Preprocessing method using redundancy metal filling for realizing layout density uniformity

A redundant metal and layout density technology, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem of uneven metal line density on the layout, and achieve the effect of global density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] see Figure 5 , an embodiment of the present invention provides a preprocessing method for achieving layout density uniformity by using redundant metal filling, including the following steps:

[0028] Step 1: Set the preset block density lower limit Dl, and the preset allowable density fluctuation value ΔD;

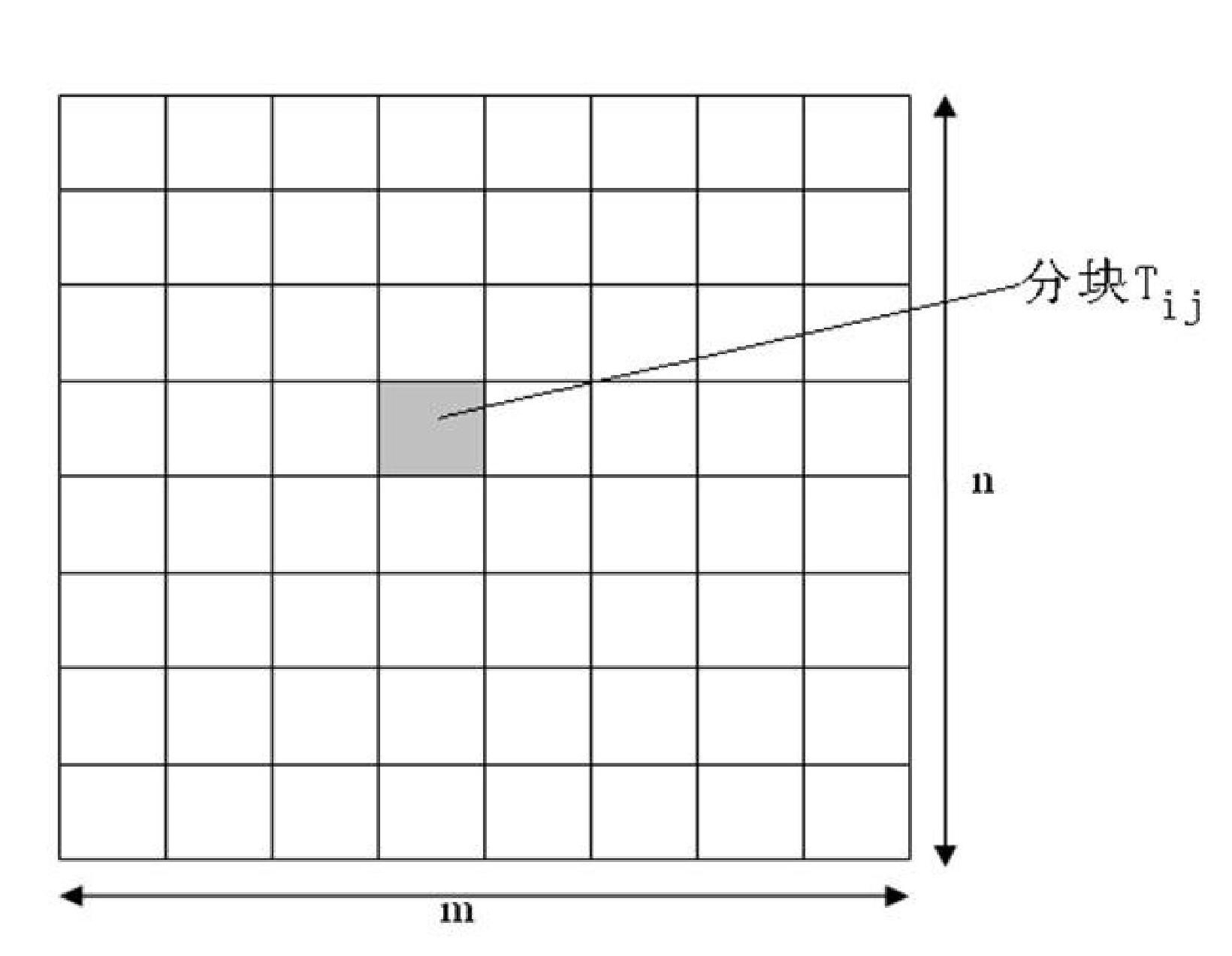

[0029] Step 2: Grid the layout and divide it into m×n small blocks Tij(m, n are all integers greater than 1, 1figure 1 ;

