Two-component metering valve

A metering valve, two-component technology, applied in valve details, multi-port valves, valve devices, etc., can solve the problems of easy wear of the sealing ring gasket, slow dispensing speed, inconvenience, etc., to achieve the sealing structure is not easily damaged, functional More diverse and clean effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

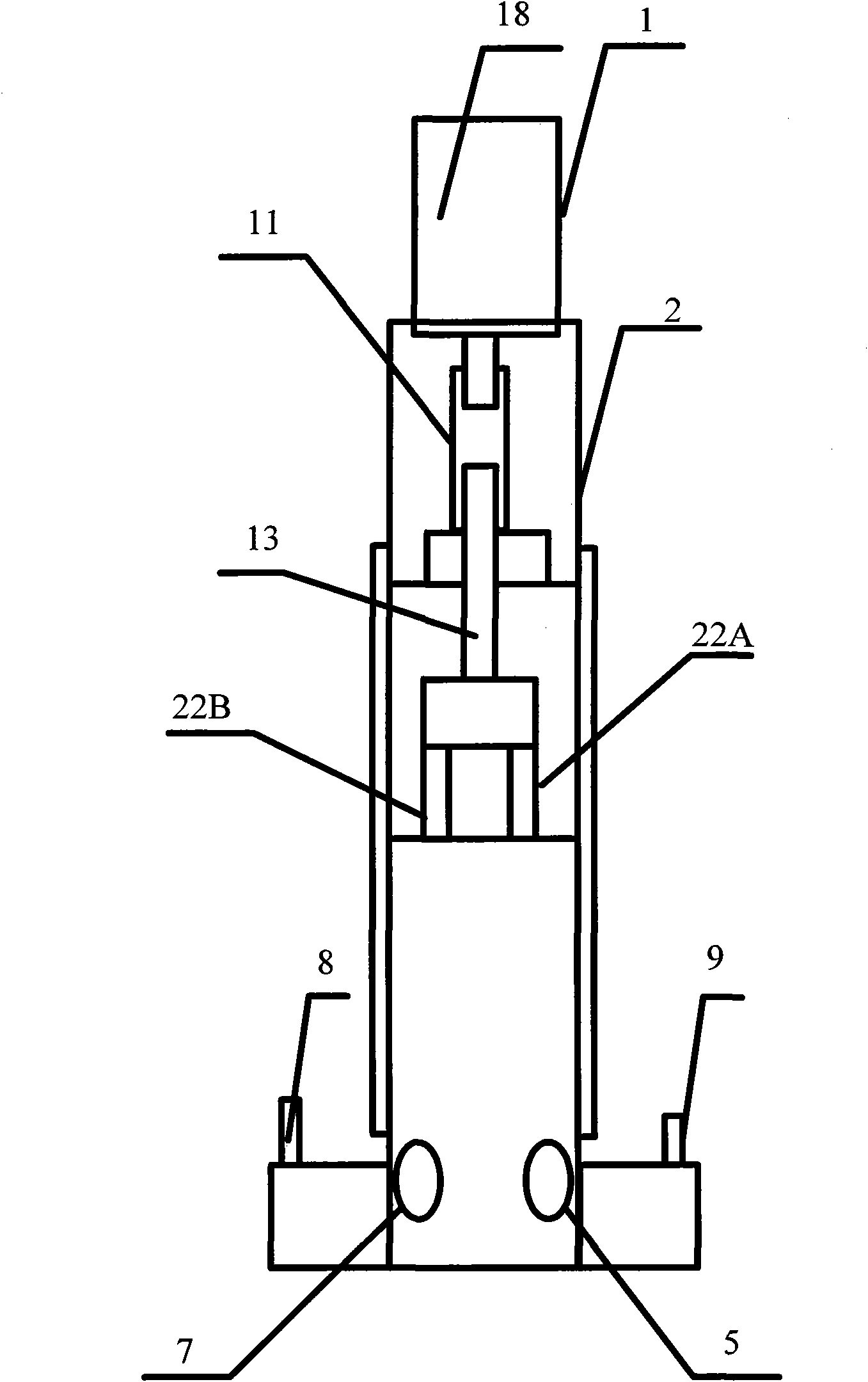

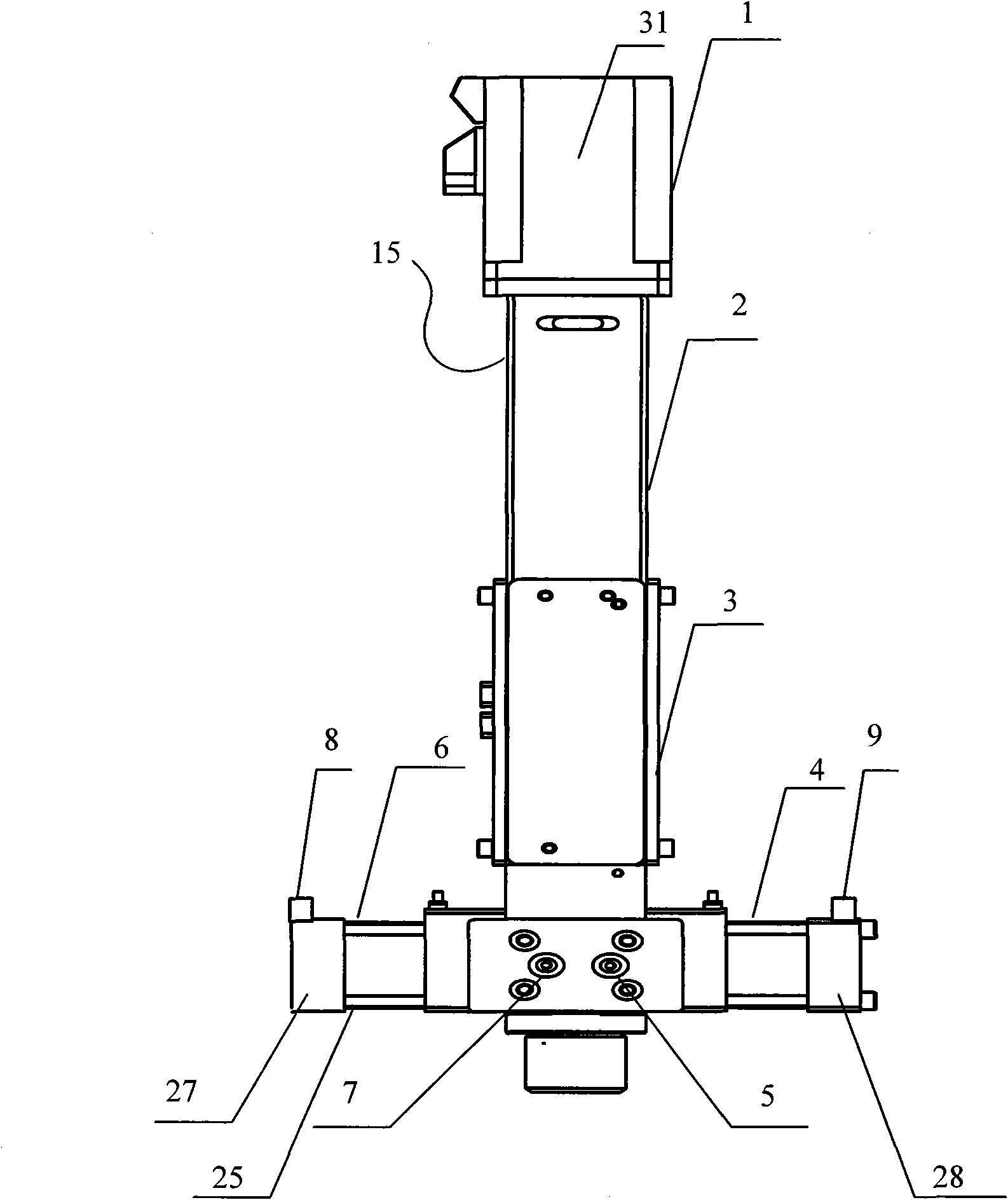

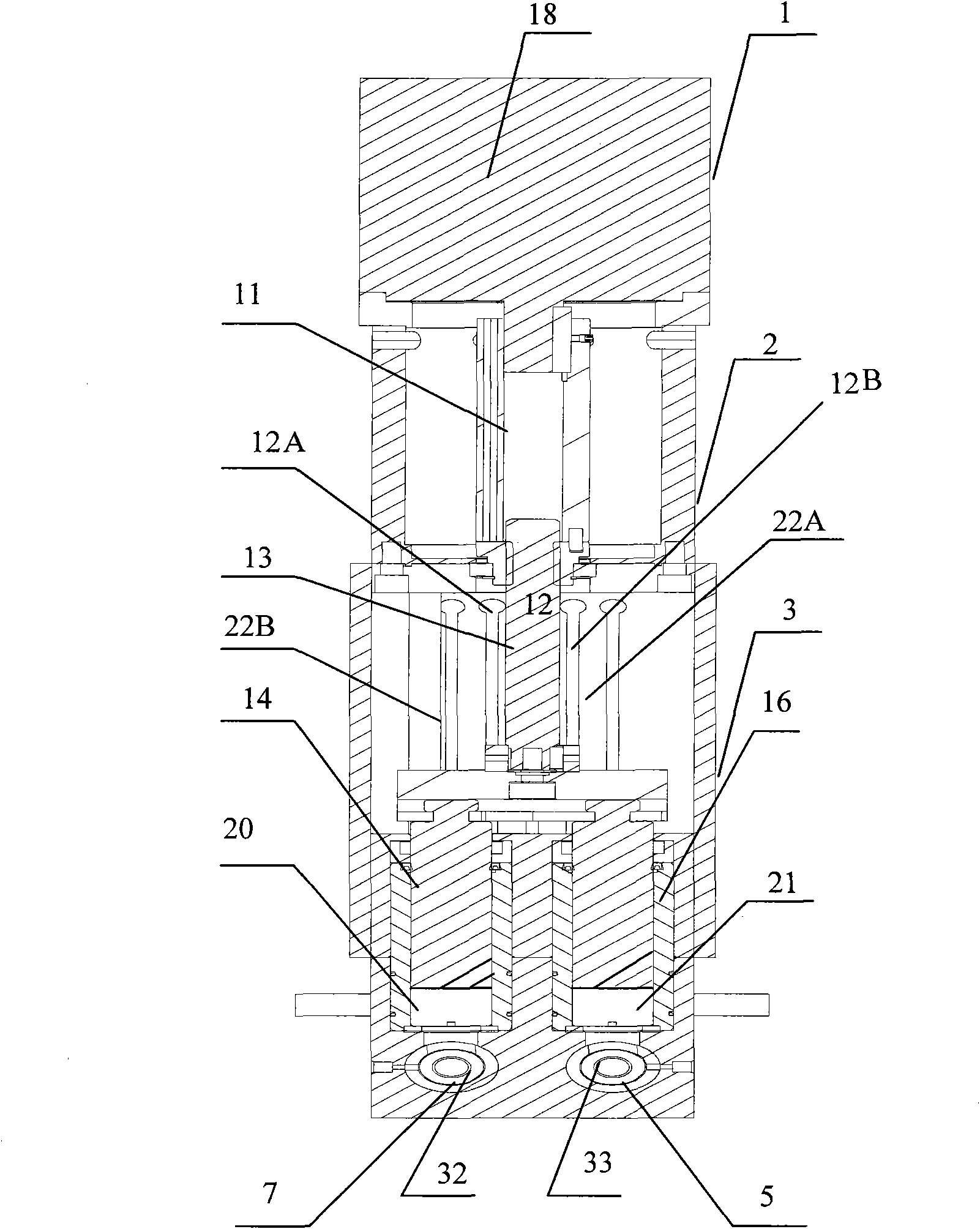

[0030] Such as figure 1 , figure 2 , image 3 As shown, a valve body includes an upper valve body 1, a lower valve body 3, and a material inlet and outlet control device 6. The upper valve body 1 and the lower valve body 3 are connected by a fixing device, and the upper valve body 1 includes an upper valve body. Shell and the driving device 18 arranged on the upper valve body;

[0031] The lower valve body 3 is arranged below the upper valve body 1, and at least one inlet and outlet control device 6 is arranged on the lower valve body 3,

[0032] Between the upper valve body 1 and the lower valve body 3, a transmission device 11 and a material feeding and discharging actuator are arranged,

