Lifting device and stage structure using same

A lifting device and stage technology, applied in the direction of lifting devices, theaters, etc., can solve the problems of large installation size, inability to guarantee the safety of actors, unstable lifting and other problems, and achieve the effect of reducing the installation size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below with reference to the drawings.

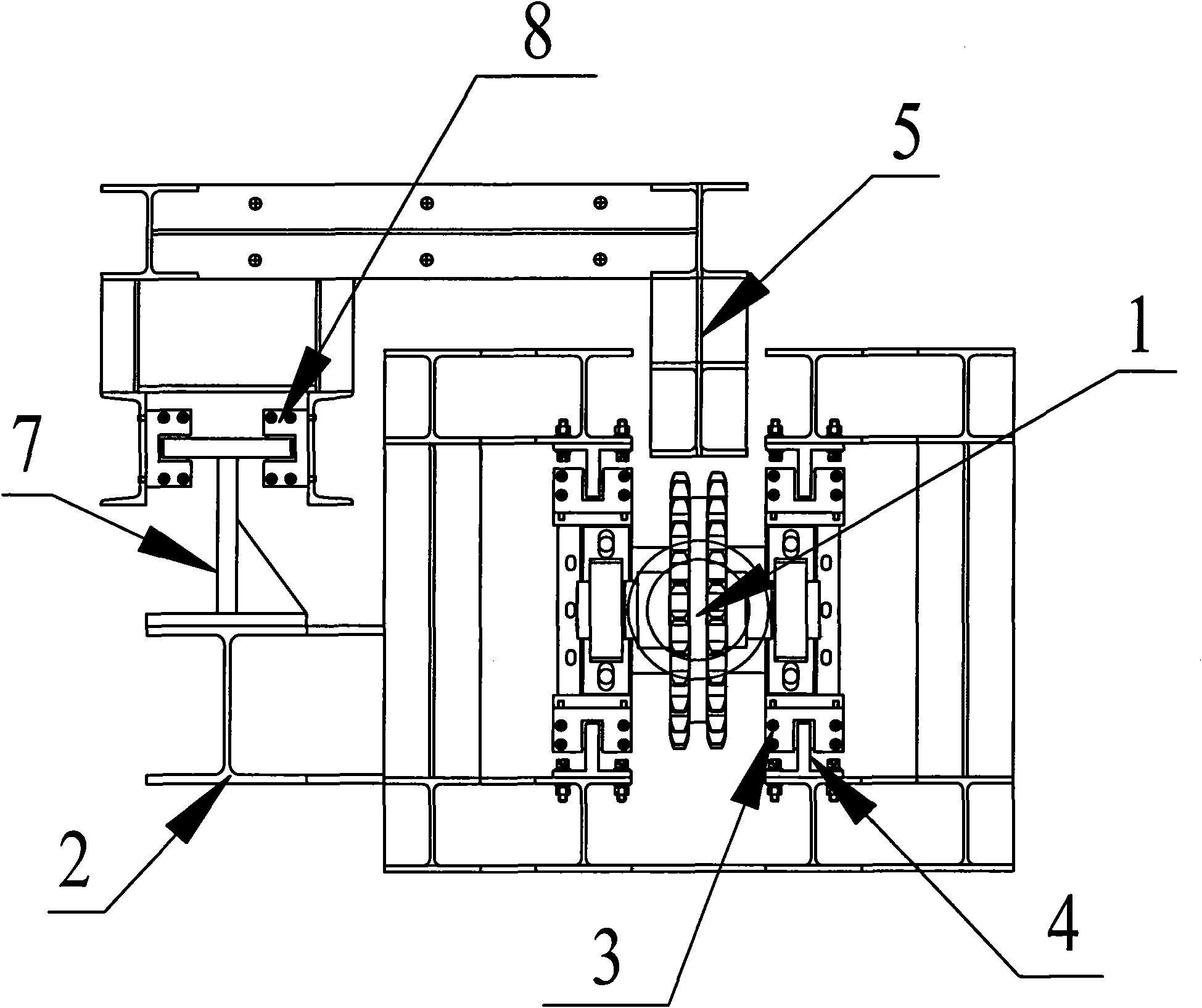

