Composite-rotor brushless double-fed alternating current motor

A brushless double-fed, AC motor technology, applied in asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of complex manufacturing process, large loss of rotor windings, poor modulation effect, etc., and achieves simple structure and improved performance. The effect of price ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] To further illustrate the present invention, the composite rotor brushless doubly-fed AC motor of the present invention will be described in more detail below in conjunction with embodiments.

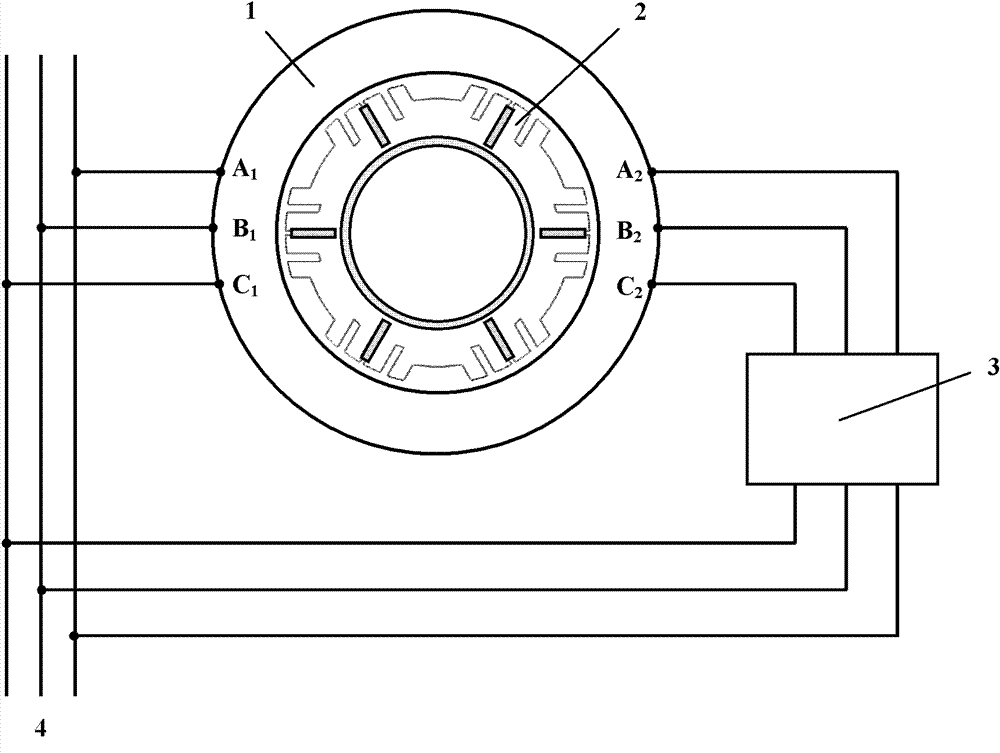

[0023] figure 1 It is a schematic diagram of the composite rotor brushless double-fed AC motor of the present invention, where 1 is the motor stator, 2 is the rotor, 3 is the controller, and 4 is the AC power supply. Two sets of independent symmetrical windings are placed in the core slot of the motor stator 1. The power winding outlet terminals are represented by A1, B1, C1, and the control winding outlet terminals are represented by A2, B2, C2. The connection relationship of the windings is: the outlet terminals A1, B1, and C1 of the power winding are connected to the AC power source 4, and the outlet terminals A2, B2, C2 of the control winding are connected to the AC power source 4 through the controller 3.

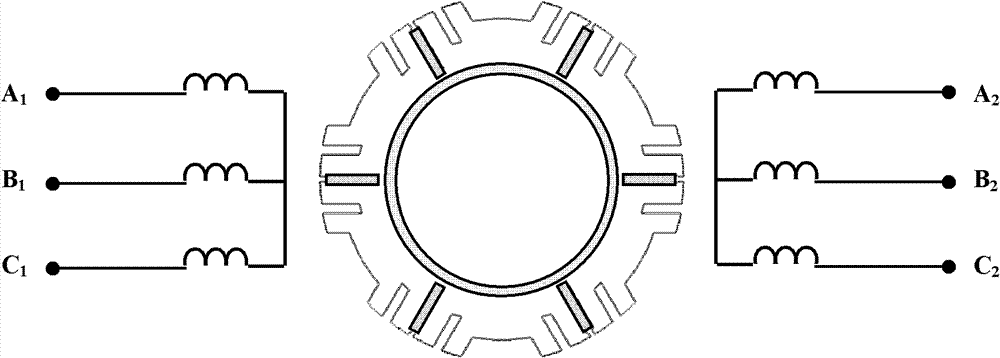

[0024] figure 2 It is a schematic diagram of the stator winding structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com