[0030] Step 3: Use the CMP simulation tool to calculate the density of each block, which is recorded as Dij (1<=i<=m, 1<=j<=n);

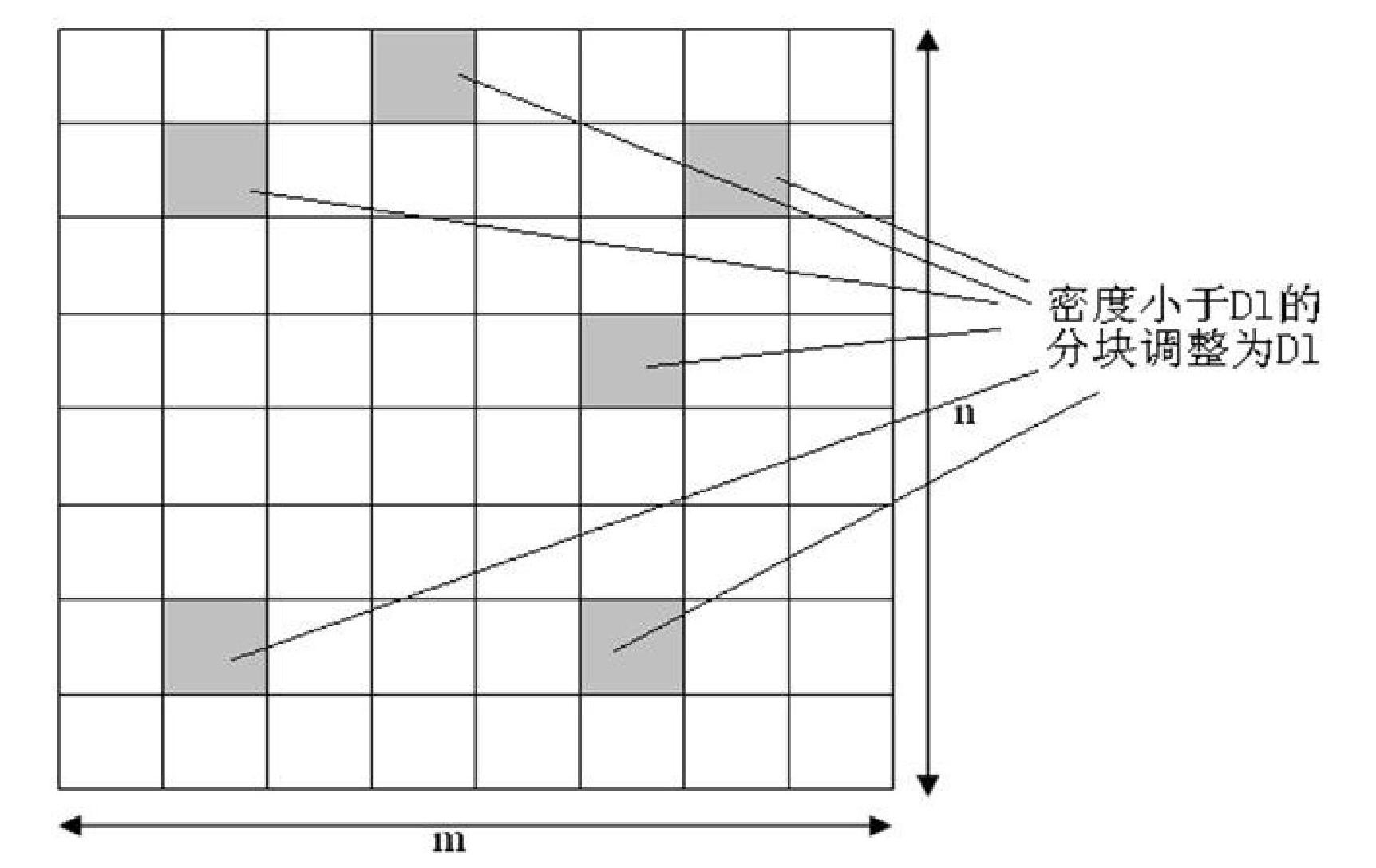

[0031] Step 4: Determine whether there is a block with a density lower than the preset block density lower limit Dl, if so, adjust the block density to Dl, which is recorded as Nij, see figure 2 ;