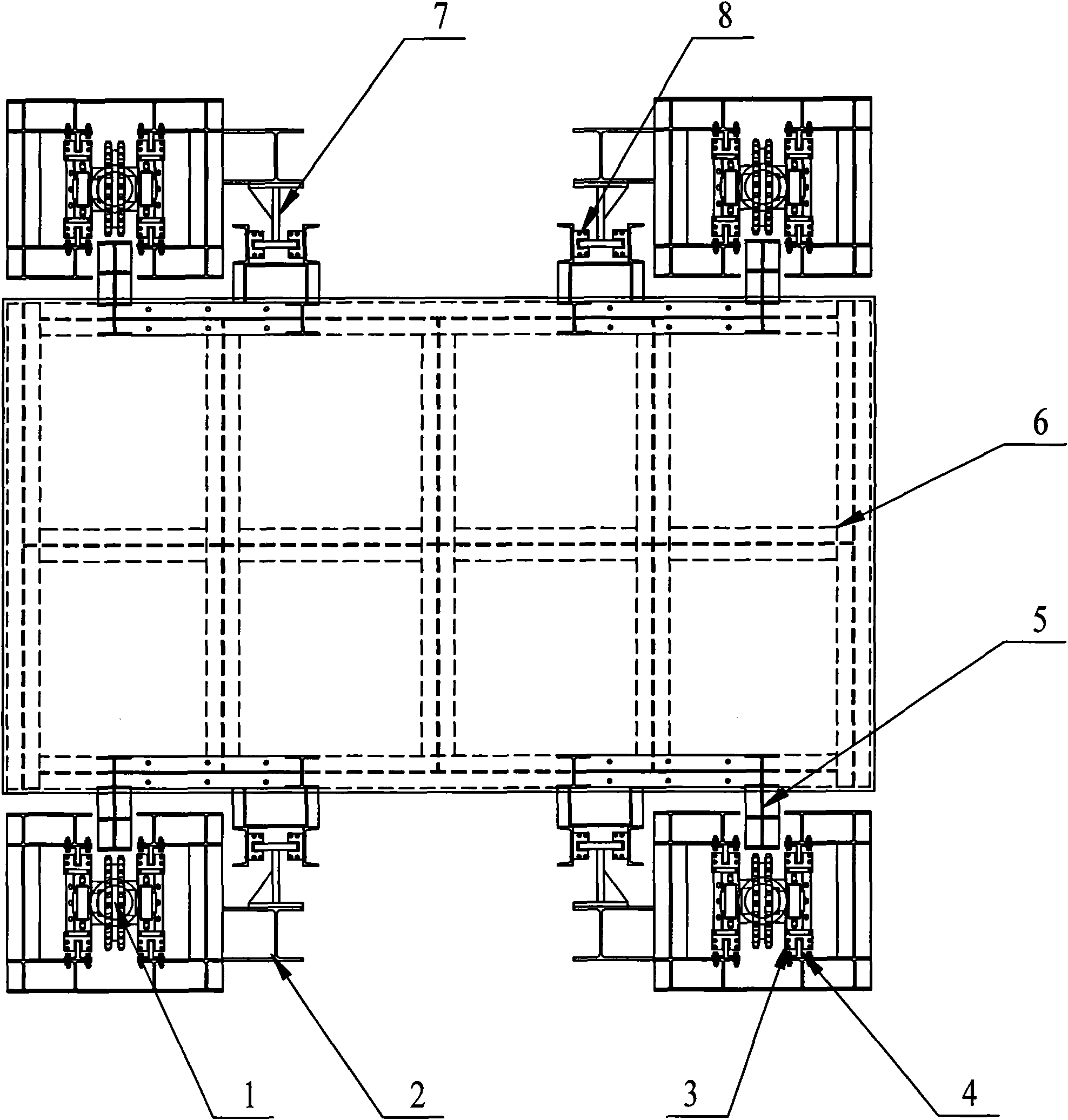

[0024] The structure of the lifting device for driving the working platform up and down according to the preferred embodiment of the present invention is shown as follows: figure 1 shown, see also image 3 , the lifting device includes a fixed frame 5 for connecting the working platform 6, and also includes a guide frame 2 and a sprocket assembly 1. The work platform 6 can be a stage, or a platform for other operations.

