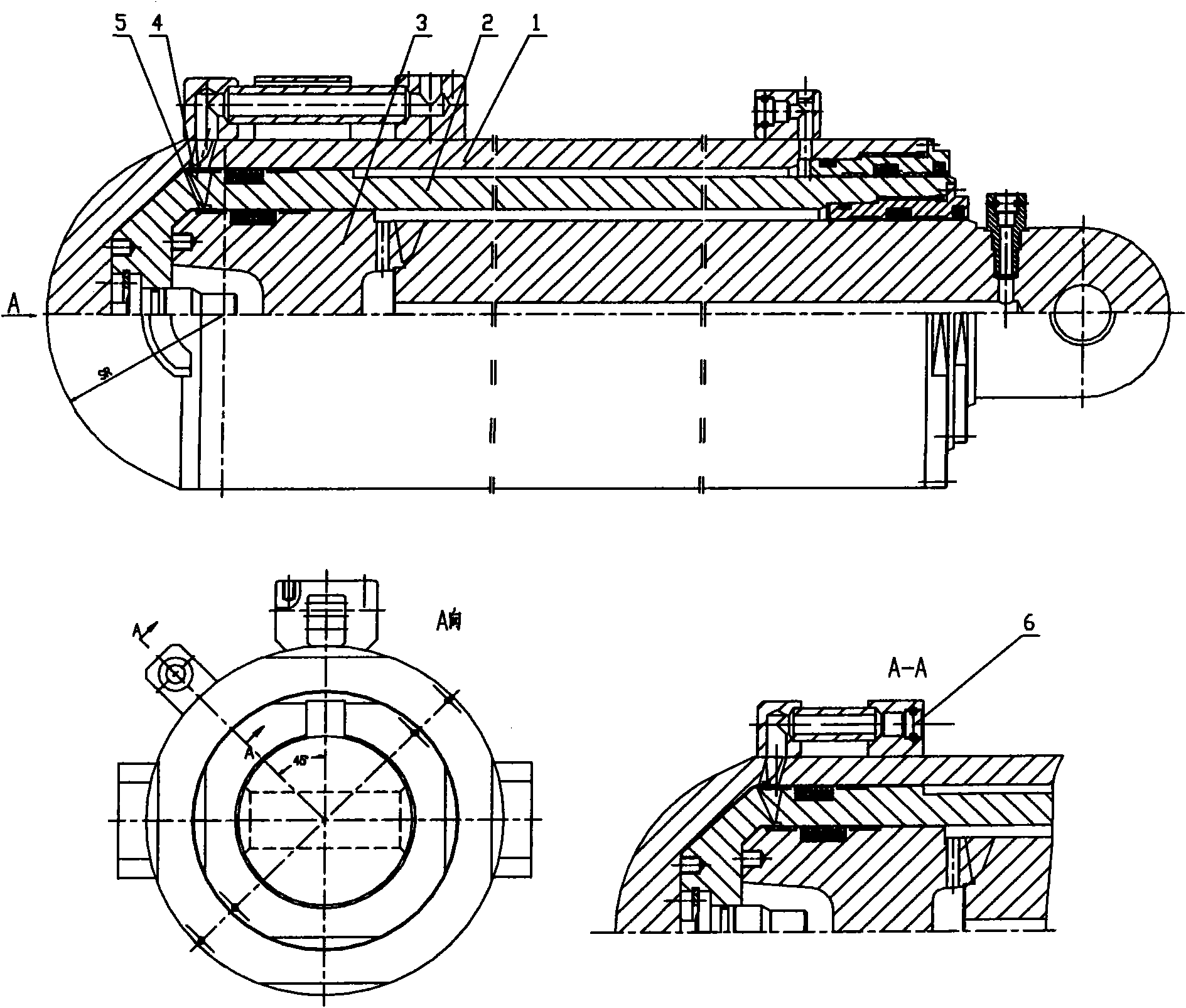

[0014] see figure 1 Shown: a double telescopic column at the bottom of a large cylinder with a guide ring passing through the weld seam, which is composed of the outer cylinder 1, the middle cylinder 2 and the live column 3 as the main force-bearing rods. The guide ring 4 is installed on the middle cylinder and the live column is equipped with Guide ring 5. The inside of the outer cylinder bottom is made hollow, and the middle cylinder bottom is placed in its cavity to the maximum extent; at the same time, the live column bottom is placed in the middle cylinder bottom to the maximum extent, so that the three have a greater degree of overlap. Set the bypass safety valve interface 6 within the range of 40°-45° beside the outer cylinder to install the safety valve.

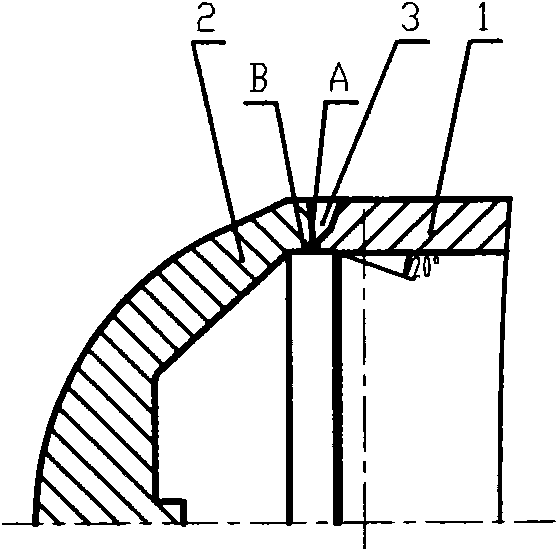

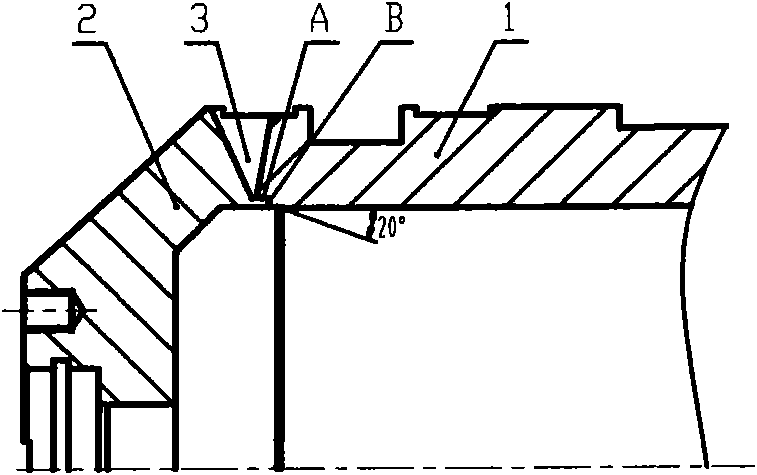

[0015] figure 2 Shown is figure 1 The structure of the guide ring passing through the cylinder bottom and the cylinder barrel weld of the middle and foreign cylinders: the outer cylinder bottom is machined with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com