Thermostat valve plug

A technology of temperature control valves and water outlet valves, applied in valve details, multi-way valves, valve devices, etc., can solve problems such as frostbite, failure to show the function of flow adjustment, burns, etc., and achieve the effect of simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

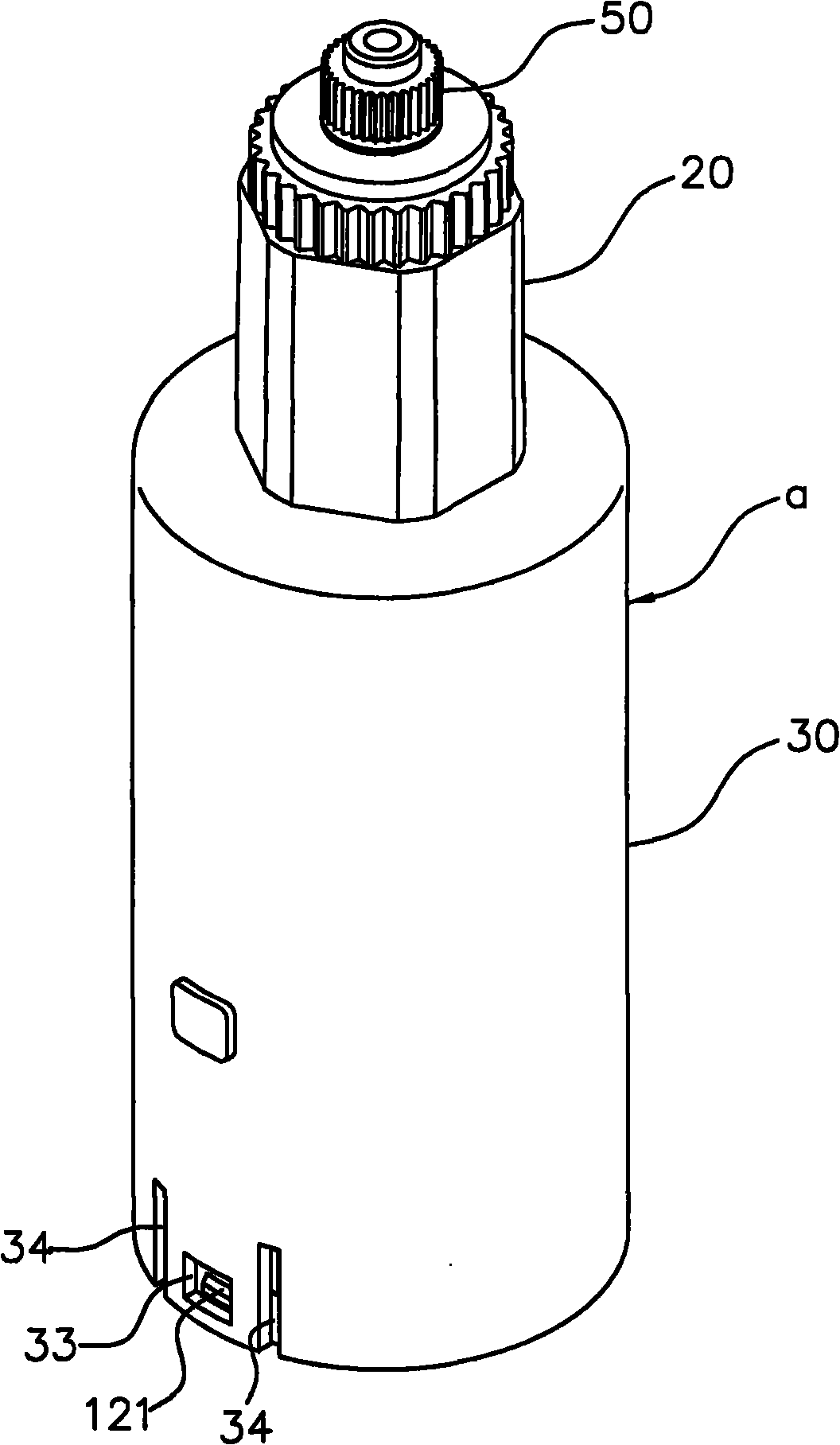

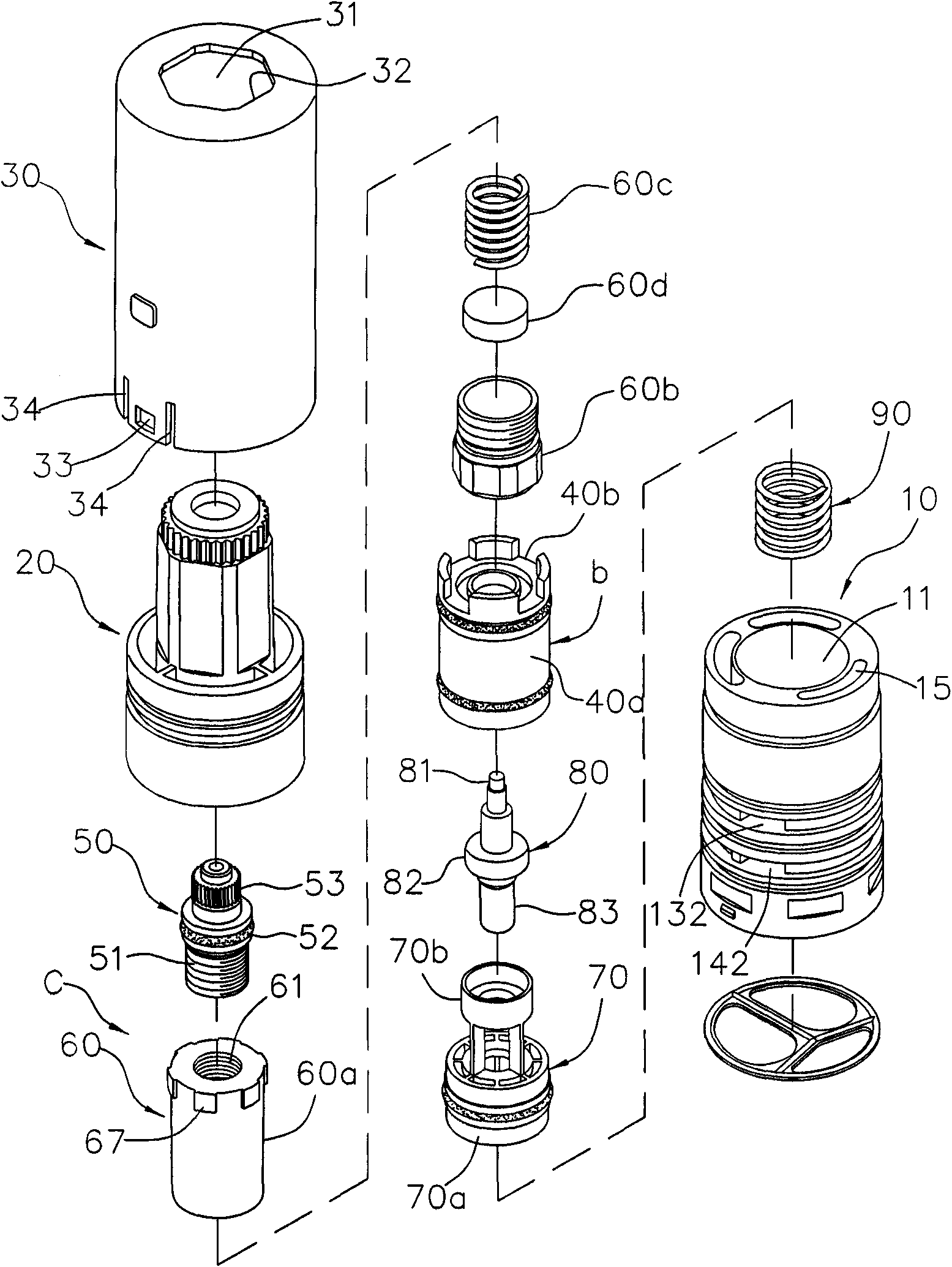

[0034] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. Such as Figures 1 to 3 , The present invention provides a preferred embodiment of a temperature control valve core, which mainly includes a housing part a, a water outlet valve seat b and a control assembly c; the following will describe the above components separately.

[0035] Regarding the housing part a, it also includes a lower housing 10, an upper housing 20 sealed at the top of the lower housing 10, and a housing sealed outside the lower housing 10 and part of the upper housing 20 Body 30; an accommodating space is provided inside the housing part a; wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com