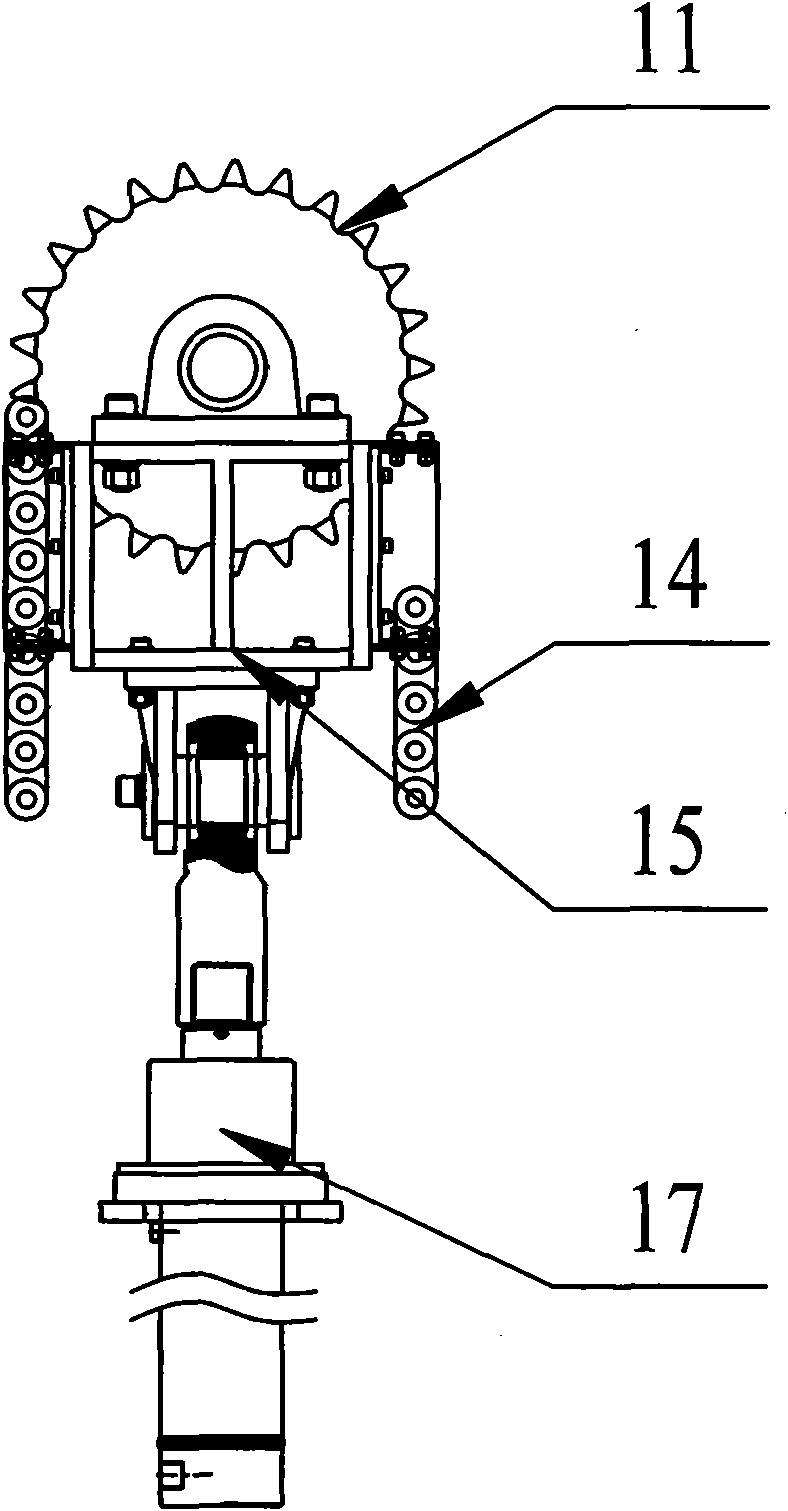

[0025] Among them, such as figure 2 As shown, the sprocket assembly 1 includes a sprocket 11 and a chain 14 wound on the sprocket 11 , one end of the chain 14 is fixedly connected to the fixing frame 5 , and the other end is fixedly connected to the guide frame 2 . The sprocket 11 is arranged on the guide frame 2 so as to slide and rotate relatively.

[0026] In this embodiment, the lifting device further includes a driving device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com