Method for acquiring reference product yield of new product on production line

A new product and production line technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as low product yield, high defect density, and inability to accurately predict new product benchmark product yields, etc. The effect of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the object, technical solution, and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

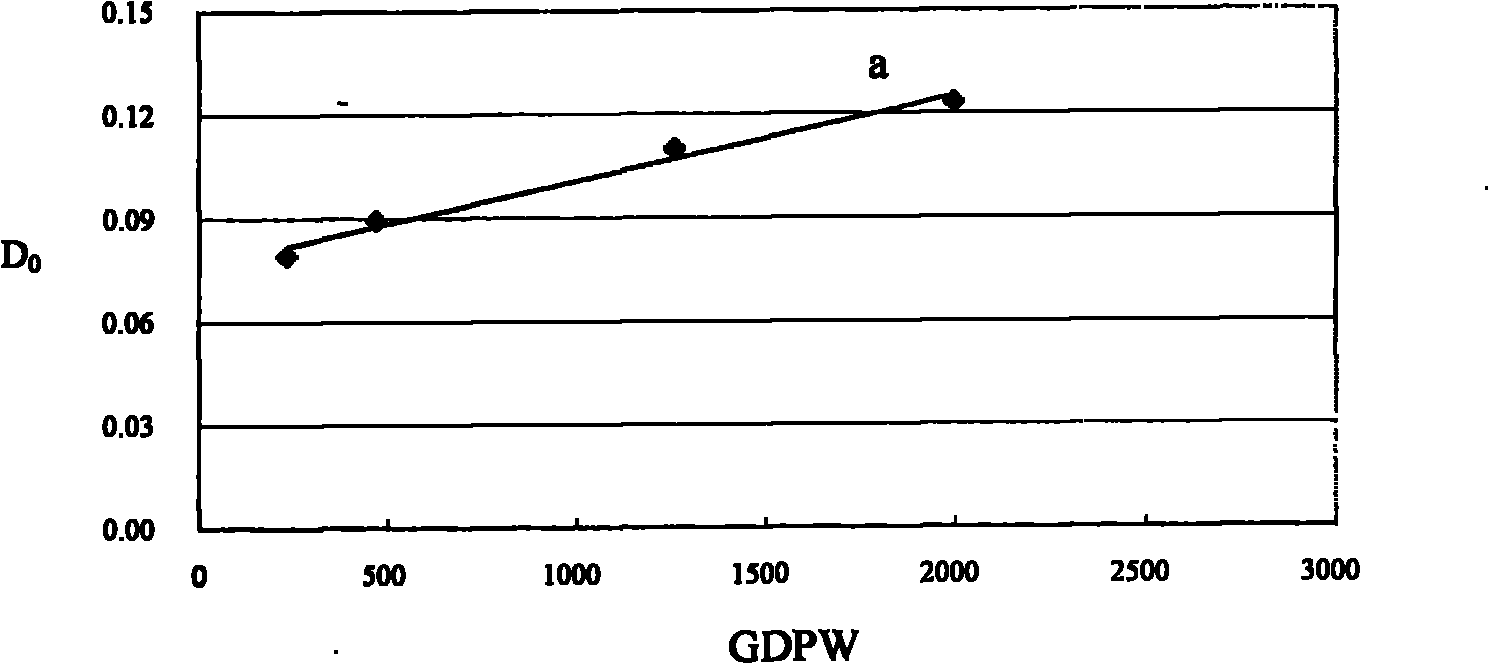

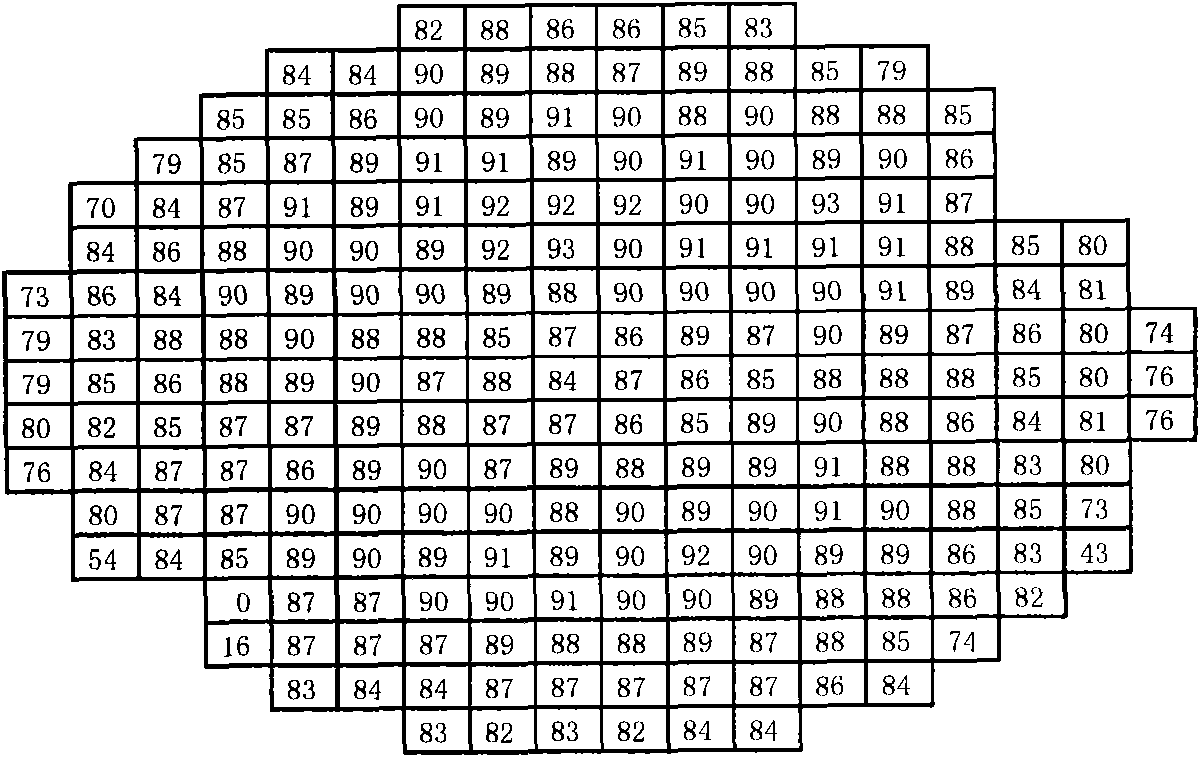

[0047] First, consider the impact of chip size on product yield, and use yield screening and misload rate compensation to remove the impact of chip size on product yield. Among them, yield screening solves the problem of wafer consistency, and misload rate compensation Solve non-defective failures. Secondly, the defect density correction factor is introduced based on the effect of the ratio of the storage area to the chip area on the defect density.

[0048] First, remove the impact of chip size on product yield, which is specifically divided into two aspects: wafer consistency screening and non-defect failure correction. specifically:

[0049] 1. Wafer consistency screening, get the corrected Yield’

[0050] The wafer consistency screening is divid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com