[0033] The driving device is connected to the upper part of the material in and out actuator through the transmission device, the lower part of the material in and out of the actuator is connected to the first end of all the living rods, and the second end of each living rod is connect...

Embodiment 2

[0045] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the driving device arranged above the upper valve body 1 is a pneumatic driving device. When the driving mechanism in the upper valve body shell is a pneumatic driving device 1A; The head of the body is provided with an adjustment knob 41, and a cylinder and a transmission shaft are arranged in the upper valve body. The head of the transmission shaft is a cross-shaped head, and the cross-shaped head is arranged in the cylinder. The cross-shaped head is connected to the adjustment knob, the middle part of the transmission shaft is arranged in the transmission shaft channel, and the tail of the transmission shaft is connected to the connecting plate through a connecting device;

[0046] The cross-shaped head is arranged in the cylinder 62A, the cross-shaped head is connected with the adjustment knob 41, the middle part of the transmission shaft 48A is arranged in the first channel 20A, and the transmission ...

Embodiment 3

[0065] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, on the basis of the above-mentioned implementation examples, the two-component metering valve is usually used in conjunction with a glue dispenser or a desktop robot or manipulator.

[0066] In the process of daily use, the two-component metering valve is usually installed on the fixed end of the glue dispenser or manipulator or robot to complete the glue spraying process. In this example, the selected driving device is a pneumatic driving device;

[0067] First adjust the head adjustment knob that is arranged on the upper valve body, so that the size of the volume of the cylinder 28A in the upper valve body meets the needs of the transmission device to move up and down. The head of the transmission device is a cross-shaped head, and the cross-shaped head The part is arranged in the cylinder 22A, and a first air inlet 62A and a second air inlet 43A are arranged on the upper side of the upper valve body, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com