Bactericidal composition containing fluazinam and difenoconazole and application of same

A technology of difenoconazole and its composition, which is applied in the field of pesticides, can solve the problems of increased resistance of harmful bacteria and the decline of the effect of difenoconazole on harmful bacteria, so as to reduce the dosage of drugs and avoid the occurrence of resistance The effect of risk, optimal bacteriostatic and bactericidal dual efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

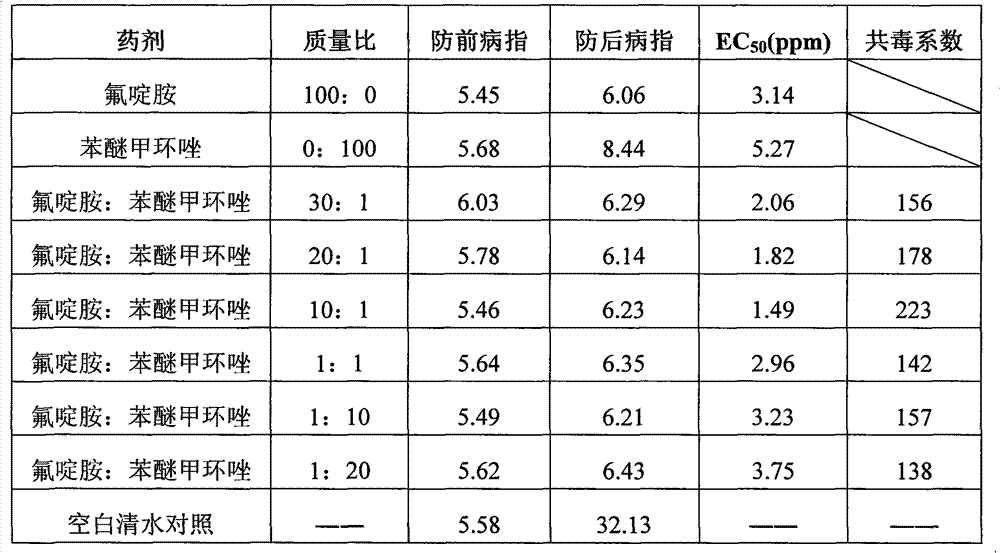

Method used

Image

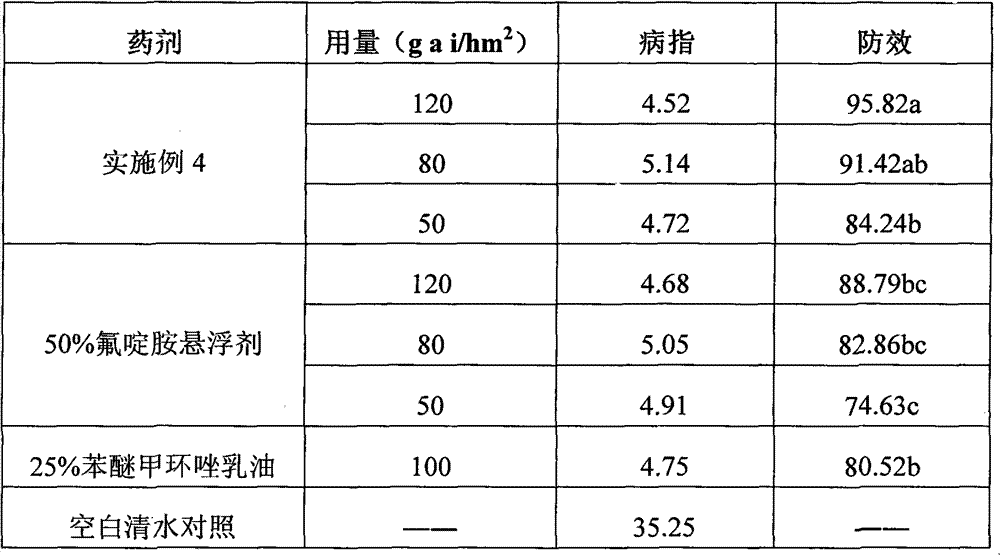

Examples

Embodiment 1

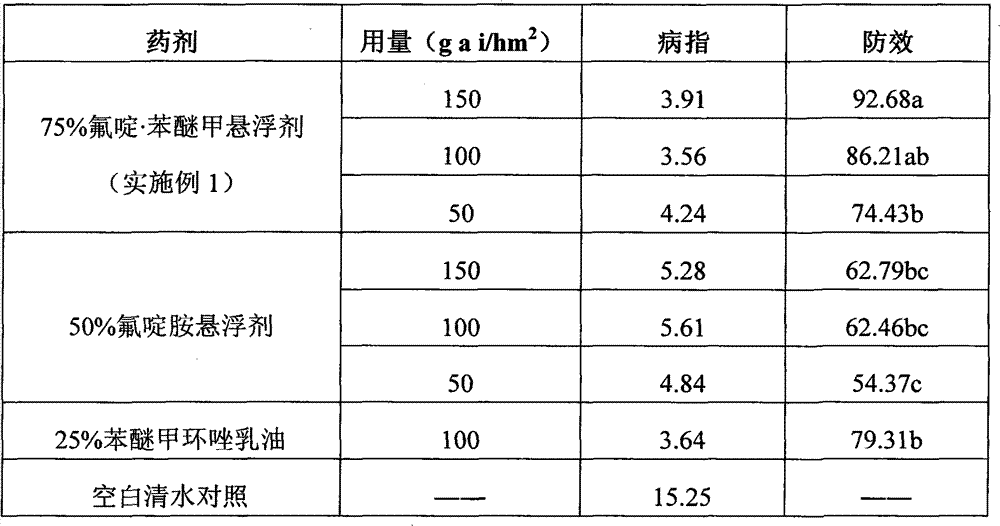

[0016] Example 1: 75% Fluazinam Difenoconazole Suspension Concentrate

[0017] Fluazinam 60kg

[0018] Difenoconazole 15kg

[0019] Styrene phenol formaldehyde resin polyoxyethylene ether phosphate 6kg

[0020] Polysiloxane defoamer 0.2kg

[0021] Xanthan gum 0.3kg

[0022] Water to make up to 100kg

[0023] After the above-mentioned metering components are mixed, they are stirred by a primary sand mill, and after being sanded by a secondary sand mill, they are blended in a preparation kettle, and after the sampling inspection is qualified, the suspension preparation product is obtained by metering and subpackaging.

