Slide plate double-layer sewing device

A double-layer, sewing technology, which is applied in the field of sewing machines, can solve the problems of sliding between leather materials, unqualified sewing products, and leather materials that cannot be sewn together, and achieve the effect of accurate sewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

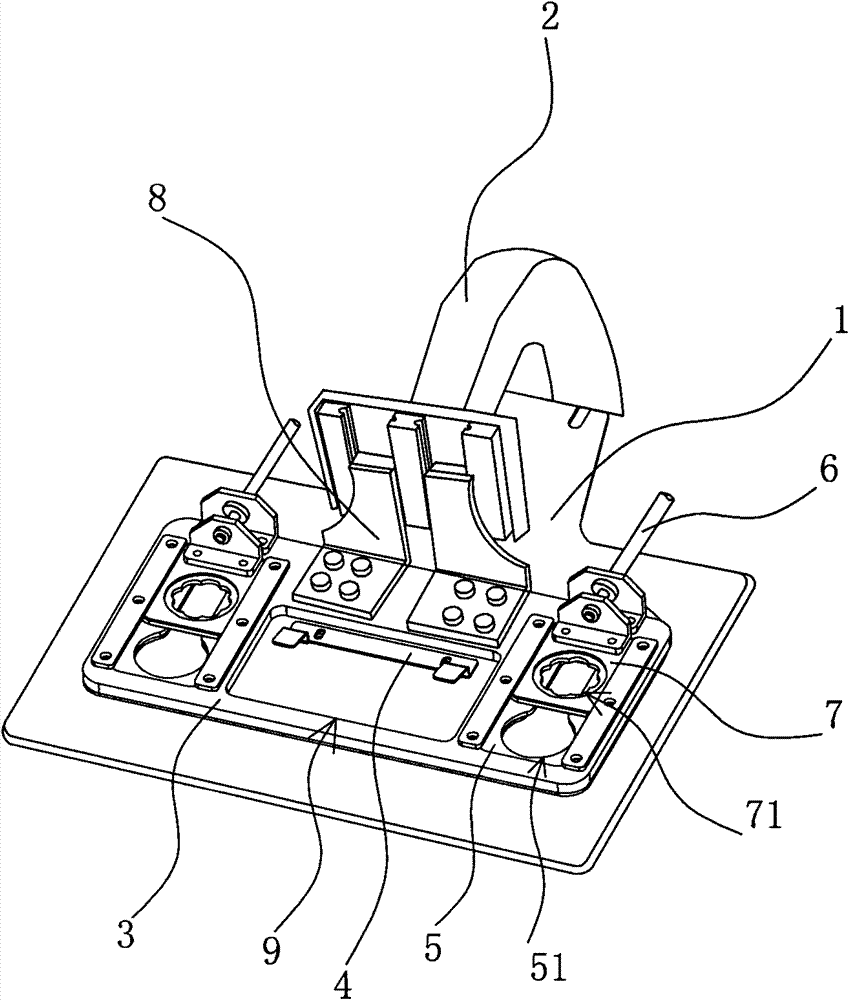

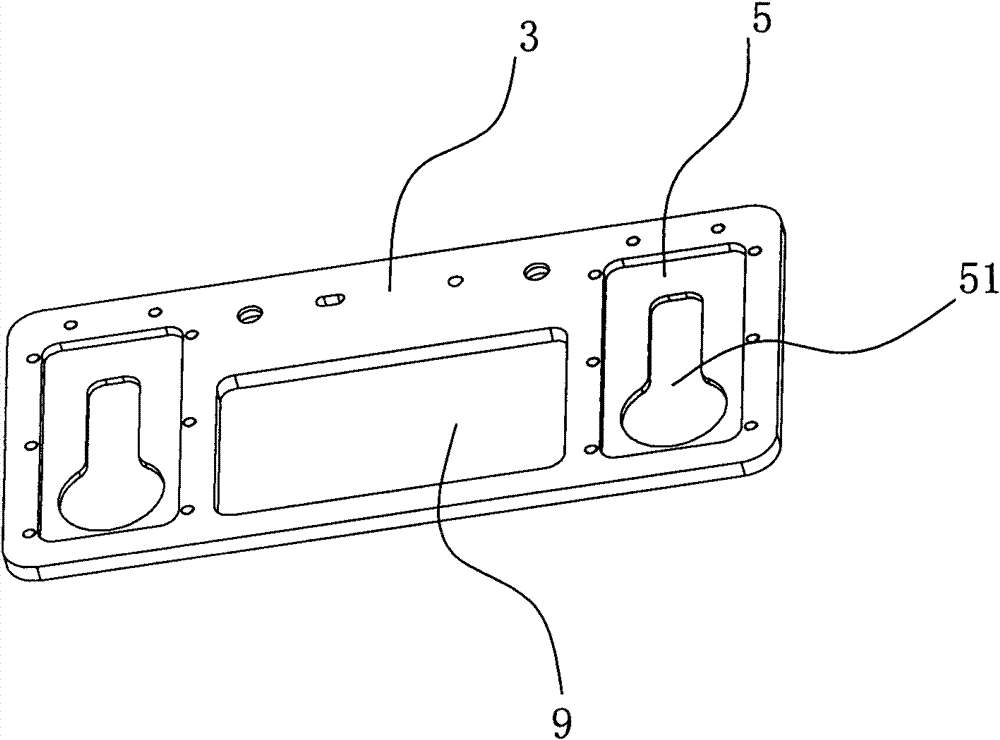

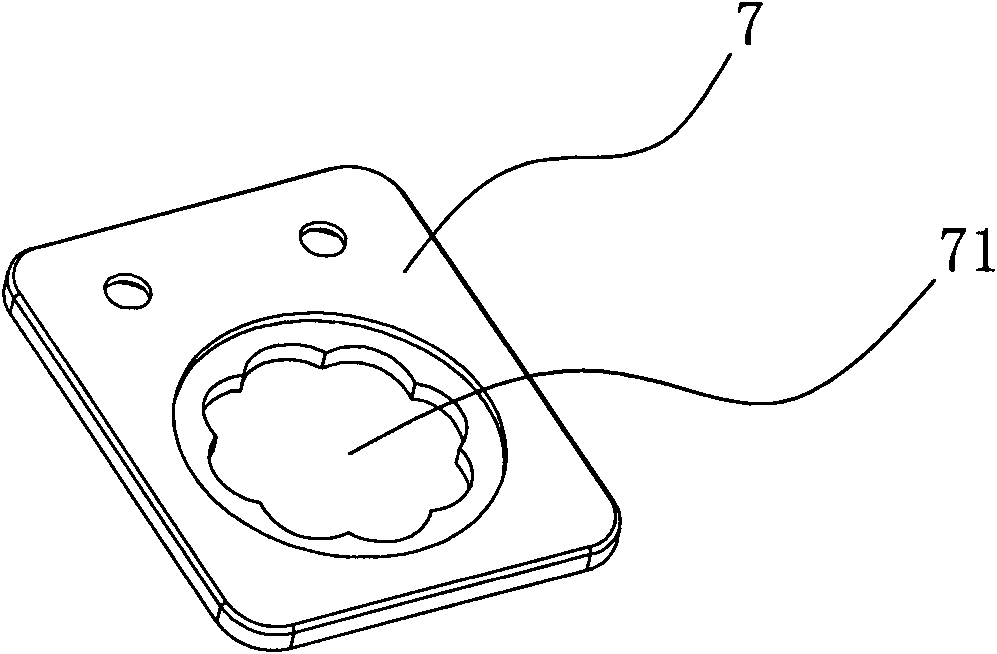

[0017] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-3 :

[0018] Skateboard double-layer sewing device includes a bottom plate 1 and a connecting seat 2 fixedly connected with the moving device of the sewing machine. The connecting seat 2 is connected with a pressing plate 3, and the pressing plate 3 is located directly above the bottom plate 1. It is characterized in that: The pressing plate 3 can move up and down relative to the connecting seat 2, the upper surface of the base plate 1 is fixedly connected with a positioning clamp 4, and the pressing plate 3 is provided with two slots with slideways, and each slot is equipped with a mold hole. A template one 5 of one 51 is provided with a cylinder 6 fixedly connected to the pressing plate 3 directly behind the template one 5, and the piston rod of the cylinder 6 is fixedly connected with a template two 7 with a die hole two 71, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com