Method for preparing actinidia arguta polysaccharides

A technology for kiwifruit and polysaccharide is applied in the field of preparation of extracting kiwifruit polysaccharide, which can solve the problem of inability to extract polysaccharide from kiwifruit, and achieve the effects of low extraction cost, strong operability and high extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

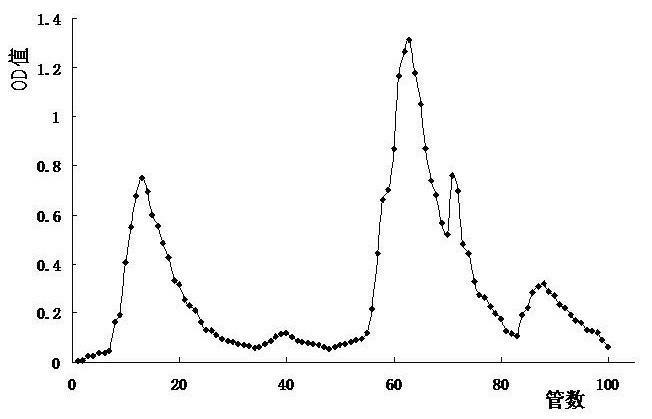

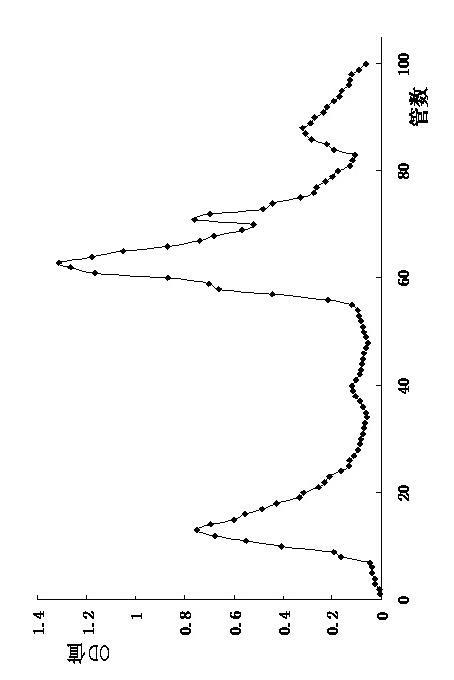

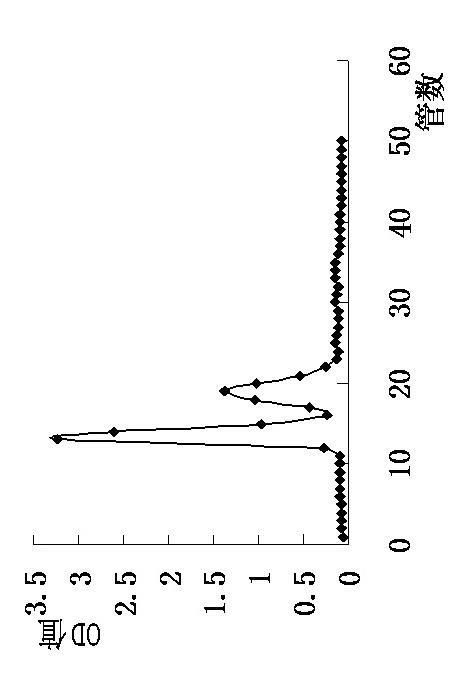

Image

Examples

Embodiment 1

[0026] a. Extraction of crude polysaccharides: wash the fresh kiwi fruit of Jujube jujube, absorb the surface moisture, and crush; add ethanol with a concentration of 80% in a ratio of 1:3, extract in a water bath at 80°C for 0.5h, and centrifuge; precipitate according to the ratio Add distilled water at 1:6, extract in a water bath at 90°C for 3 hours, and centrifuge to obtain a supernatant; the supernatant is concentrated by a rotary evaporator in vacuum; then the concentrate is added to 95% ethanol at a ratio of 1:7 to precipitate for 5 hours , filtered; the filter residue was successively rinsed with absolute ethanol, acetone and anhydrous ether, and filtered to obtain a precipitate; the precipitate was freeze-dried to a constant weight to obtain a crude polysaccharide;

[0027] b. Removal of impurities:

[0028] The first step: degreasing by Soxhlet extraction: at 50°C, Soxhlet extraction with petroleum ether for 5 hours, degreasing the crude polysaccharide in step "a"; ...

Embodiment 2

[0033] a. Extraction of crude polysaccharides: wash the fresh kiwi fruit of Jujube jujube, absorb the surface moisture, and crush; add ethanol with a concentration of 75% in a ratio of 1:4, extract in a water bath at 85°C for 1 hour, and centrifuge; precipitate in a ratio of 1 :5 add distilled water, extract in a water bath at 85° C. for 2 h, centrifuge to obtain a supernatant; the supernatant is concentrated in vacuum with a rotary evaporator; Filtration; the filter residue was successively rinsed with absolute ethanol, acetone and anhydrous ether, and filtered to obtain a precipitate; the precipitate was vacuum-dried for 1 hour, and continued to dry to obtain crude polysaccharide;

[0034] b. Removal of impurities:

[0035] Step 1: Degreasing by Soxhlet extraction: Soxhlet extraction with petroleum ether for 6 hours at 45°C to degrease the crude polysaccharide in step "a";

[0036] The second step: deproteinization by Sevage method: the crude polysaccharide after degreasing...

Embodiment 3

[0040] a. Extraction of crude polysaccharides: wash the fresh kiwi fruit of Jujube jujuba, absorb the surface moisture, and crush; add 85% ethanol in a ratio of 1:2, extract in a water bath at 75°C for 0.7h, and centrifuge; precipitate in a ratio of 1: 7 Add distilled water, extract in a water bath at 95°C for 4 hours, and centrifuge to obtain a supernatant; the supernatant is concentrated in a vacuum using a rotary evaporator; Filtration; the filter residue was rinsed successively with absolute ethanol, acetone and anhydrous ether, and a precipitate was obtained by filtration; the precipitate was freeze-dried to a constant weight to obtain a crude polysaccharide;

[0041] b. Removal of impurities:

[0042] Step 1: Degreasing by Soxhlet extraction: Soxhlet extraction with petroleum ether for 4.5 hours at 55°C to degrease the crude polysaccharide in step "a";

[0043] Second step: Sevage method deproteinization: the crude polysaccharide after defatting is made into the aqueous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com