Embodiment 2

[0024] Example 2: 50% fluazinam·difenoconazole dry suspension concentrate

[0025] Fluazinam 35kg

[0026] Difenoconazole 15kg

[0027] Sodium lignosulfonate 8kg

[0028] Sodium tripolyphosphate 3kg

[0030] Kaolin make up to 100kg

[0031] After uniformly mixing and pulverizing various components, mixing appropriate water, spraying granulation and drying to obtain a dry suspension preparation product.

Embodiment 3

[0032] Embodiment 3: 5% fluazinam difenoconazole suspension seed coating

[0033] Fluazinam 3kg

[0034] Difenoconazole 2kg

[0035] Phosphate emulsifier 5kg

[0036] Bentonite 2kg

[0037] Xanthan gum 0.3kg

[0038] Propylene glycol 5kg

[0039] Polyvinyl alcohol blended modified film-forming agent 0.2kg

[0040] Pigment 0.2kg

[0041] Water to make up to 100kg

[0042] Fully mix the above-mentioned active ingredients, bentonite, phosphate emulsifier and part of water and then sand mill, then add polyvinyl alcohol blended modified film-forming agent, xanthan gum, antifreeze propylene glycol, After the pigment and the remaining amount of water are fully mixed, the suspension seed coating preparation product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com