Cooperative operation system of automotive engineering training simulator

A collaborative working system and simulator technology, applied in the direction of instruments, educational appliances, teaching aids, etc., can solve problems such as inability to meet simulation training

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

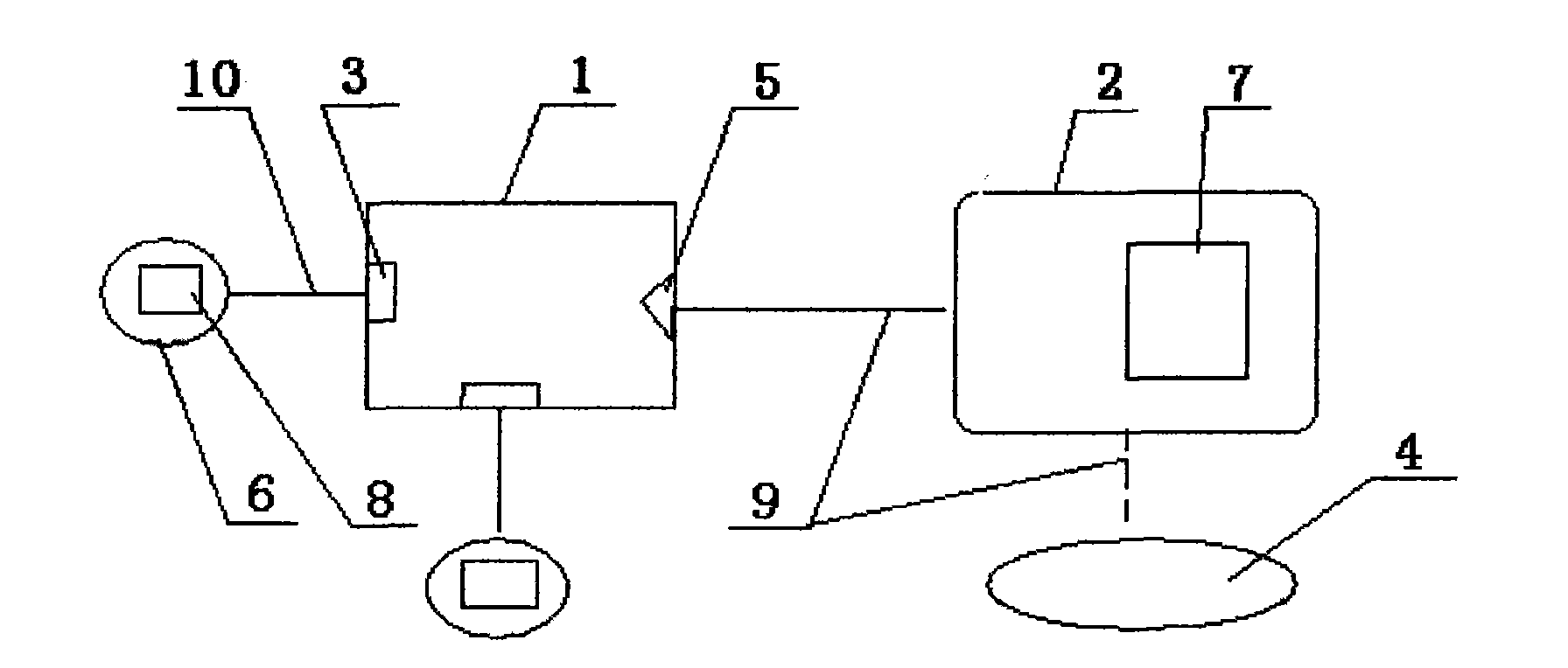

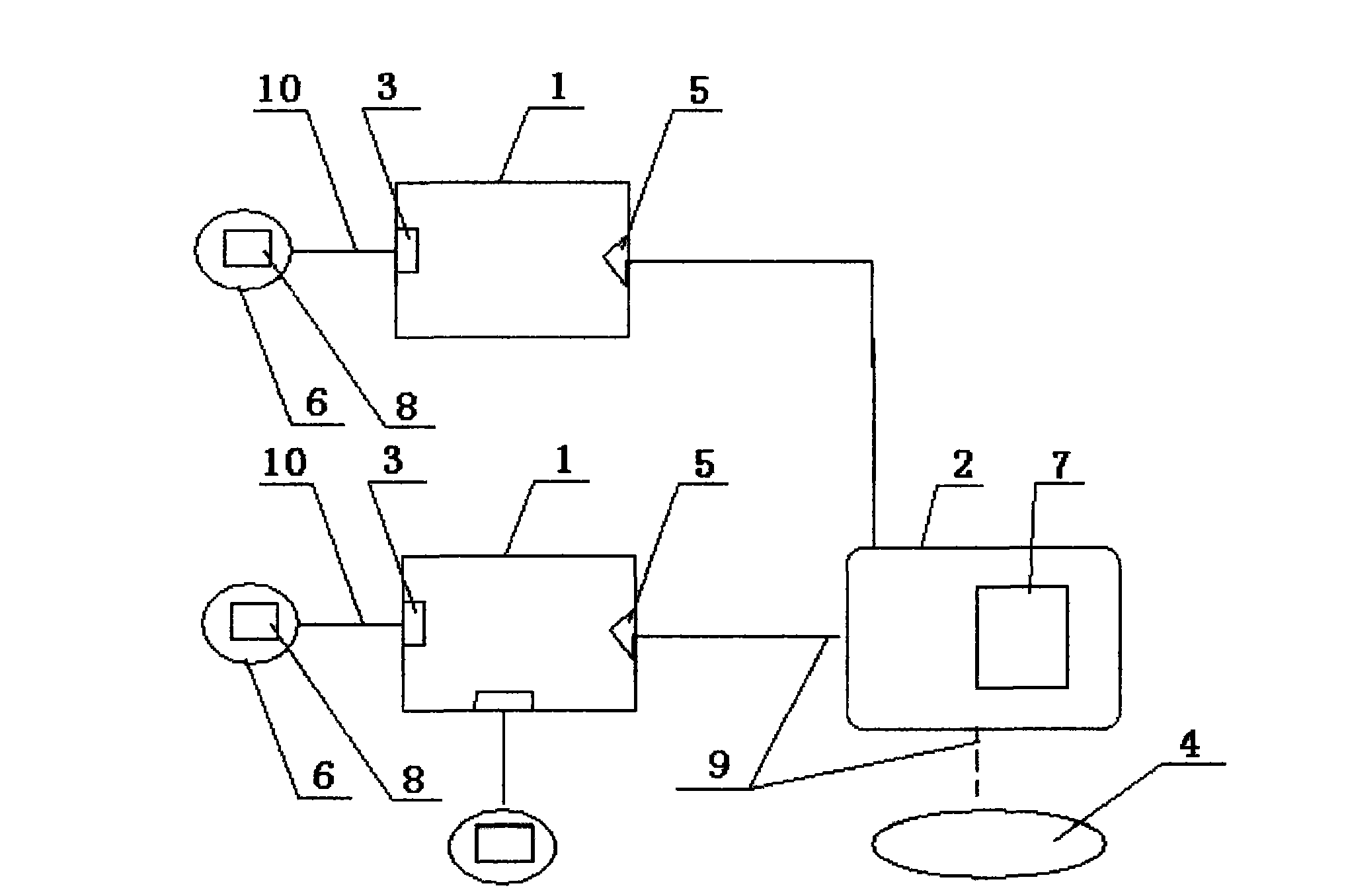

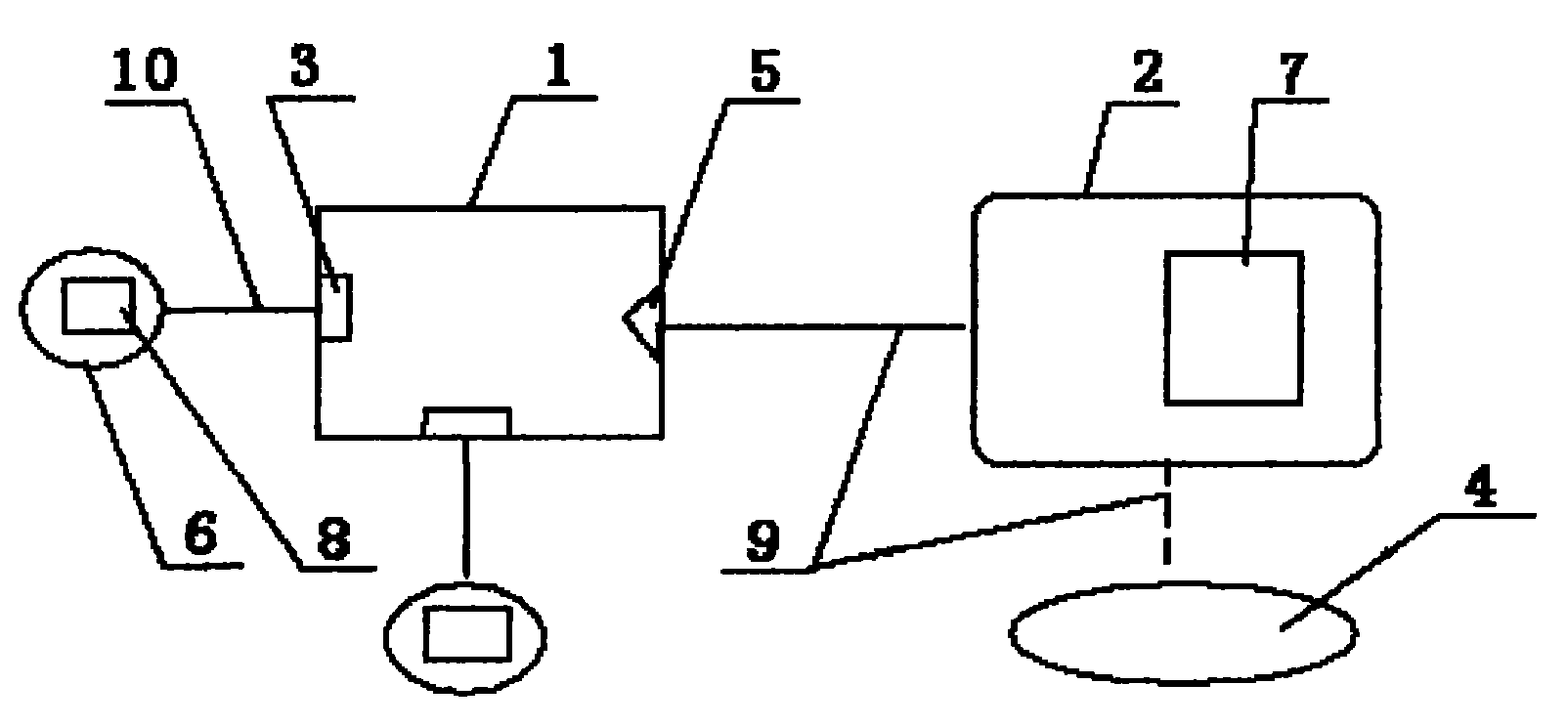

[0026] Such as Figure 1-2 , 1 is the automotive technology training simulator (training platform), 2 is the remote console, 3 is the network interface, 4 is the campus network, 5 is the communication interface, 6 is the test terminal, 7 is the multimedia animation teaching software and other teaching Resources, 8 is the test panel, 9 is the network cable, 10 is the data cable.

[0027] A cooperative work system of an automobile training simulator, comprising an automobile technology training simulator 1, a test terminal 6, a communication interface 5 of the automobile technology training simulator 1 connected to a test terminal 6, and the test terminal 6 is provided with a belt There is a circuit diagram of the automotive technology training simulator 1 with a test port, and the information parameters of the automotive technology training simulator 1 can be obtained by operating the test port. The interface is connected to the remote console 2, and the operation of the remot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com