Sludge dewatering process combining physical and chemical methods

A chemical method and sludge dewatering technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of low efficiency, large investment and high operating cost, and achieve excellent technical effect, firm structure and good modification effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

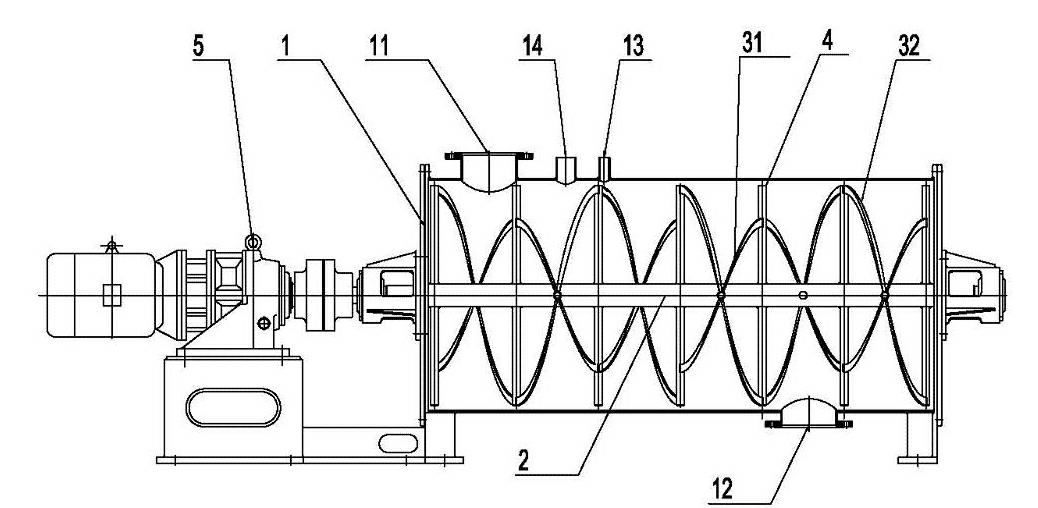

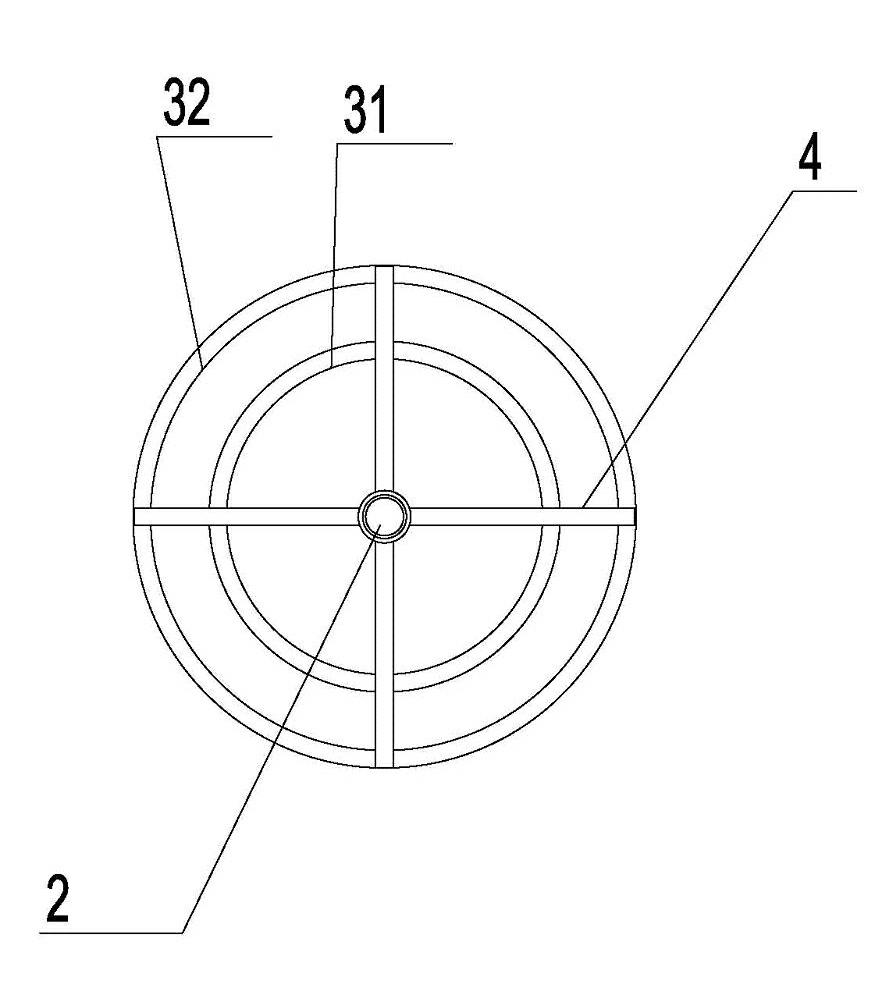

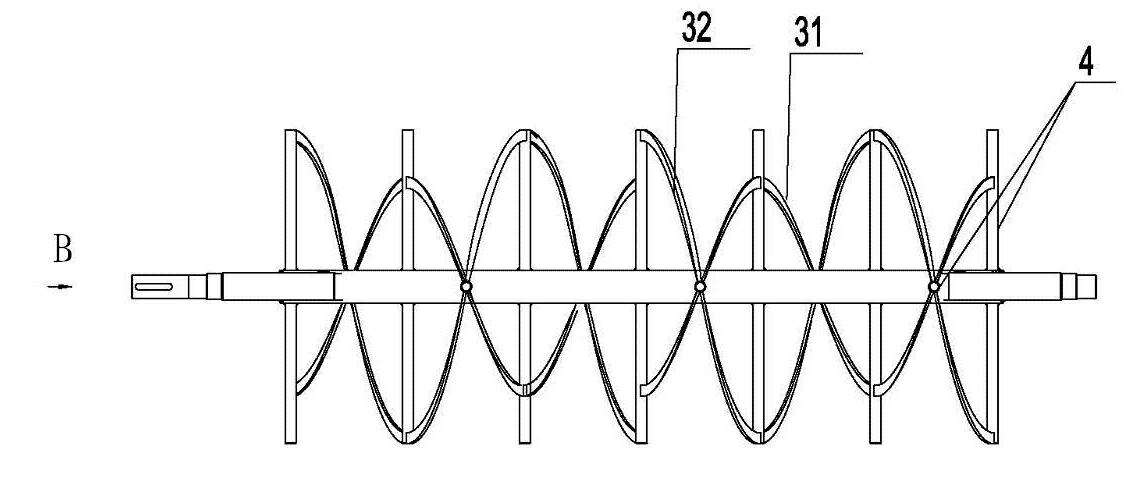

[0045] Example 1: Such as figure 1 , 2 As shown, a sludge reformer includes a cylindrical tank body 1, the tank body includes a mud inlet 11 and a discharge port 12, a rotating shaft 2 is also arranged in the tank body 1, and the rotating shaft 2 is bearing Undertaken in the tank body 1, the rotating shaft 2 is fixed with a stirring screw 3 through the support rod 4. The stirring screw 3 is in the shape of a spiral ribbon, that is, the stirring screw 3 is in the shape of a ribbon, and the end of the stirring screw 3 is along the support rod. The length direction of the screw is fixed on the support rod, and the two belt surfaces of the stirring screw 3 are the working surfaces. Stirring screw 3 comprises inner stirring screw 31 and outer stirring screw 32, and the helical radius of inner stirring screw 31 is 500mm, and the helical radius of outer stirring screw 32 is 700mm. Outer stirring screw rod 32 comprises two groups, and their ends are aligned axially but do not touc...

Embodiment 2

[0048] Embodiment 2: Different from Example 1, the dehydration aid used is the composition of talcum powder and mica equal in weight ratio, water and talcum powder are by 1.5:1, water and mica 2.5:1, and its add-on is 0.11% of sludge weight. Finally, a sludge cake with a moisture content of 37% was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com