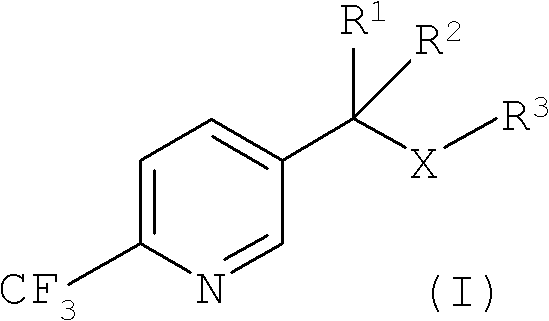

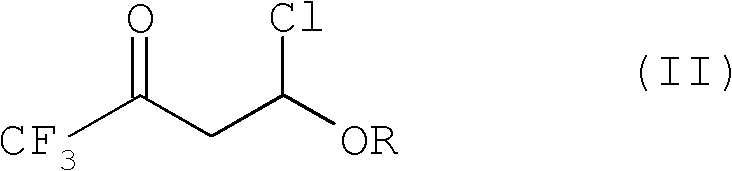

Improved process for the preparation of 2-trifluoromethyl-5-(1-substituted)alkylpyridines

A technology of alkylpyridine and trifluoromethyl, applied in the field of preparation of 2-trifluoromethyl-5-alkylpyridine, can solve the problems of expensive and unstable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Example 1: Preparation of 5-(1-methylthio)ethyl-2-(trifluoromethyl)pyridine

[0089]

[0090] Step 1. Preparation of 1-(3-methylthiobut-1-enyl)pyrrolidine

[0091]

[0092] A dry 5000 milliliter (mL) round bottom flask equipped with a mechanical stirrer, nitrogen inlet, addition funnel, and thermometer was charged with 591 g (4.27 moles) of anhydrous potassium carbonate pellets and 1428 mL (17.1 moles) of anhydrous pyrrolidine. The mixture was stirred under an atmosphere of nitrogen and cooled to 4°C with an ice bath before 1050 mL (8.9 moles) of 3-methyl-thiobutyraldehyde was added at a rate to keep the temperature below 10°C. Once the addition was complete, the cooling bath was removed and the reaction mixture was allowed to reach room temperature. The reaction contents were then filtered through a sintered glass filter funnel to remove solids, which were washed with 200 mL of anhydrous diethyl ether. The filtrate was concentrated in vacuo on a rotary evaporat...

Embodiment 2

[0096] Example 2: Alternative preparation of 5-(1-methylthio)ethyl-2-(trifluoromethyl)pyridine

[0097]

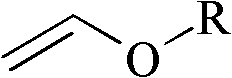

[0098]Charge 240 mL of toluene into a 500 mL jacketed reactor equipped with a circulating bath (containing Syltherm 800), mechanical stirring, dry ice / acetone condenser, and thermowell (with digital monitoring), and then add 43.3 g (0.6 mol) ethyl vinyl ether (EVE). The reaction mixture was cooled to 0 °C, and then a 1 / 4" Teflon line was placed subsurface in the reaction mixture. Trifluoroacetyl chloride (TFAC) was bubbled through the Teflon line for 1 hour. Fluoroethylene resin tube until 95.3 g (0.72 moles) of trifluoroacetyl chloride reagent has been added. During the addition of TFAC, the internal reaction temperature rose from 2°C to 6°C. The circulating bath temperature was then set at 20°C, The reaction mixture was warmed to the circulating bath set point and stirred for an additional 20 minutes. At this point, GC analysis showed the presence of about 4% (GC rel...

Embodiment 3

[0103] Example 3: Alternative preparation of 5-(1-methylthio)ethyl-2-(trifluoromethyl)pyridine

[0104]

[0105] A 2-liter three-neck round bottom flask equipped with mechanical stirring, nitrogen blanket, and temperature probe was charged with 152.0 g (1.10 moles) of solid potassium carbonate, followed by ~1 liter of toluene. To this mixture was added 71.1 g (1.00 moles) of pyrrolidine. The reaction mixture was cooled in an ice-water bath, then 118.20 g (1.00 mole) of 3-methylthiobutanal was added continuously via an addition funnel over 1 hour and 16 minutes. The rate of aldehyde addition was adjusted to keep the internal reaction temperature below ~10°C. The ice-water bath was removed and the reaction mixture was allowed to warm to ambient temperature and stirred for an additional 3 hours 30 minutes. At this point, GC analysis indicated the presence of ~0.4% (relative area) of starting 3-methylthiobutyraldehyde. The reaction mixture was suction filtered, and the filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com