Device and method for realizing alignment-deviation measurement in photoetching technology

A technology of alignment deviation and photolithography, which is applied in the photomechanical process of photomechanical processing of originals, optics, and pattern surfaces, and can solve the problems of difficult reading of photolithography vernier scales.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

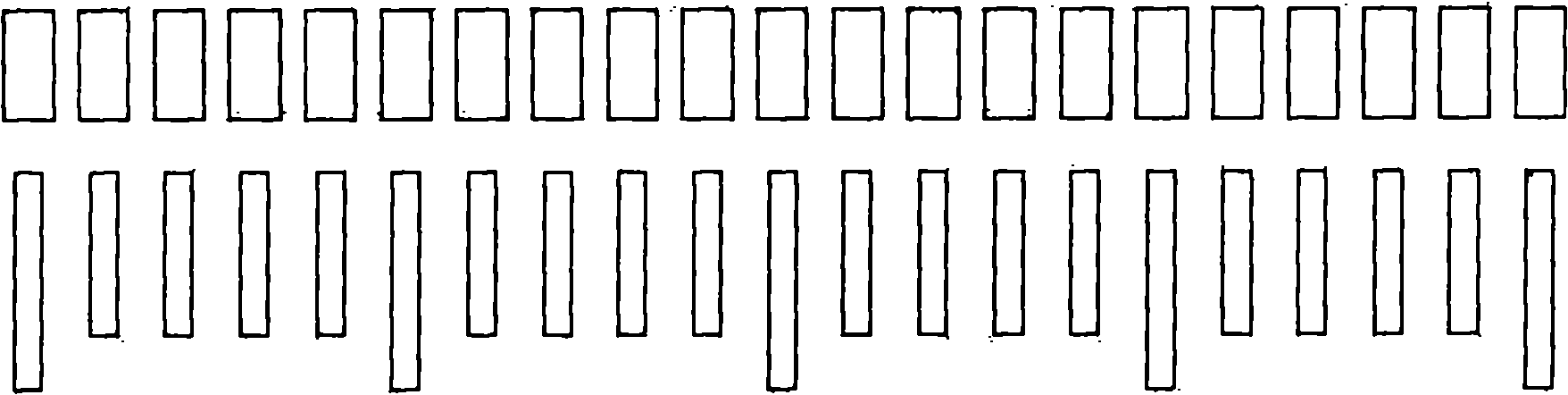

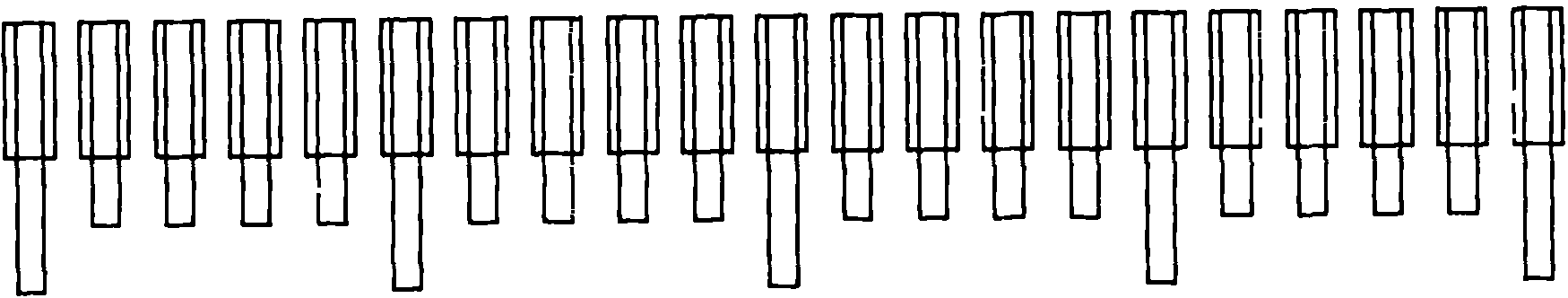

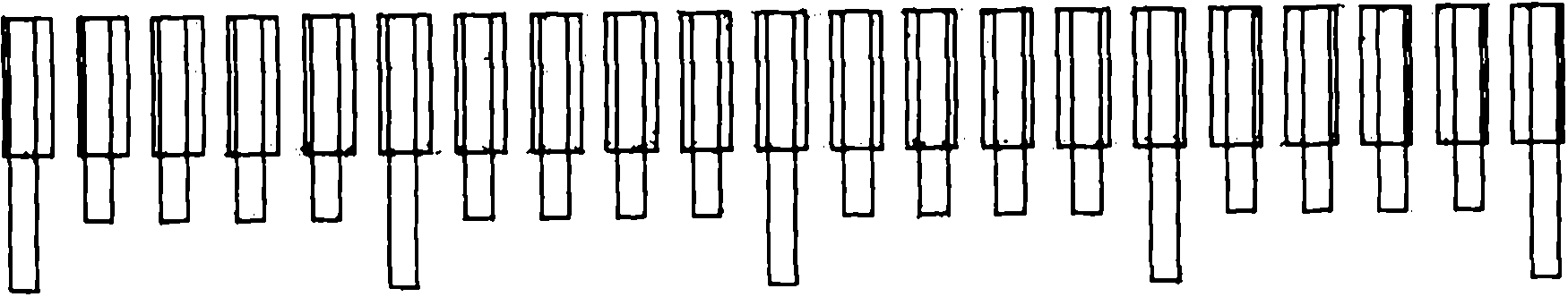

[0043] An embodiment of the present invention provides a method for generating a photolithography vernier, the method comprising: arranging a plurality of short teeth of the vernier in the pattern of the first layer of photoresist, and the short teeth of the vernier are arranged at equal intervals; A plurality of long teeth of the vernier ruler are set in the stereotype pattern, and the long teeth are arranged at equal intervals; when the first layer of photoresist pattern and the second layer of photoresist pattern overlap, the long ruler teeth and short ruler teeth are arranged alternately, and the short ruler teeth The width of the tooth is equal to the distance between two adjacent long chi teeth; the long chi teeth in the center of the long chi teeth are taken as the origin, and the long chi teeth at the positive and negative ends of the origin move corresponding distances to the two ends respectively with the origin as the center, and the long chi teeth The tooth and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com