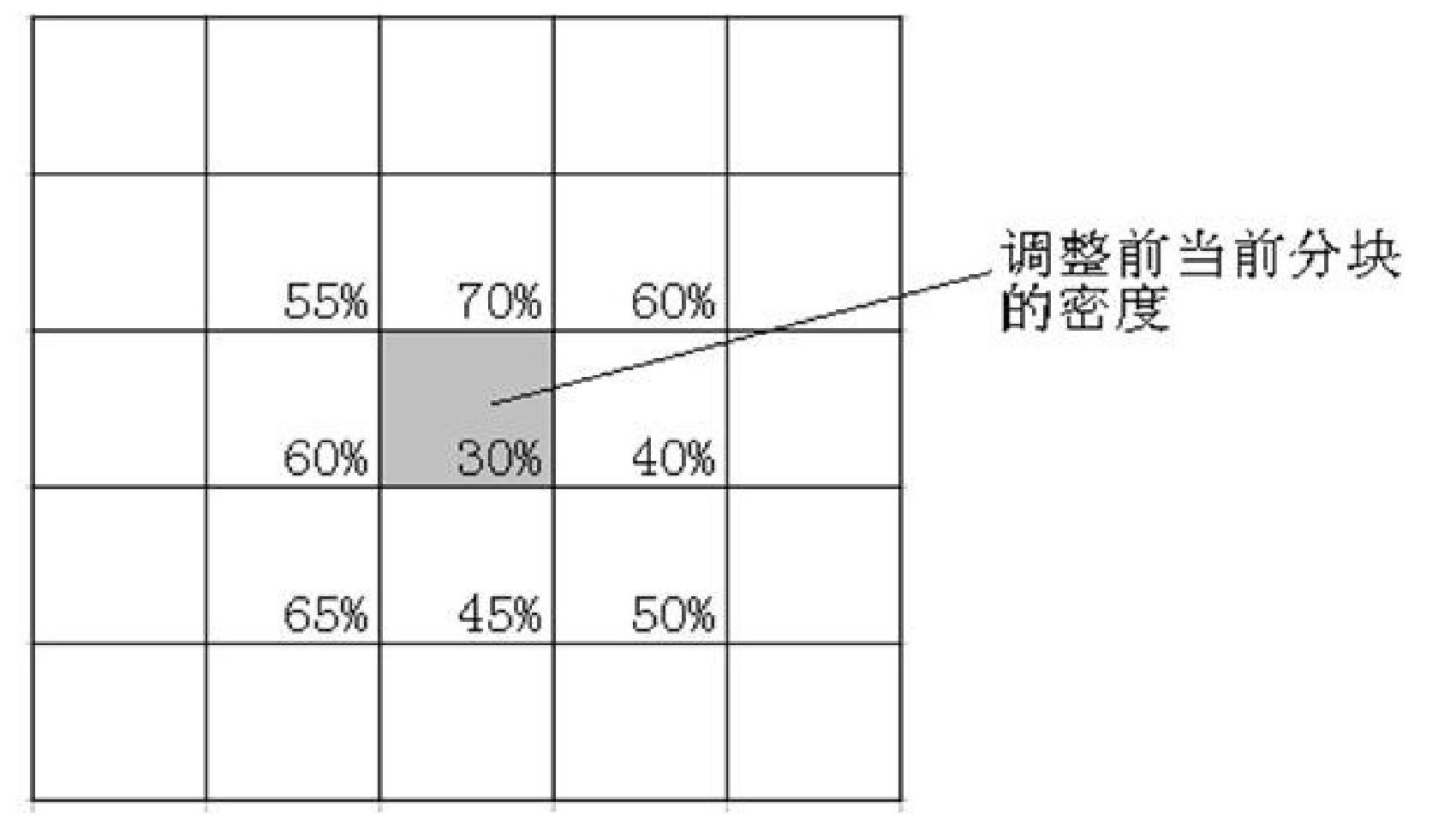

[0032] Step 5: Starting from the first block on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com