Heavy-current sampling resistor

A technology for sampling resistors and large currents, which is applied in the direction of measuring current/voltage, resistors, resistor terminals/electrodes, etc., and can solve the problem of fewer samples of sampling resistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

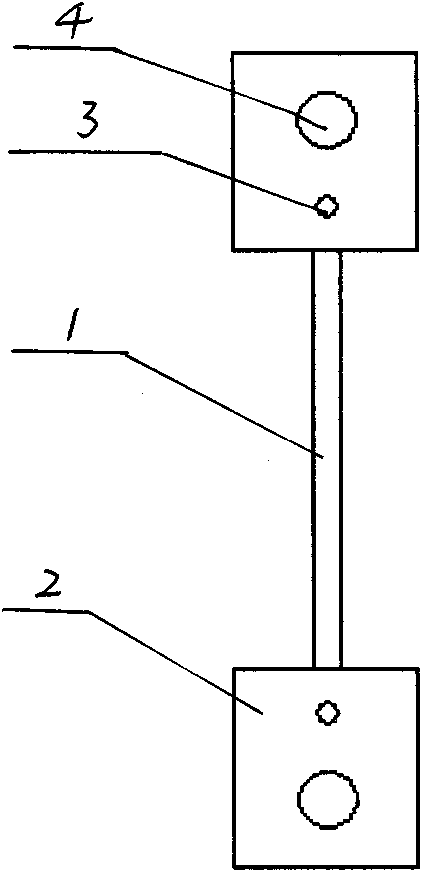

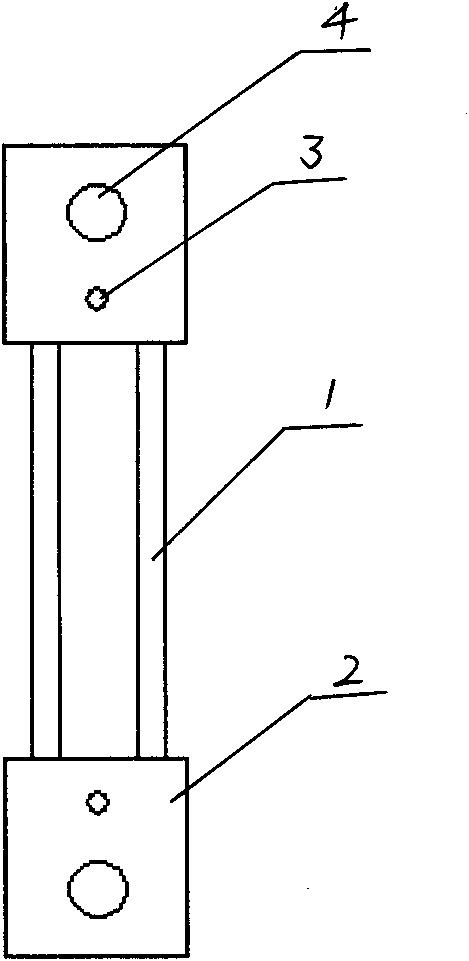

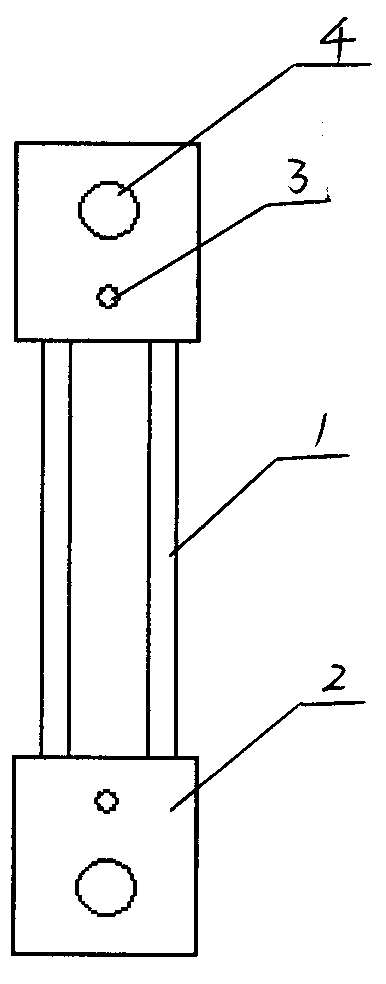

[0009] Such as figure 1 and figure 2 As shown, both ends of a single or double constantan wire 1 are connected to a brass sampling terminal 2, and the two brass sampling terminals are respectively provided with a 4mm data line hole 3 and a 6mm fixing hole 4. Among them, the single type is suitable for small current; the double type is suitable for large current.

[0010] The present invention is designed for a relatively large current of 25A--125A, and is suitable for connecting cable joints and sampling data lines. The two ends are made of brass material with good conductivity, and the middle is made of constantan wire. You can choose wires of different thickness to make sampling resistors with different currents.

[0011] The above-described embodiments are only described to the preferred implementation of the present invention, and are not intended to limit the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com