Large-aperture gas flow calibration device capable of providing two flow fields

A gas flow and standard device technology, applied in measuring devices, test/calibration devices, liquid/fluid solid measurement, etc., can solve the problems of low accuracy, complexity, cumbersome measurement and calculation, etc., and achieve convenient production and simple structure , suitable for large-scale promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

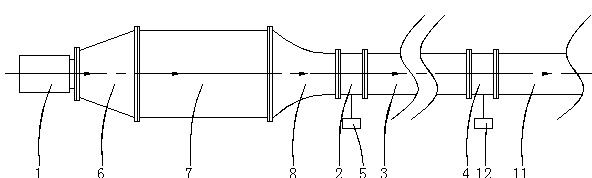

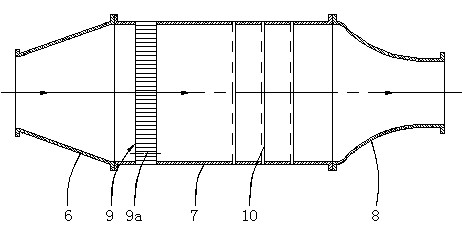

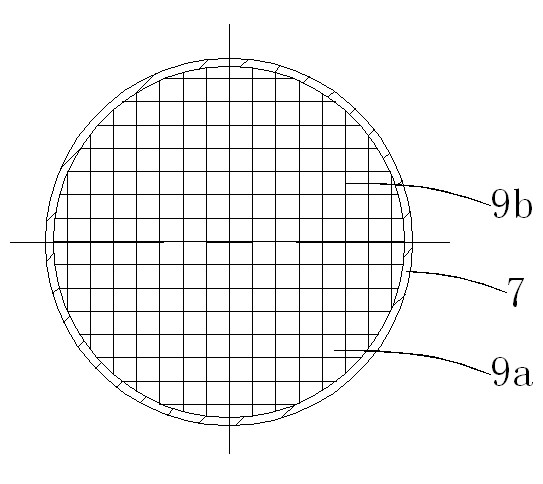

[0022] like Figure 1~3 As shown, the present invention consists of wind source equipment 1, measuring pipe 2, straight pipe 3, meter installation pipe 4, standard speedometer 5, air inlet pipe 6, intermediate pipe 7, air outlet pipe 8, flow straightener 9, rectifier The screen 10 and the pipe 11 are composed of components, wherein the wind source equipment 1 is a fan or a compressor, and other wind source equipment can also be selected according to the actual situation, and is not limited to the fan or compressor. At the outlet end of the wind source device 1, the air inlet pipe 6, the intermediate pipe 7, the air outlet pipe 8, the measuring pipe 2, the straight pipe 3, and the calibration meter are installed in sequence according to the gas flow direction (the direction is shown by the arrow in the figure). The tube 4 and the tube 11, the above-mentioned 7 tubes are all arranged in the same direction, and the center lines of the 7 tubes are on a straight line. The air inle...

Embodiment 2

[0027] like Figure 4~6 It can be seen that in this embodiment, the intermediate pipe 7 is a square pipe, and the air outlet of the air inlet pipe 6 and the air inlet of the air outlet pipe 8 are also adjusted to be square accordingly. The flow straightener 9 in the intermediate pipe 7 is also correspondingly adjusted to a square structure, and the grid 9a of the flow straightener 9 can be a square hole, a regular hexagonal hole, or a circular hole. The rectifying screen 10 in the intermediate pipe 7 is also correspondingly adjusted to a square structure, and the rest of the structure of this embodiment is completely the same as that of Embodiment 1, and will not be repeated here.

[0028] The working principle of the present invention is as follows:

[0029] The wind source device 1 generates gas, the gas first enters the air intake pipe 6, flows in the air intake pipe 6 to form an airflow, and the flow velocity is reduced, and the airflow after the flow velocity is reduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com