Multilayer gravel packing method and tool

A technology of gravel filling and tools, which is applied in the field of one-time multi-layer gravel filling methods and tools, can solve the problems of slow sand control operation speed, long operation cycle, and high cost, and achieve the effects of saving operation time, short operation cycle, and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

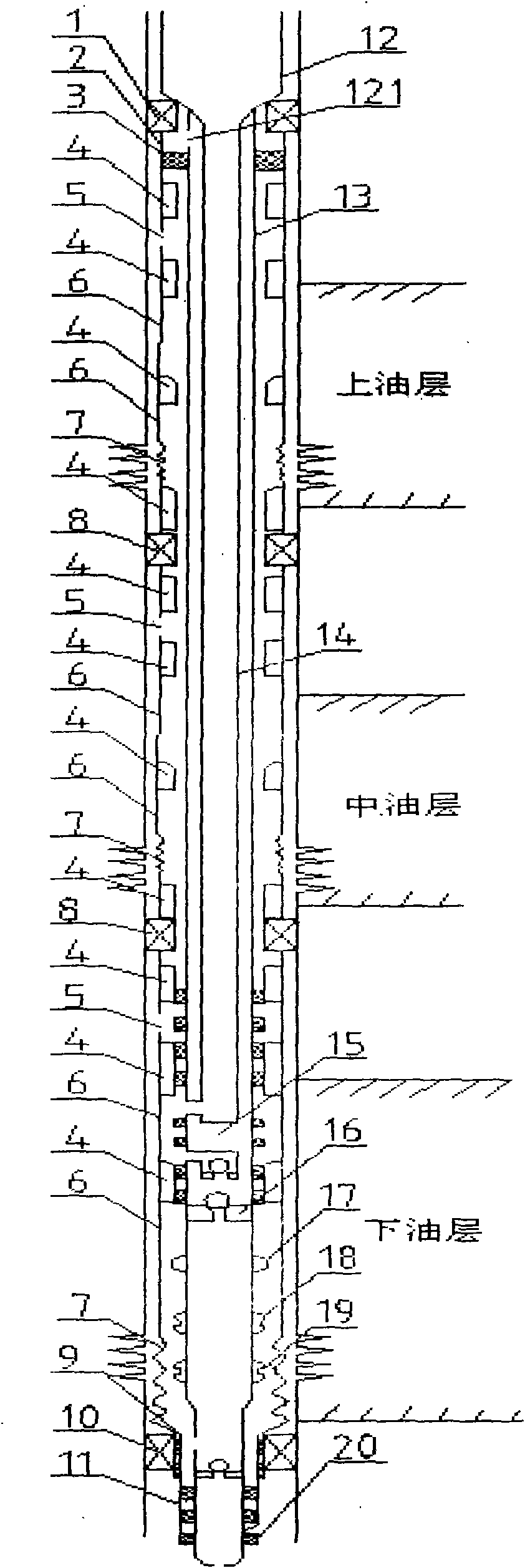

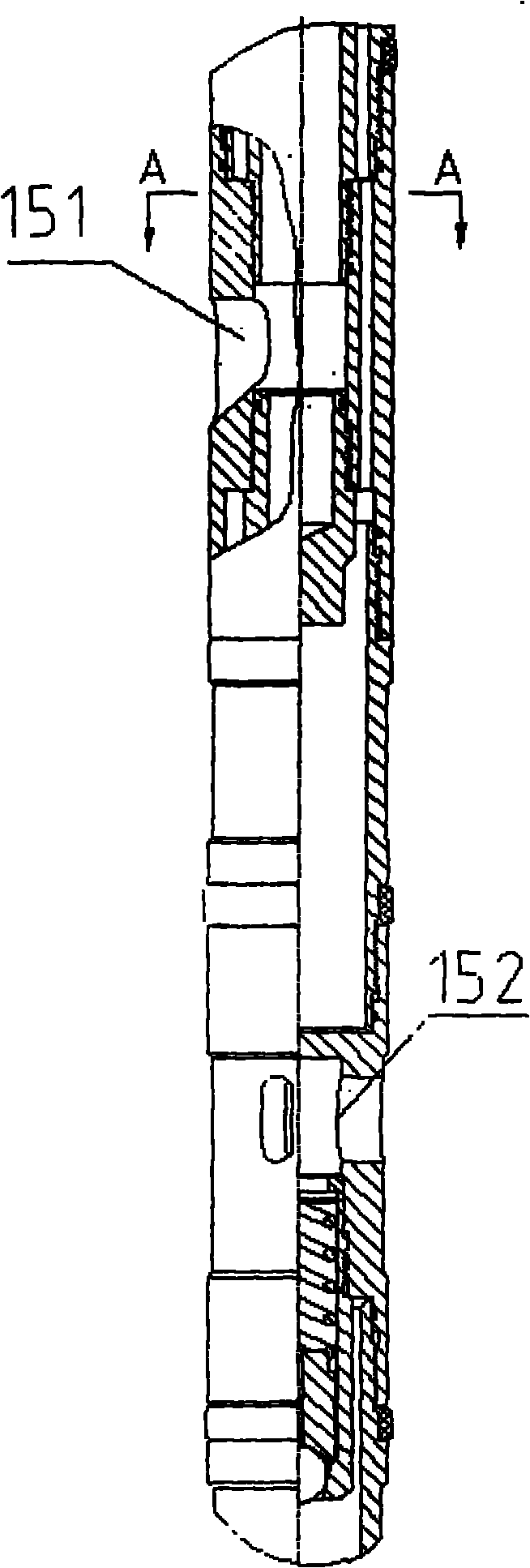

[0025] A one-time multi-layer gravel filling method, taking the filling of three layers as an example, including step A: go down into the gravel filling

[0026]Filling tool, step B: packer setting and seal inspection and step C: formation gravel packing. The A step, B step and C step are carried out in sequence. Step A is: run in a multi-layer gravel packing tool, which can realize reverse circulation operation during the lowering process, and ensure that the multi-layer gravel packing tool is automatically filled during the lowering process; b) insert the positioning seal 9 and the automatic guiding guide shoe 11 are inserted into the sand settling packer 10, and the multi-layer gravel packing tool is lowered into place by lifting the load display; the B step: c) the oil pipe is pressed to 10-15MPa, and the top seal is set. Spacer 1; pressurize 6-8MPa from the casing, and check that the top packer 1 is seated and qualified; pressurize 9-11MPa from the casing or rotate the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com