Novel die-compounding and distributing system and method for producing concrete pile

A technology of concrete pile and material distribution system, which is applied in the direction of ceramic forming machines and manufacturing tools, can solve the problems of affecting product quality, uneven distribution, high production cost, etc., and achieve the goal of eliminating high-intensity labor, reducing frequent replacement, and improving sanitary conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

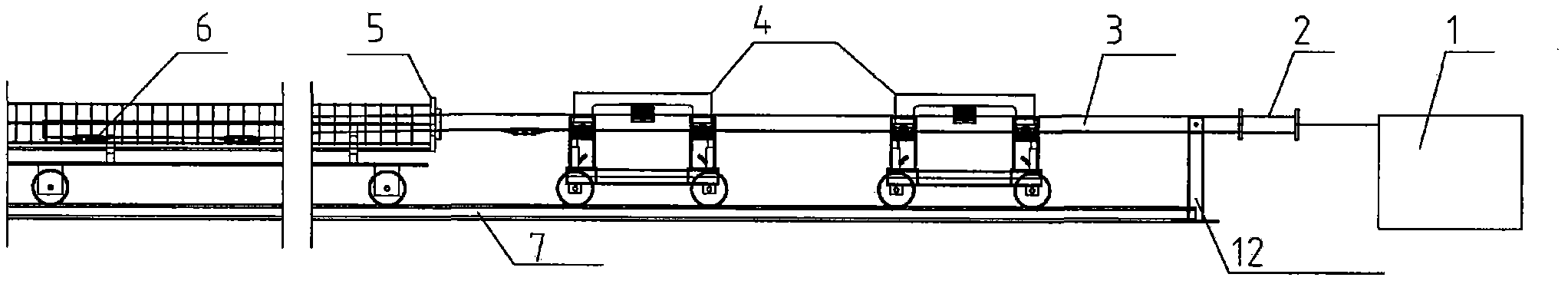

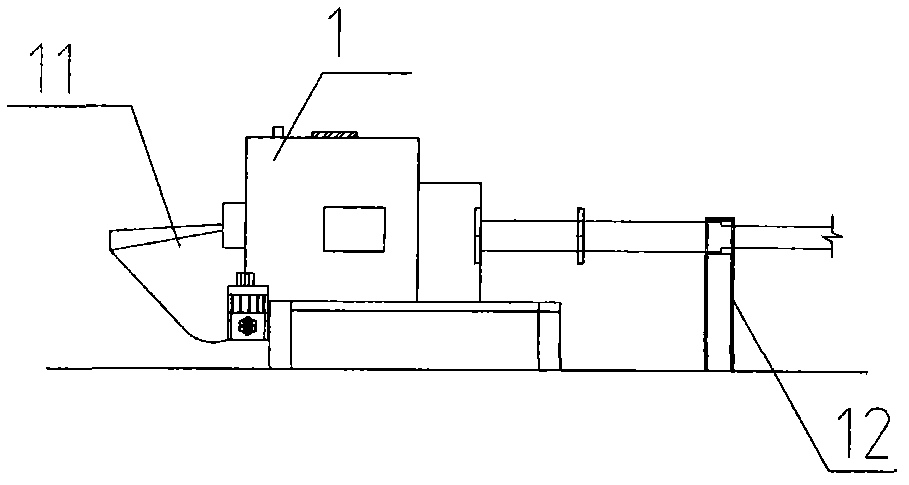

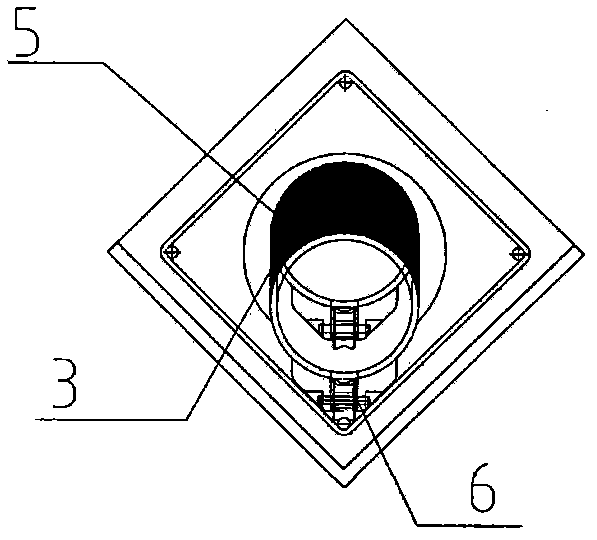

[0025] see figure 1 , a new type of material distribution system, including a concrete pump 1, the concrete pump 1 is connected to a horizontal feeding pipe 3 through a connecting pipe 2, the lower part of the feeding pipe 3 is provided with a moving block 4 for support, and the feeding pipe 3 penetrates into the steel of the concrete pile Inside the mold 5 , the end of the feeding pipe 3 is provided with a sliding shoe 6 that can slide on the prestressed tendons in the steel mold 5 , and the concrete pump 1 , moving block 4 , and steel mold 5 are arranged on the same horizontal track 7 . A steel pipe fixed support frame 12 is provided at the joint between the feeding pipe 3 and the concrete pump 1 .

[0026] Sliding shoe 6 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com